Locking fastener with tenon

A technology of fasteners and bolts, which is applied in the field of locking fasteners with mortise, which can solve the problems of object through-holes and round-head square-neck bolts being prone to deflection, round-head square-neck bolts are prone to offset, and matching accuracy is not high. problems, to achieve uniform force, increase the scope of application, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

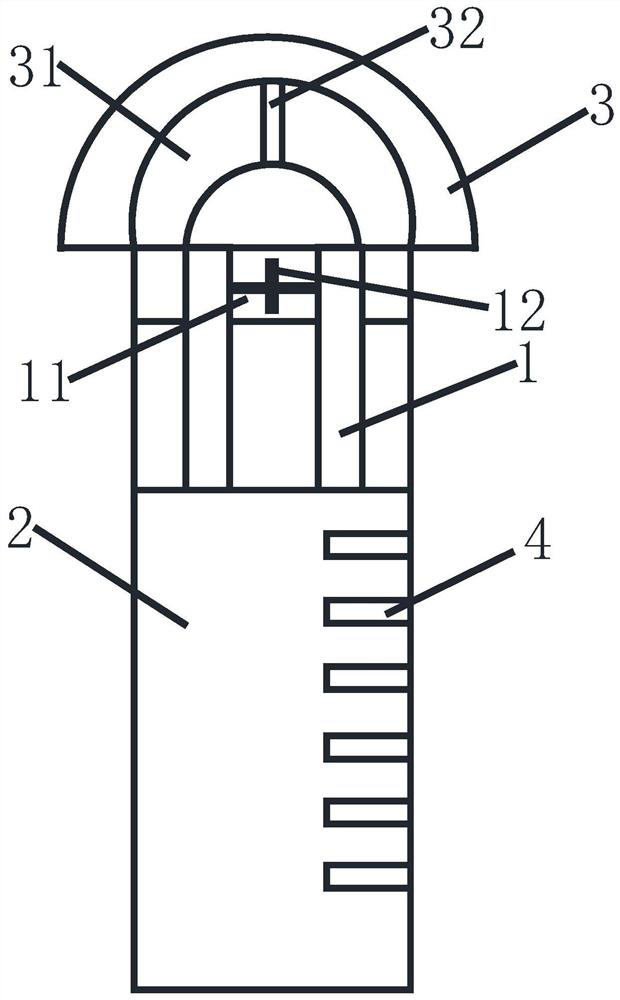

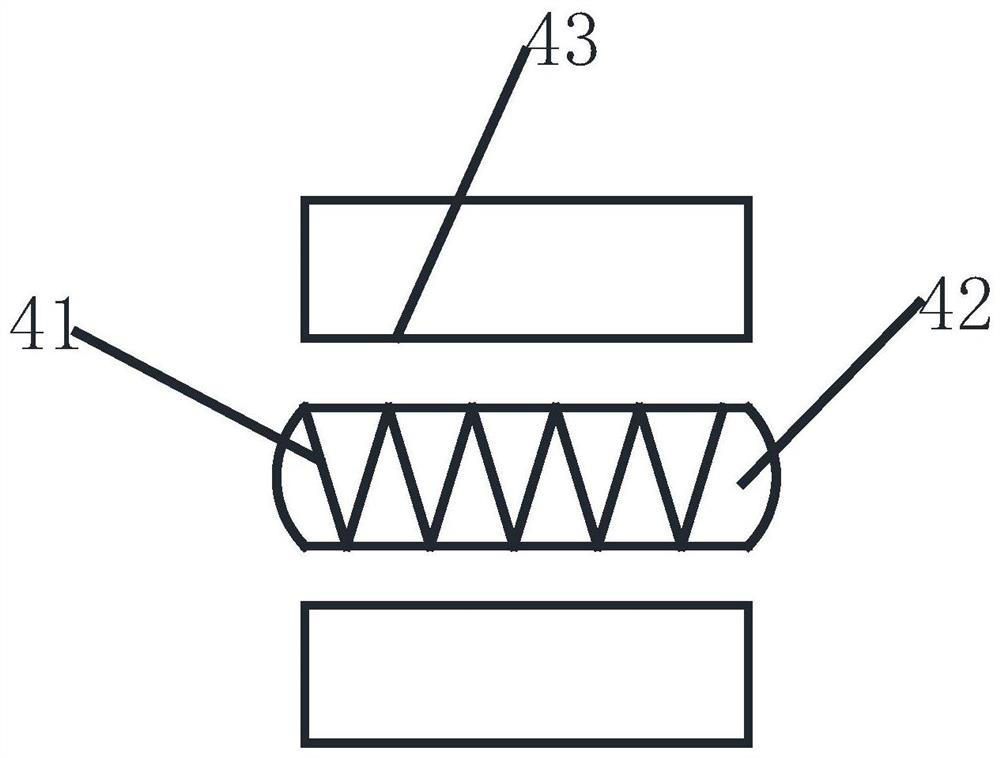

[0019] refer to figure 1 , figure 2 , the present invention provides a locking fastener with mortise, comprising a bolt head 3 with a hemispherical round head end and a screw rod 2 located at one end of the bolt head 3 coaxial with the bolt head 3, the bolt head 3 A square neck 1 is provided at the junction with the screw rod 2, and an inner screw hole is provided at the center of the other end of the bolt head 3, and the stem portion of the bolt head 3, square neck 1 and screw rod 2 is cold Upsetting into an integrated structure, the bolt head 3 is wrapped with a shock absorbing sleeve, and a chamber is provided at the center of the bolt head 3, and a shock absorbing bag 31 is placed in the chamber, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap