Amorphous alloy transformer with circular iron core and short-circuit-resistant structure, and manufacturing method thereof

A technology of amorphous alloy and manufacturing method, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor core, transformer/inductor components, etc., can solve the impact of production efficiency and production cost, and weak resistance to short-circuit force , increase manufacturing costs and other issues, to achieve the effect of improving production efficiency, reducing production time, and reducing material weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

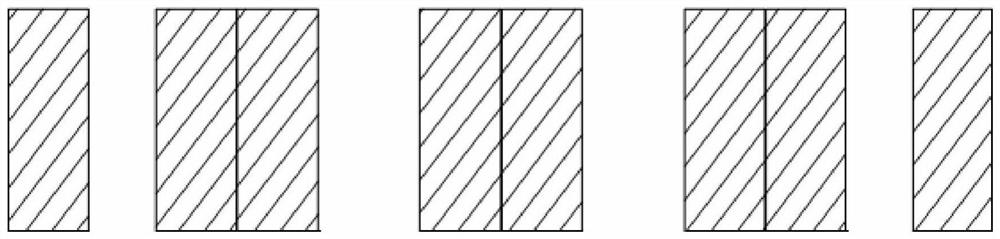

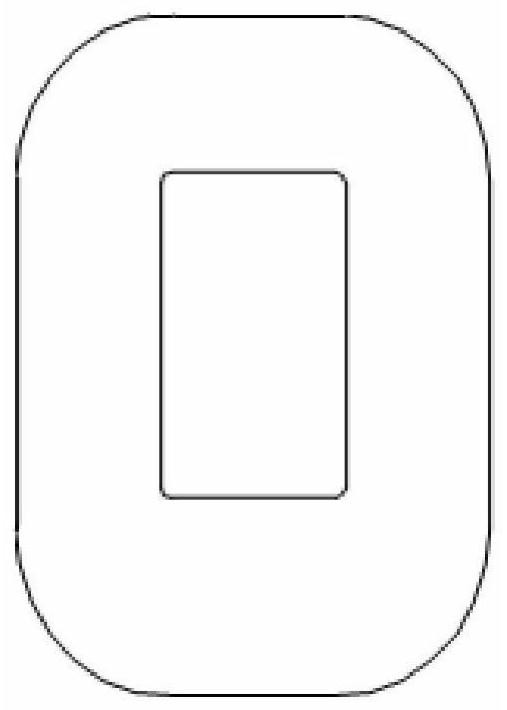

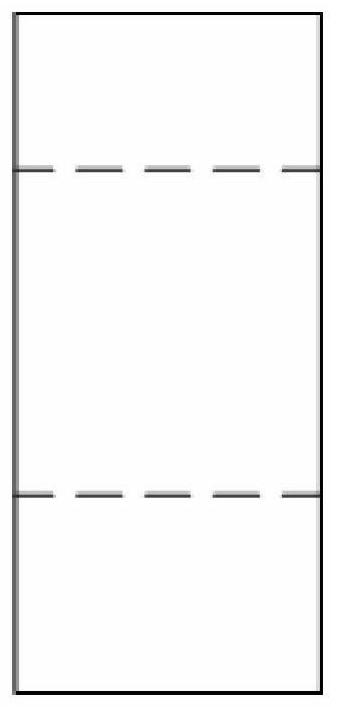

[0060] Such as Figure 5 , 6A As shown in ~6C, the present invention is an amorphous alloy transformer with a circular iron core anti-short circuit structure. The iron core adopts a three-phase five-column structure. Among the three main columns, each iron core column has four structures with the same structure and a cross-section of The circle formed by the combination of right-angle stepped single cores, and the side columns on both sides are semicircular formed by the combination of two right-angled stepped single cores with the same structure; the three main columns of the three-phase five-column structure are installed The coil forms the device body, and an upper clamping part and a lower clamping part are respectively installed on the body and the lower ends of the device.

[0061] Each right-angle stepped shape is made of rectangular amorphous

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap