Preparation method of medical polyurethane with adjustable surface wettability

A polyurethane and wettability technology, applied in the field of polymer preparation, can solve the problem of no longer having a modified layer, and achieve the effect of stable and adjustable surface wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

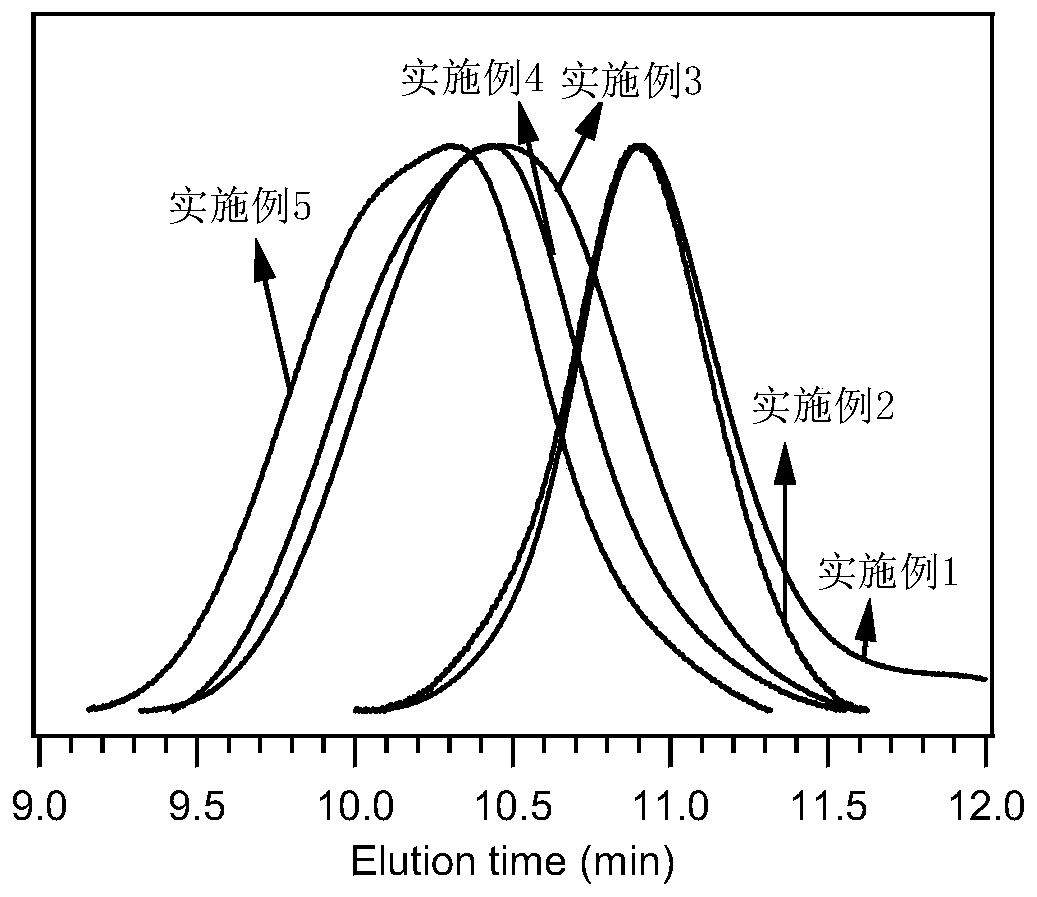

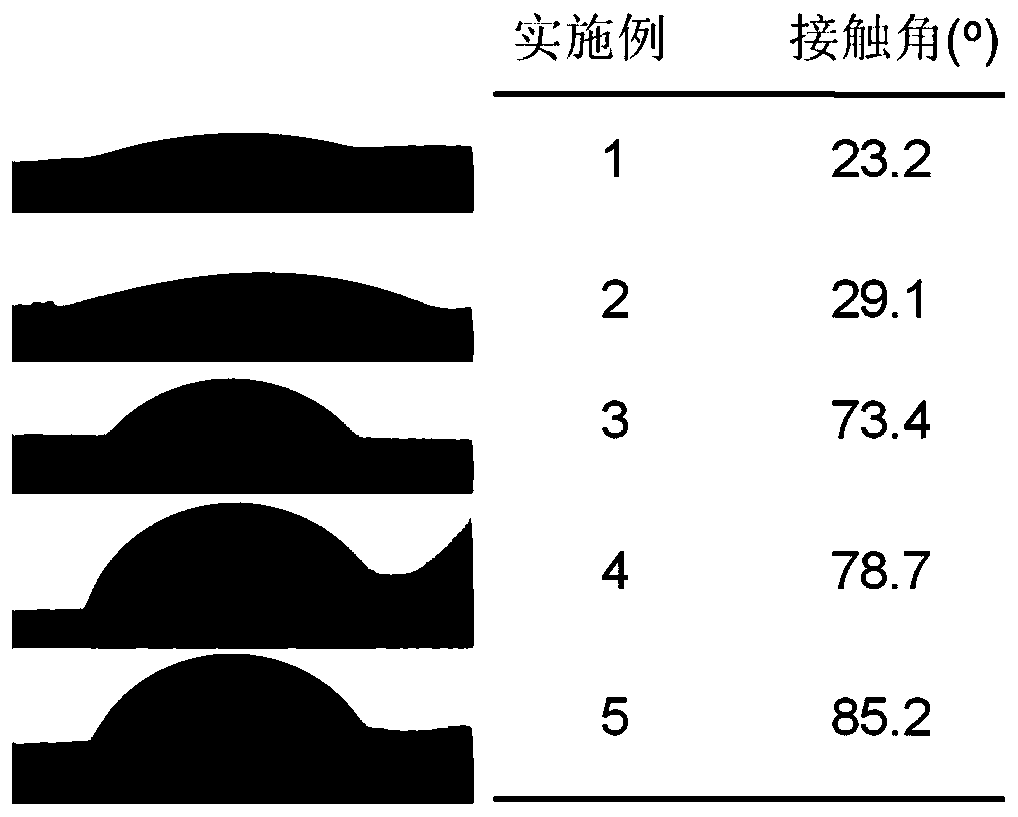

[0073] Under the protection of nitrogen at room temperature, add the dried PCL dibasic alcohol (R=-(CH 2 CH 2 O) 3 CH 3 , R'=-(CH 2 ) 6 -, degree of polymerization = 10, M n = 1,380 g / mol, M w / M n =1.14, product of Shenzhen Xin Element New Material Technology Co., Ltd.) 138g, heated until completely melted, then started stirring, added HDI16.8g and stannous octoate 40.5mg, and continued to stir for 2 hours. Take out product, measure number average molecular weight (M n =5,600g / mol) and molecular weight distribution (M w / M n = 1.31). Take a certain amount of product and melt it in a 2cm×2cm square glass dish, and measure the wettability of the bottom smooth surface after cooling (contact angle=23.2°).

Embodiment 2

[0075] Under the protection of nitrogen at room temperature, add the dried PCL dibasic alcohol (R=-(CH 2 CH 2 O) 3 CH 3 , R'=-(CH 2 ) 6 -, degree of polymerization = 20, M n = 2,520 g / mol, M w / M n =1.15, product of Shenzhen Xin Element New Material Technology Co., Ltd.) 126g, heated until completely melted, then started stirring, added HDI8.4g and stannous octoate 20.2mg, and continued to stir for 1.5 hours. Take out product, measure number average molecular weight (M n =7,300g / mol) and molecular weight distribution (M w / M n = 1.15). Take a certain amount of product and melt it in a 2cm×2cm square glass dish, and measure the wettability of the bottom smooth surface after cooling (contact angle=29.1°).

Embodiment 3

[0077] Under the protection of nitrogen at room temperature, add the dried PCL dibasic alcohol (R=-(CH 2 CH 2 O) 3 CH 3 , R'=-(CH 2 )6 -, degree of polymerization = 30, M n = 3,660 g / mol, M w / M n =1.16, product of Shenzhen Xin Element New Material Technology Co., Ltd.) 122g, heated until completely melted, then started stirring, added HDI5.6g and stannous octoate 13.5mg, and continued to stir for 2 hours. Take out product, measure number average molecular weight (M n =13,000g / mol) and molecular weight distribution (M w / M n = 1.36). Take a certain amount of product and melt it in a 2cm×2cm square glass dish, and measure the wettability of the bottom smooth surface after cooling (contact angle=73.4°).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap