Coating film forming matter with rapid surface drying performance and preparation method thereof

A technology of film formers and coatings, applied in the direction of coatings, etc., can solve the problems of not being able to meet the needs of fast surface drying, and achieve the effects of high glass transition temperature, good gloss and fullness, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

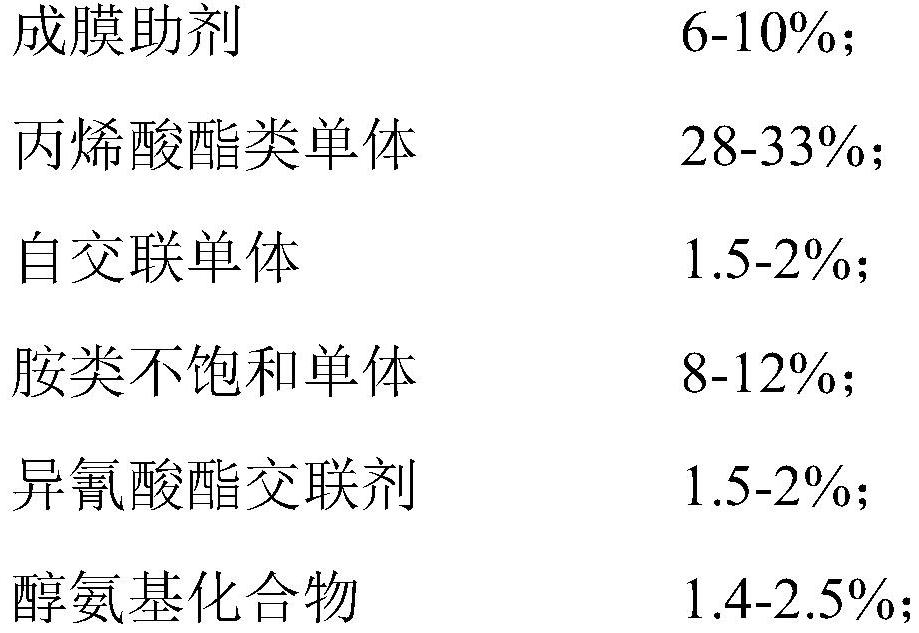

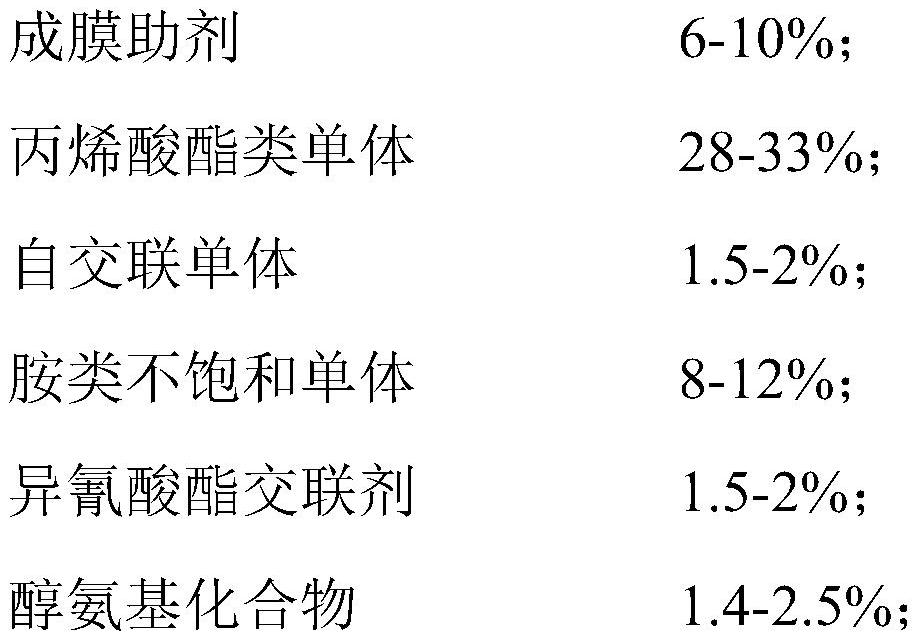

Method used

Image

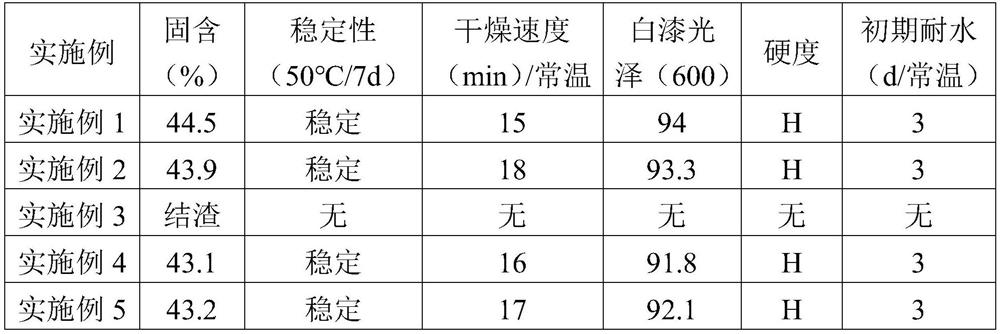

Examples

preparation example Construction

[0026] A method for preparing a coating film former with fast surface drying performance, comprising the following steps:

[0027] 1) Add film-forming aids to the reaction flask and raise the temperature to 150-155°C;

[0028] 2) mixing acrylate monomers, crosslinking monomers, amine unsaturated monomers and isocyanate crosslinking agents;

[0029] 3) Add the monomer in step 2) dropwise to the reaction flask and stir for reaction, and keep stirring for 2 hours after the dropwise addition;

[0030] 4) Cool down to 80°C, add aminoalcohol compound;

[0031] 5) Add deionized water dropwise within 1 hour. After the dropwise addition, stir and disperse for 2 hours to obtain a coating film-forming material.

Embodiment 1

[0032] Example 1: Coalescing agent: S-100 mineral spirits 4g, ethylene glycol butyl ether 4g; Acrylic ester monomer: methyl methacrylate 32.2%; Self-crosslinking monomer: acetoacetoxy ethyl methacrylate Ester 1.8g; amine unsaturated monomer: acrylamide 8g; isocyanate crosslinking agent: toluene diisocyanate 1.5g; alcohol amino compound: dimethylethanolamine 1.4g, the rest is deionized water.

Embodiment 2

[0033] Embodiment 2: Coalescing aid: S-100 solvent naphtha 4g, propylene glycol butyl ether 4g; Acrylic monomer: methyl methacrylate 33%; Self-crosslinking monomer: acetoacetoxy ethyl methacrylate 1.2 g; amine unsaturated monomer: 6 g of methylol acrylamide; isocyanate crosslinking agent: 1.5 g of toluene diisocyanate; alcohol amino compound: 2.4 g of triethanolamine, and the rest is deionized water.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap