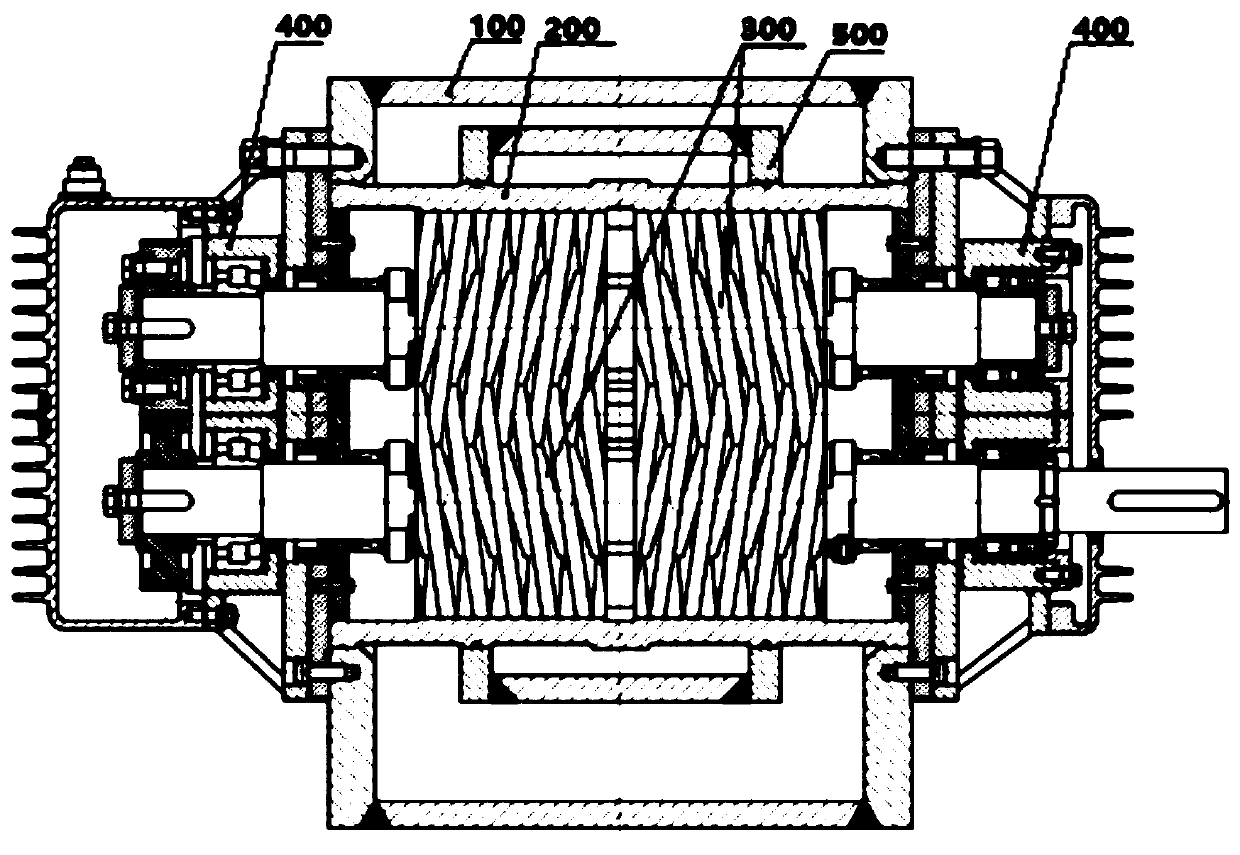

High-pressure dual-screw pump body pressing tool and high-pressure dual-screw pump static pressure test method

A technology of twin-screw pump and pump body, which is applied in the field of high-pressure twin-screw pump body pressing tooling and high-pressure twin-screw pump static pressure test field, can solve the problem of inability to accurately judge whether the working capacity of the low-pressure area inside the pump body meets the standard, etc. energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

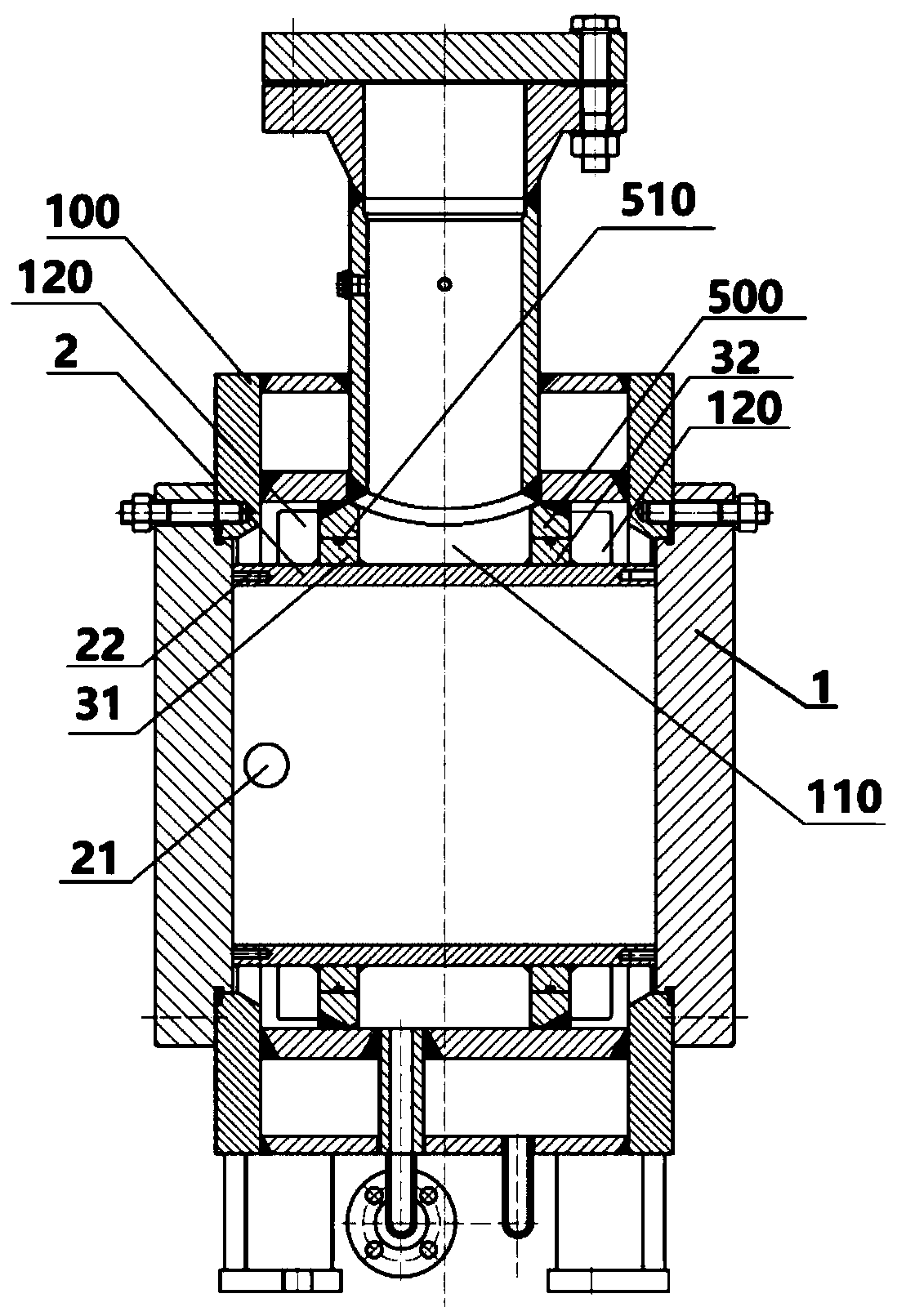

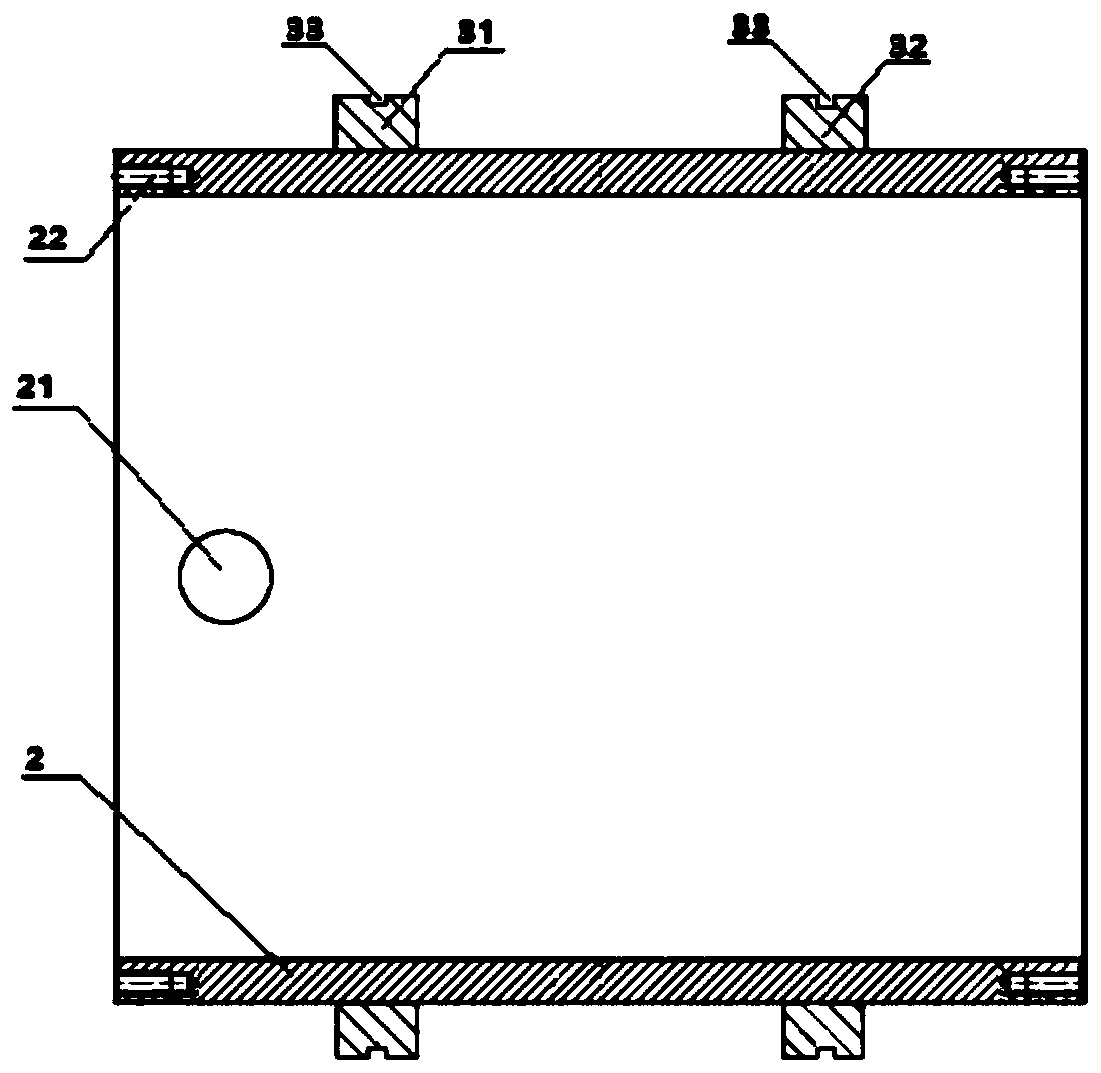

[0055] Please also refer to Figure 2 to Figure 4 , as a specific embodiment of a high-pressure twin-screw pump pump body pressing tooling provided by the present invention, the sealing assembly includes a first sealing ring 31 and a second sealing ring 32; wherein, the first sealing ring 31 and the second sealing ring 32 are fixedly sleeved on the spacer 2, and are located on the inner side of each supporting ring 500 one by one; the first sealing ring 31 is used to connect with one of the supporting rings 500, and the second sealing ring 32 is used to connect with the other The support rings 500 are connected.

[0056] When preparing the sealing assembly, the sizes of the first sealing ring 31 and the second sealing ring 32 are determined according to the sizes of the two supporting rings 500 in the pump body 100 . In the process of installing the spacer 2, if the sizes of the two support rings 500 are different, the sizes of the first sealing ring 31 and the second sealing ri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap