Packaging method and LED packaging structure

A technology of LED encapsulation and encapsulation method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem that the amount of glue cannot be effectively controlled, and achieve the effect of improving the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 example

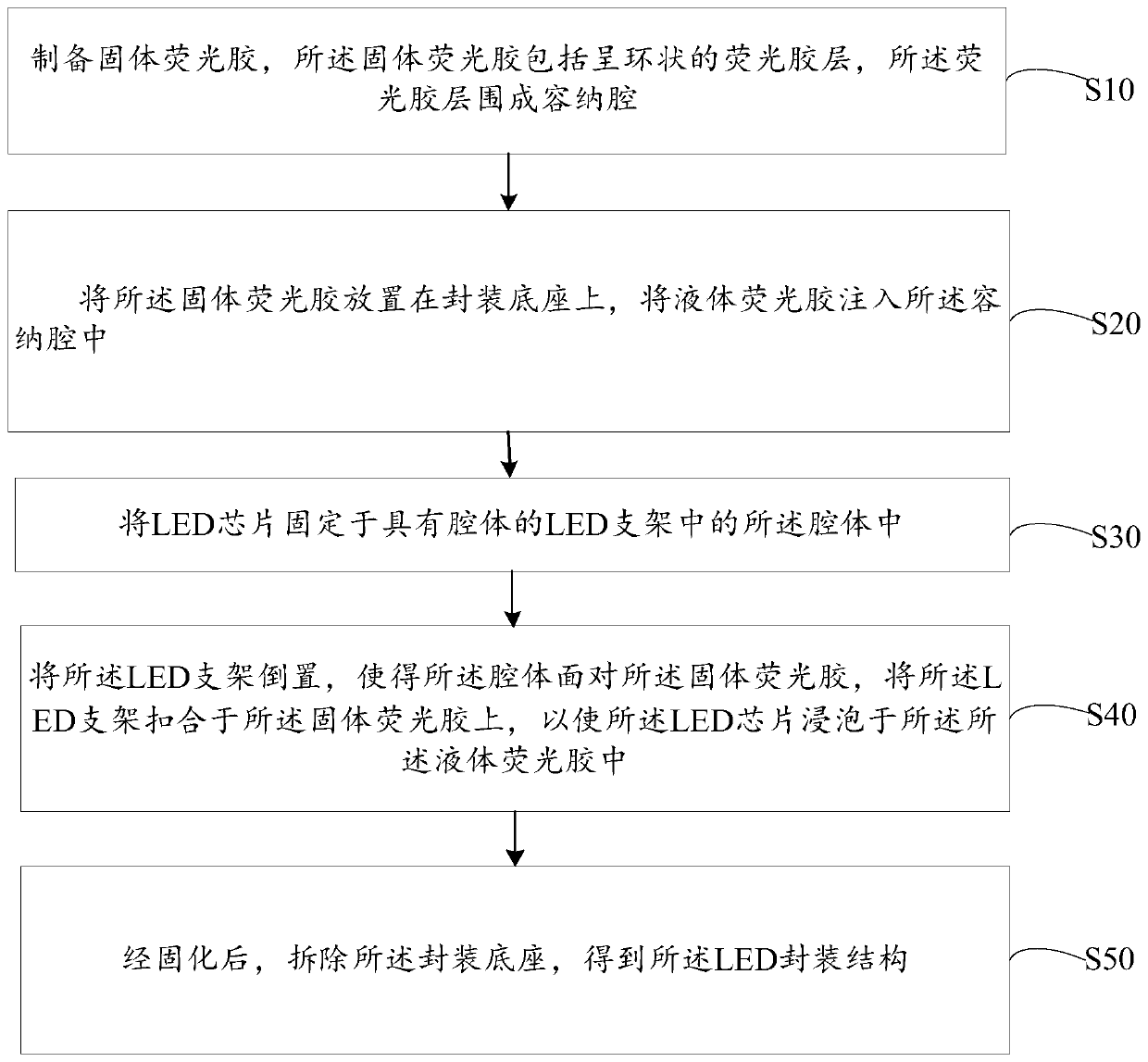

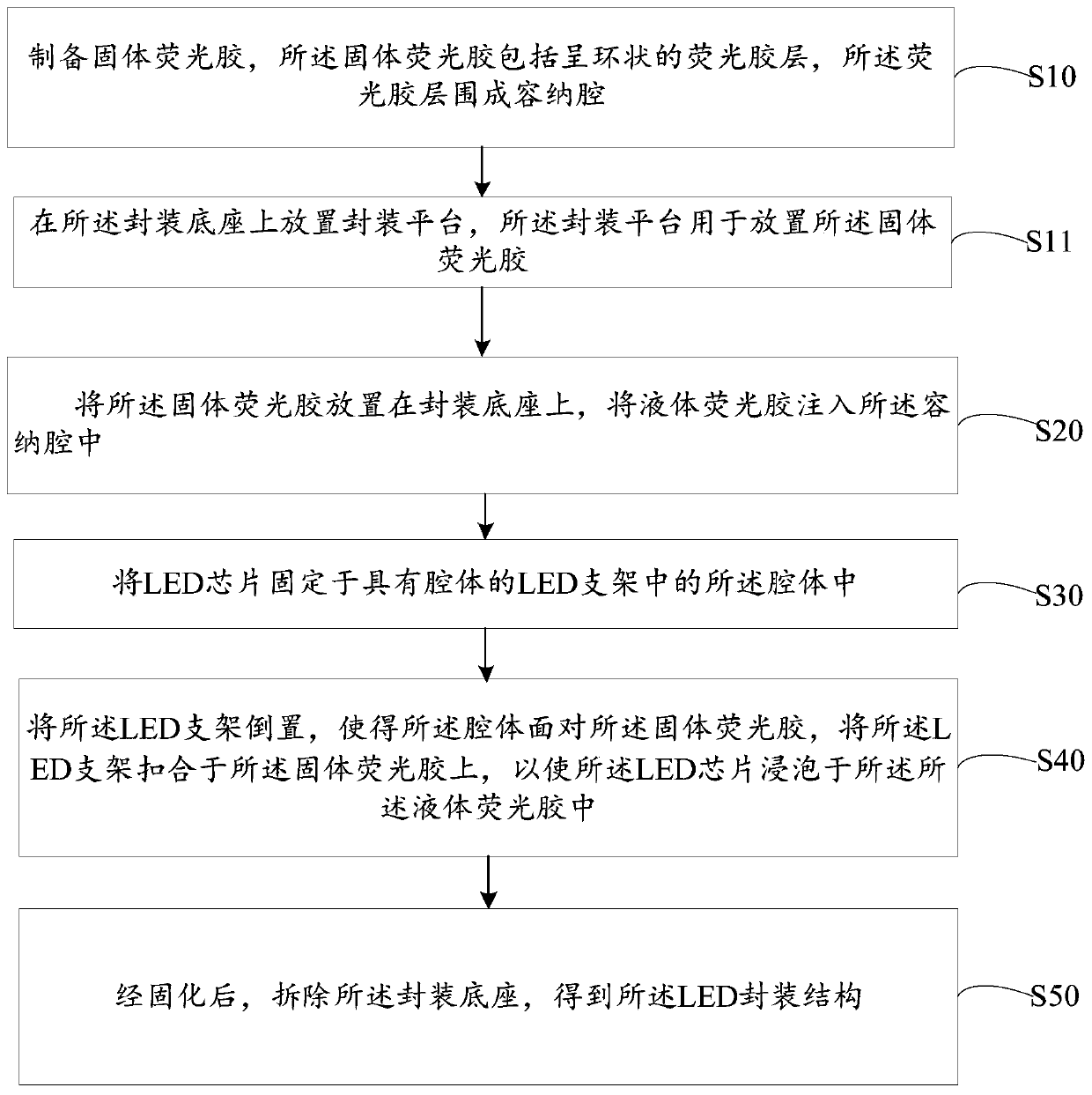

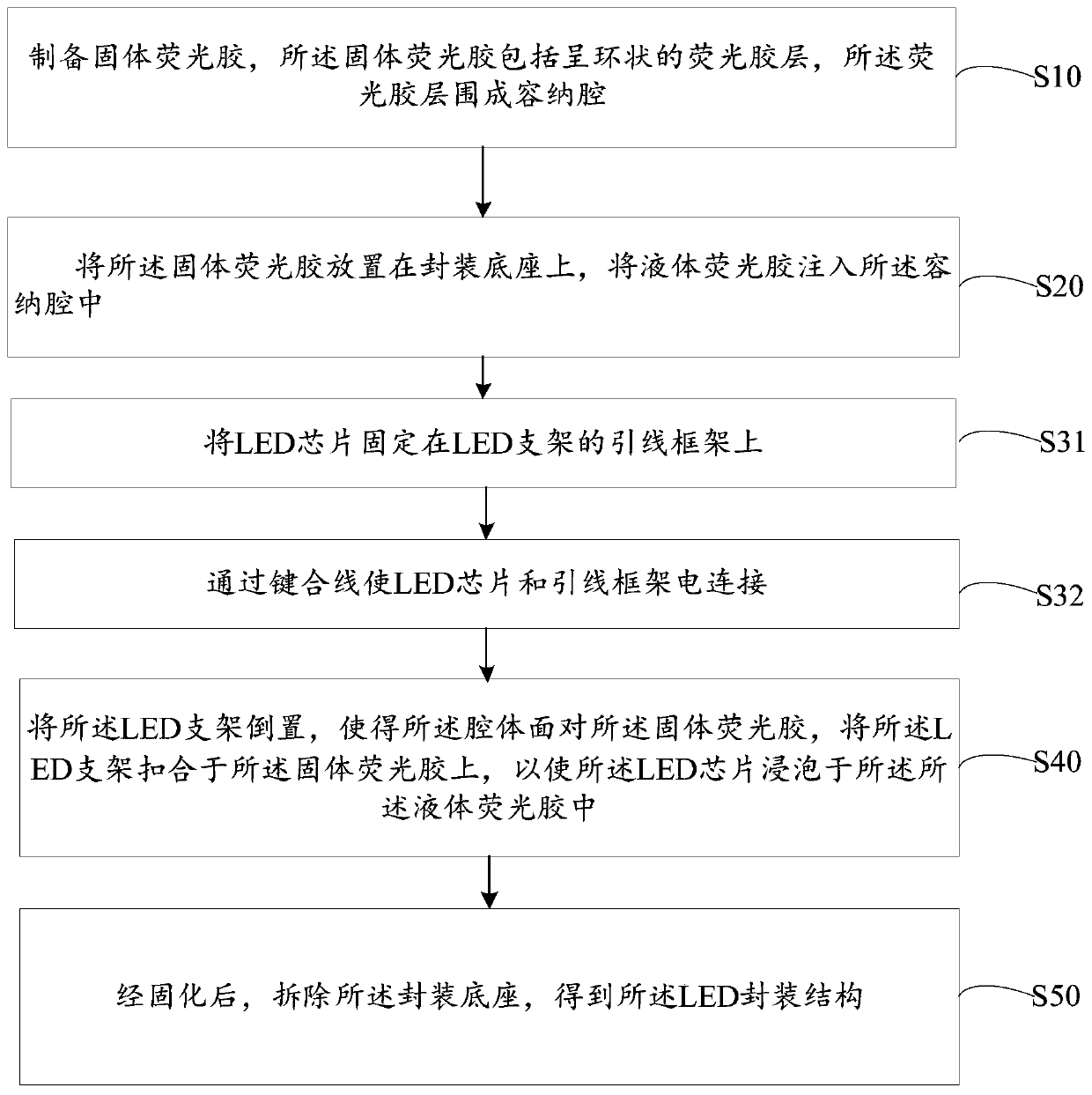

[0046] like figure 1 As shown, in the first embodiment of the packaging method provided by the present invention, the method includes the following steps:

[0047] Step S10, preparing the solid fluorescent glue 10, the solid fluorescent glue 10 includes a ring-shaped fluorescent glue layer, and the fluorescent glue layer encloses the accommodation cavity 11;

[0048] In the present invention, first prepare the solid fluorescent glue 10, so that the solid fluorescent glue 10 is equivalent to the role of the retaining wall, so that when the first liquid fluorescent glue 30 is injected into the accommodation cavity 11 of the solid fluorescent glue 10, the first liquid fluorescent glue 30 will be blocked by solid fluorescent glue 10.

[0049] Step S20, placing the solid fluorescent glue 10 on the packaging base 20, and injecting the first liquid fluorescent glue 30 into the accommodation cavity 11;

[0050] When injecting the first liquid fluorescent glue 30 into the solid fluoresc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap