Design method of near-junction cooling structure of ultrahigh heat flow radio frequency microsystem

A technology for cooling structures and design methods, applied in design optimization/simulation, constraint-based CAD, special data processing applications, etc. Reliability, optimal design results, and the effect of reducing design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

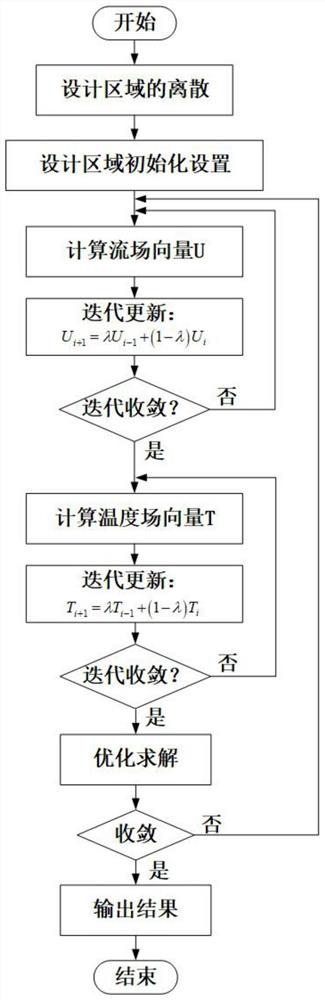

[0052] refer to figure 1 , a method for designing a near-junction cooling structure of an ultra-high heat flow radio frequency microsystem, comprising the following steps:

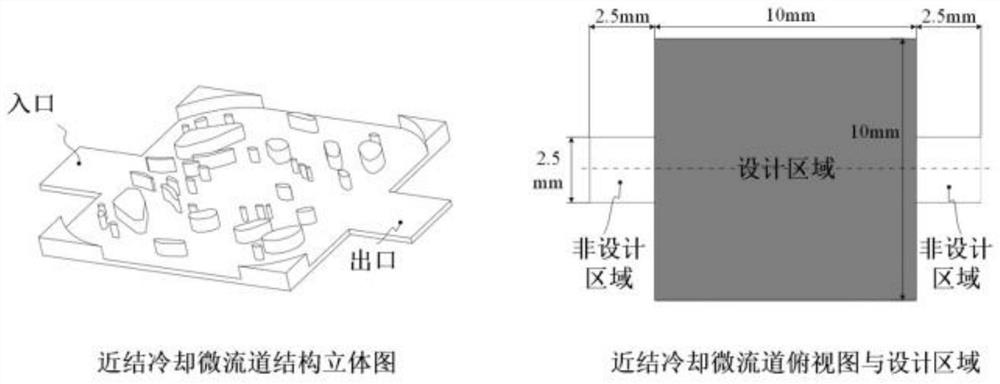

[0053] 1) Discretization of the design area: such as figure 2 As shown, the near-junction cooling micro-channel is symmetrical up and down along the horizontal center line, the size of the middle channel area is 10(mm)×10(mm), and the left and right sides of the channel area are 2.5(mm)× 2.5 (mm) entrance and exit area, the design area only includes the middle flow channel area; the design area is discretized into 120×240 finite element elements, and the discretized design area includes 120 rows and 240 columns;

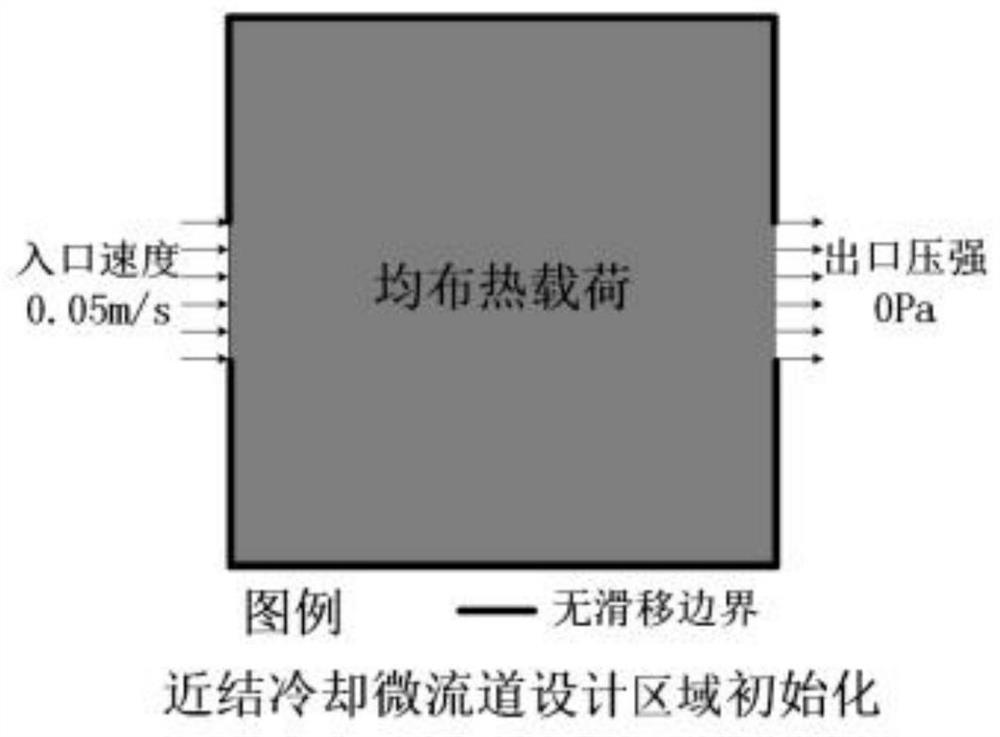

[0054] 2) Design area initialization settings:

[0055] 2.1) The use of the Stokes flow model: set the fluid flow state in the design area as laminar flow, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap