Stripping machine for recycling scrapped cable

A stripping machine and cable technology, applied in the direction of electronic waste recycling, recycling technology, circuits, etc., can solve the problems of inconvenient replacement, inability to apply cable sheaths, and easily damaged cutting knives, and achieve the effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034]Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

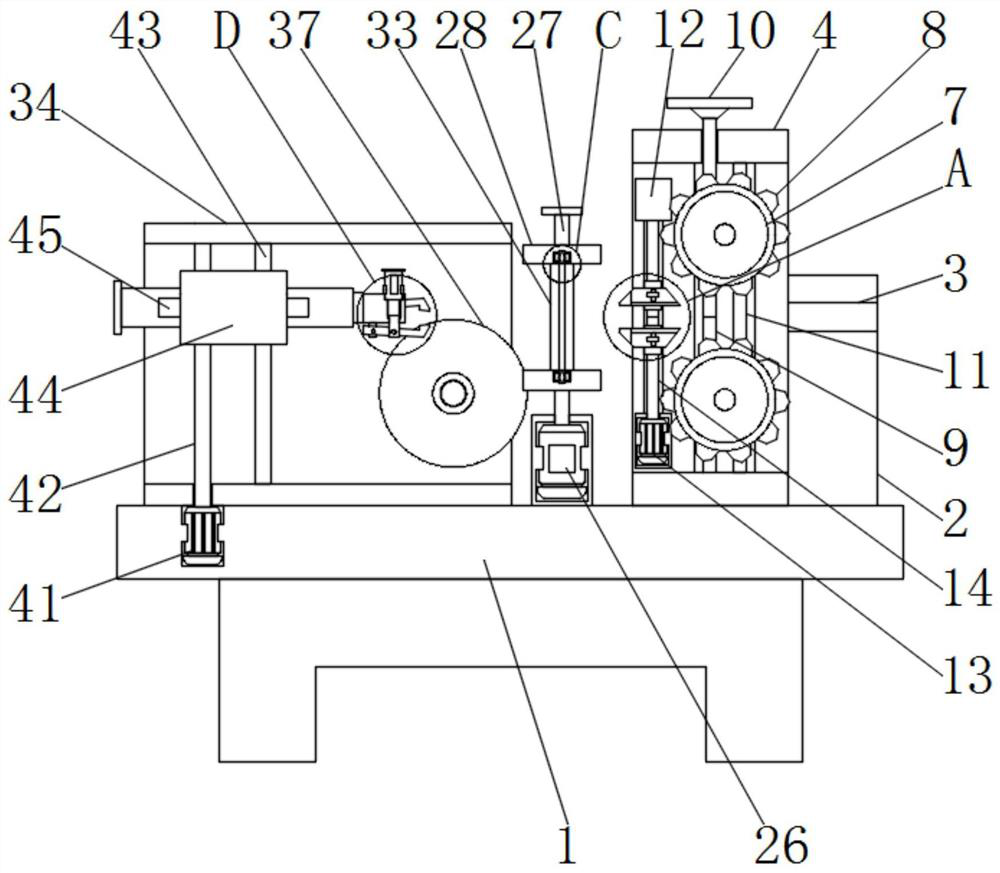

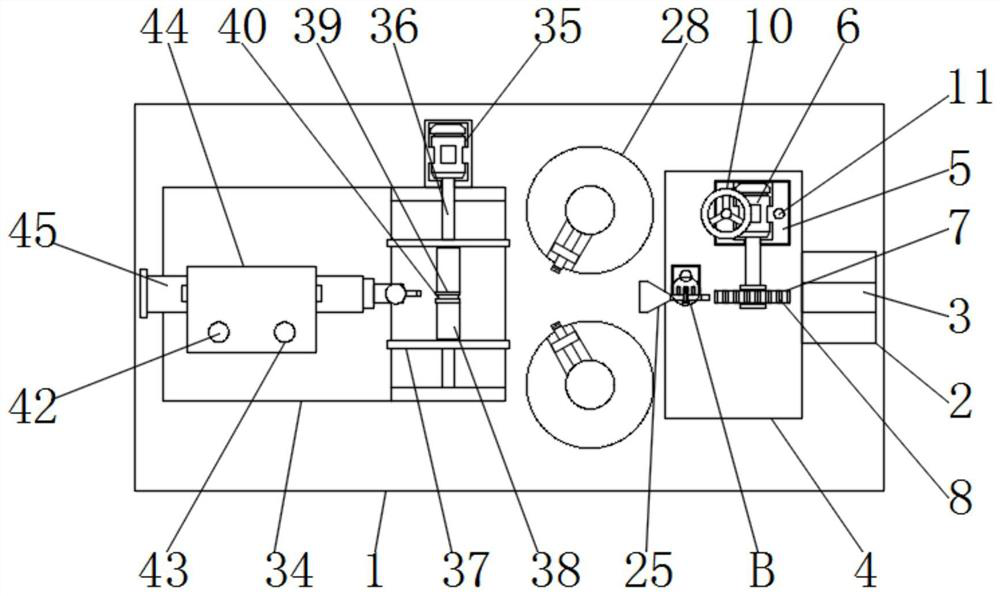

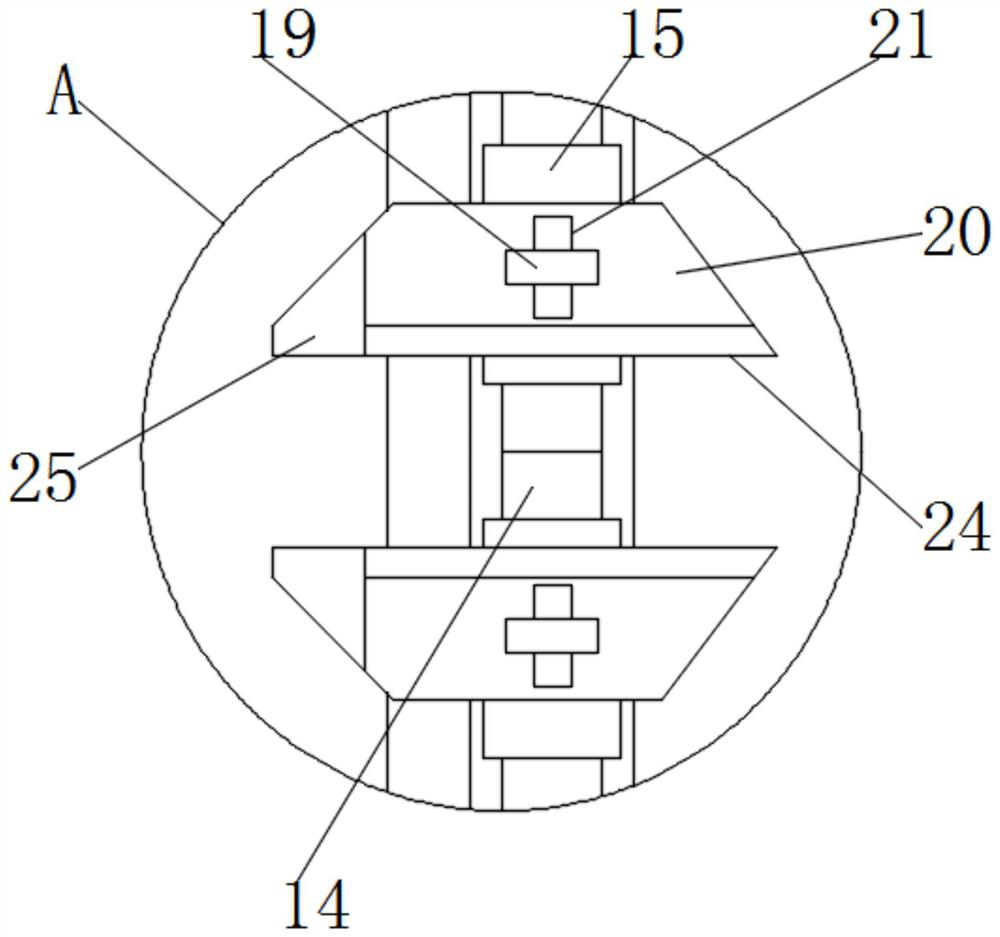

[0035] See Figure 1-6 The present invention provides a technical solution: A cable scrap recovered by stripping machine, comprising a table, a first fixing table 2, the feed tank 3, the second fixing table 4, a first moving block 5, a first motor 6 turntable 7, 8 teeth pressed, the first bi-directional threaded rod 9, the control valve 10, a first guide bar 11, a first fixing block 12, a second motor 13, the second bidirectional threaded rod 14, a second moving block 15, thread groo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap