Composite culture medium for producing chitosanase through fermentation

A technology of chitosanase and medium, applied in the field of microorganisms, can solve the problems of high cost of medium, large investment in equipment, fast speed, etc., and achieve the effects of improving fermentation level, no environmental impact, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

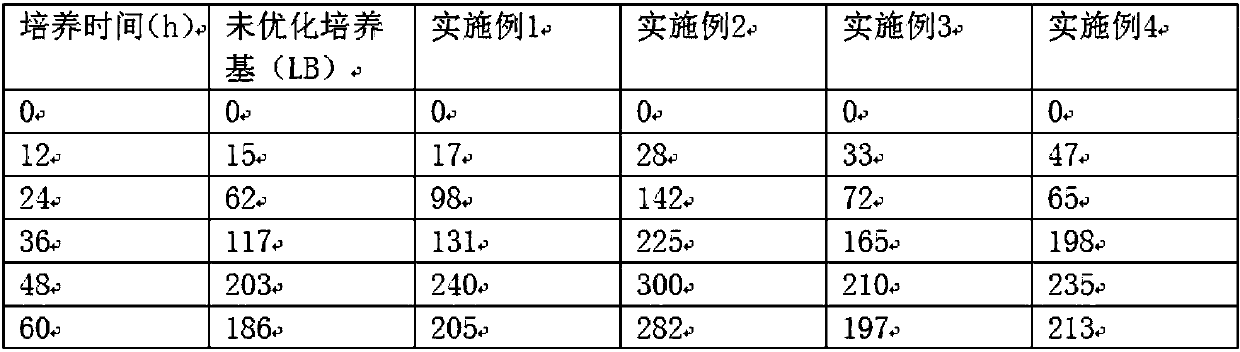

Embodiment 1

[0014] Bacillus culture medium for the production of chitosanase by fermentation. 1000mL shake flask, the culture medium is composed of: specific molecular weight (8000-10000Da) chitosan 5g / L; yeast extract powder 12g / L; glucose 10g / L; inositol 0.01g / L; biotin 0.05mg / L; hydrochloric acid Thiamine 8g / L; riboflavin 3.5g / L; vitamin B12 4.2mg / L, pH 6.5. Seed solution was seeded for 24 hours, inoculated with 10%, filled with 10ml / 250mL, rotated at 175rpm / min, cultivated at 37°C for 48 hours, and the chitosanase activity reached 240U / ml.

Embodiment 2

[0016] Bacillus culture medium for the production of chitosanase by fermentation. 1000mL shake flask, the culture medium is composed of: specific molecular weight (8000-10000Da) chitosan 7.5g / L; yeast extract powder 10g / L; glucose 10g / L; inositol 0.03g / L; biotin 0.05mg / L; Thiamine hydrochloride 7g / L; riboflavin 4.0 / L; vitamin B12 3.5mg / L, pH value 6.5. Seed solution seed age is 24 hours, 10% inoculation, liquid volume 10ml / 250mL, rotating speed 200rpm / min, cultured at 37°C for 48 hours, and the chitosanase activity reaches 300U / ml.

Embodiment 3

[0018] Bacillus culture medium for the production of chitosanase by fermentation. 1000mL shake flask, the culture medium is composed of: specific molecular weight (8000-10000Da) chitosan 10g / L; yeast extract powder 8g / L; glucose 10g / L; inositol 0.01g / L; biotin 0.03mg / L; hydrochloric acid Thiamine 8g / L; Riboflavin 5.0 / L; Vitamin B12 3.5mg / L, pH 6.0. Seed solution seed age is 24 hours, 10% inoculation, liquid volume 10ml / 250mL, rotating speed 200rpm / min, cultured at 37°C for 48 hours, and the chitosanase activity reaches 210U / ml.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap