Condensation water recovery pump mechanical seal cooling device

A technology for mechanical seals and cooling devices, which is applied to components, mechanical equipment, pumps, etc. of pumping devices for elastic fluids, and can solve problems such as bursting auxiliary seal rings, coking, and wear of mechanical seal friction pairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

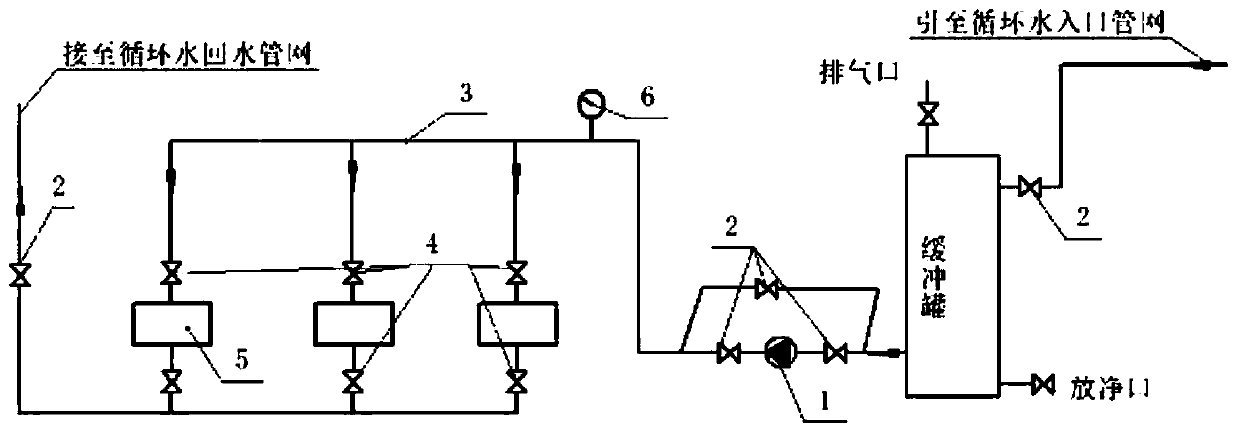

[0018] This embodiment proposes a condensate recovery pump mechanical seal cooling device, its structure is as follows figure 1 As shown, it is controlled by the cooling circulating water inlet pipeline, buffer tank, pipeline booster pump 1, bypass valve and control valve group 2, distributor 3, pressure gauge 6, mechanical seal cooling chamber 5, and the inlet and outlet of the mechanical seal cooling chamber The valve group 4 is composed of the cooling circulating water return pipeline.

[0019] Wherein, since cooling circulating water is used as the cooling medium, and the medium contains many impurities, a buffer tank is added before the inlet of the pipeline booster pump 1 . The cooling circulating water of the cooli

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap