Method for removing As (III) in wastewater through enhanced coagulation

A waste water and coagulation technology, applied in the field of water treatment, can solve problems such as low efficiency, high cost, and increased oxidant input, and achieve the effects of improving the pH environment, saving costs, and improving coagulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

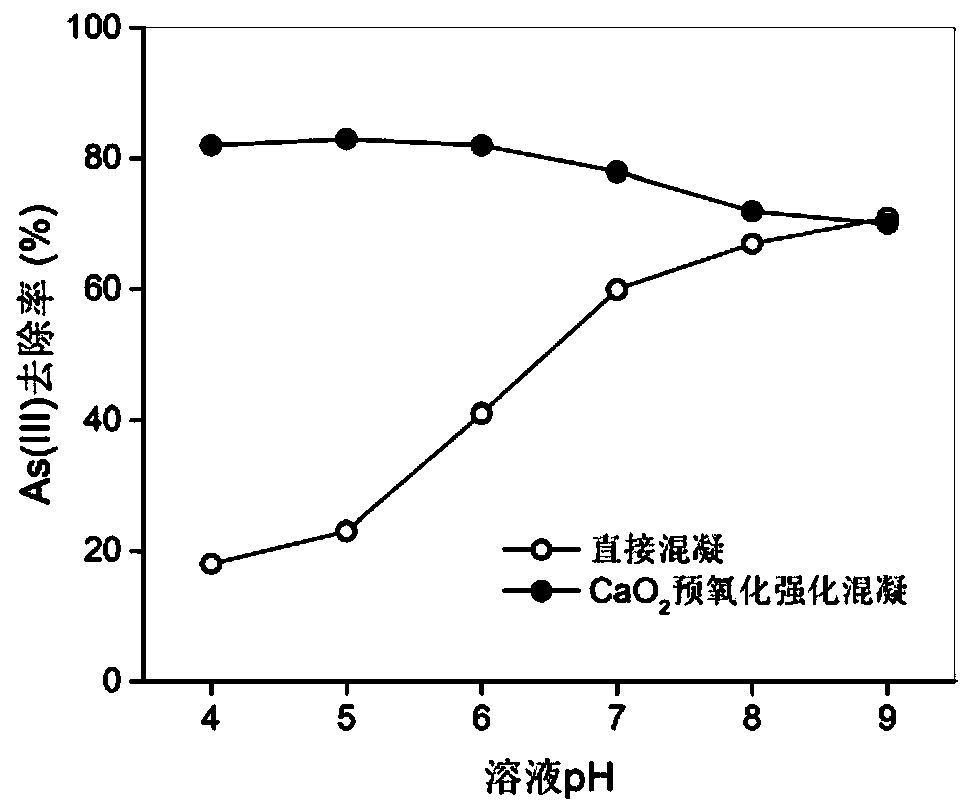

[0044] Step 1), add to the water samples with the As(III) content of 1.0mg / L whose initial pH values are pH=4, pH=5, pH=6, pH=7, pH=8, and pH=9 respectively. 15mg / L of CaO 2 , continue stirring for 5min at a speed of 200rpm; after the end, measure the CaO 2 For the oxidation rate of As(III), after testing, when the initial pH values are pH=4, pH=5, pH=6, pH=7, pH=8, pH=9, CaO 2 The oxidation rates to As(III) were 32%, 34%, 51%, 63%, 72% and 85%, respectively. i.e. in step 1) CaO 2 A pre-oxidation effect (incomplete oxidation) occurs on As(III).

[0045] Step 2), adding 50mg / L of titanium sulfate to the water sample after the treatment in the above step 1) respectively, stirring at a speed of 200rpm for 5min, adjusting the speed to 40rpm, stirring continuously for 10min, and measuring the supernatant after standing for 20min. The residual arsenic concentration in the solution.

[0046] At the same time, a comparison experiment of direct coagulation was set up for th

Embodiment 2

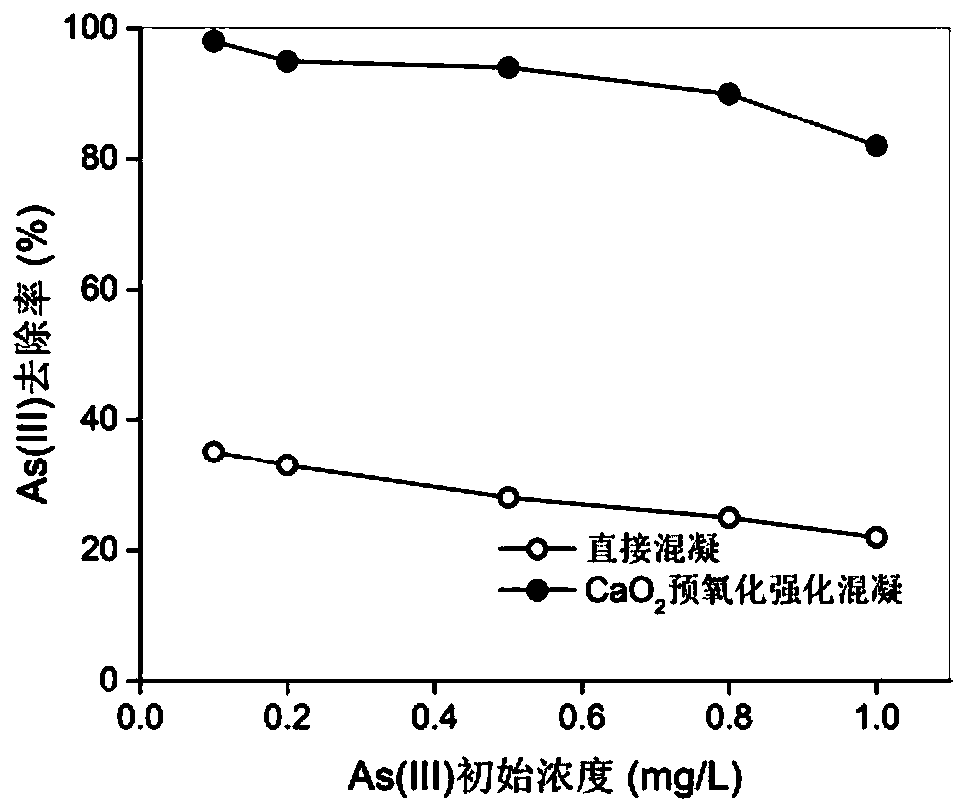

[0048] Step 1), add 20mg / L CaO to the water sample (pH=5.0) containing As(III) 2 , continue stirring for 2.5min at a speed of 250rpm;

[0049] Step 2), add 80mg / L of titanium sulfate coagulant to the above water sample, stir at 400rpm for 3min, adjust the speed to 60rpm, continue stirring for 20min, and measure the remaining arsenic in the supernatant after standing for 30min. concentration.

[0050] According to the above experimental steps, five groups of parallel experiments with initial As(III) concentrations of 0.1, 0.2, 0.5, 0.8 and 1.0 mg / L were set respectively, and CaO in each group was determined after step 1). 2 Oxidation rate of As(III); the results are: CaO 2 The oxidation rates of As(III) were 81%, 82%, 62%, 42% and 35%, respectively.

[0051] At the same time, a comparison experiment of direct coagulation was set up for five groups of parallel experiments, that is, only the coagulation experiment of step 2) was performed under the same conditions, and CaO

Embodiment 3

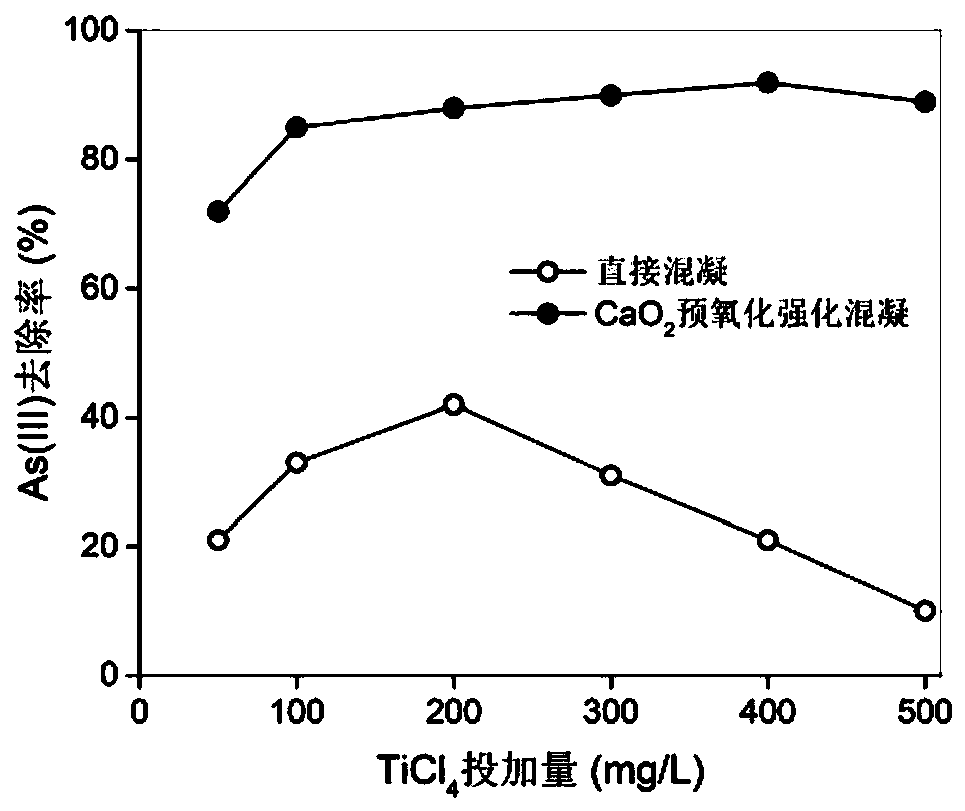

[0053] Step 1), add 100mg / L CaO to the water sample (pH 7.0) with As(III) content of 1.0mg / L 2 , continue stirring for 2min at a rotating speed of 500rpm, after step 1), measure the CaO 2 The oxidation rate to As(III) was 82%.

[0054] Step 2), adding titanium tetrachloride coagulant to the above water sample, stirring at 500rpm for 3min, adjusting the speed to 80rpm, stirring continuously for 30min, and measuring the residual arsenic concentration in the supernatant after standing for 40min.

[0055] Aiming at the above steps, five groups of parallel experiments were set up with the dosage of titanium tetrachloride being 50, 100, 200, 300, 400, and 500 mg / L, respectively. The coagulation experiment of step 2). Under the same conditions, compare CaO 2 The removal efficiency of As in the pre-oxidation enhanced coagulation and the direct coagulation process is compared, and the comparison results are as follows image 3 The results show that even if the dosage of coagulan

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap