Construction elevator

A technology of construction elevators and power mechanisms, applied in the field of elevators, can solve problems such as leakage, personal safety threats to staff, submerged control cabinets, etc., to achieve the effects of ensuring personal safety, avoiding adverse effects, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

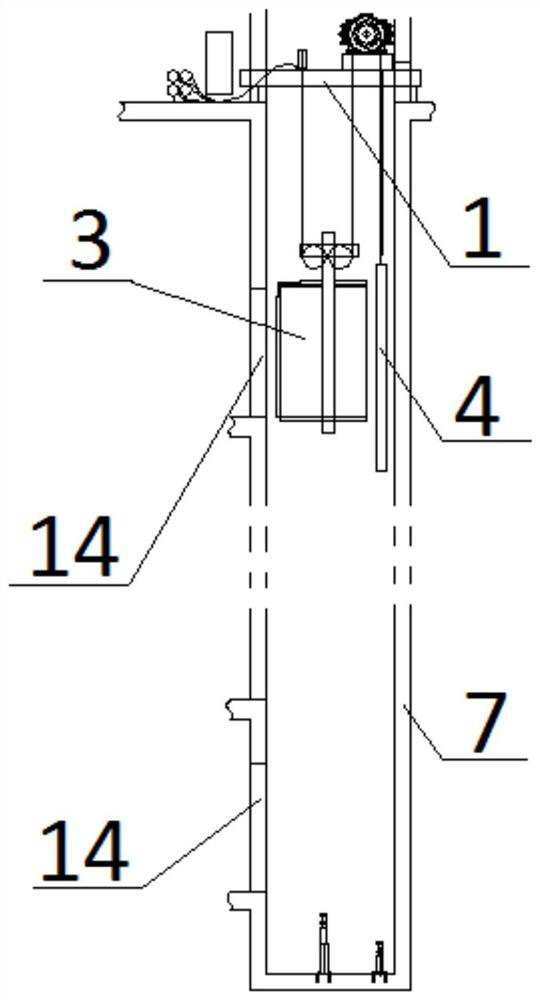

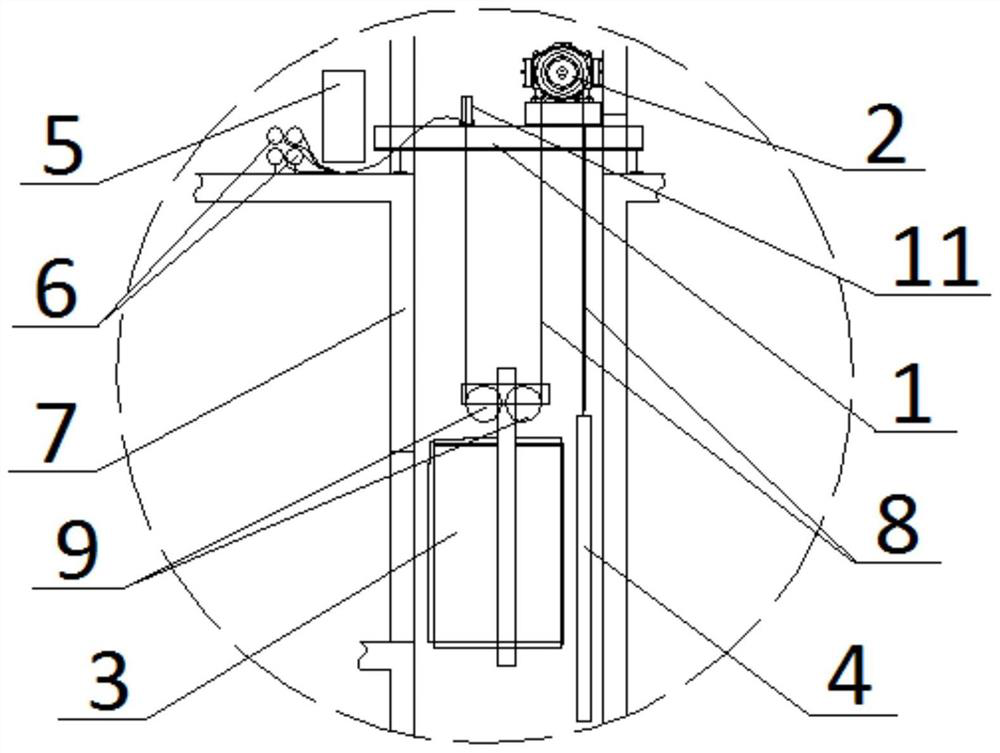

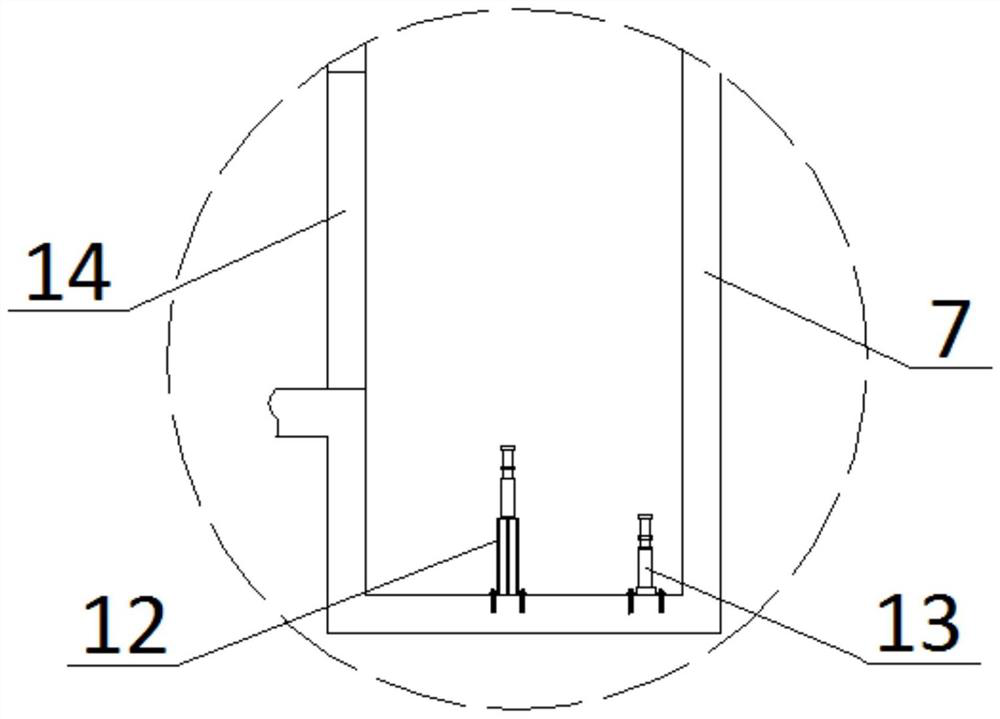

[0019] figure 1 Schematically shows the structure of a construction hoist according to an embodiment of the present invention, figure 2 shown figure 1 A part of a construction hoist in the structure; image 3 shown figure 1 Another part of a construction hoist structure. Such as Figure 1-3 As shown, the construction hoist is installed in the construction shaft, and mainly includes structures such as sky beam 1, power mechanism 2, cage 3, counterweight 4, and control cabinet 5. Sky beam 1 is installed on shaft 7, and power mechanism 2 is installed on On the sky beam 1 , the cage 3 and the counterweight 4 are both arranged inside the hoistway 7 below the sky beam 1 , and are also connected with the power mechanism 2 through a wire rope 8 . Wherein, the power mechanism 2 can be selected as a traction machine or an electric hoist or the like. In addition, t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap