Rice impurity removing device

A technology of rice and No. 1, applied in the field of rice-related processing, can solve the problems of easily blocking the machine, affecting the processing environment of the workshop, increasing the workload of workers, etc., and achieving the effect of increasing the effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The following embodiments will be described in detail in conjunction with the accompanying drawings of the present invention, the description or the drawings, similar or identical parts the same reference numerals, and in practical applications, the components of the shape, thickness, or may be expanded or reduced height. The exemplified embodiment of the present invention are intended to illustrate various embodiments of the present invention is not intended to limit the scope of the present invention. Any modifications known or apparent changes made to the invention without departing from the spirit and scope of the invention.

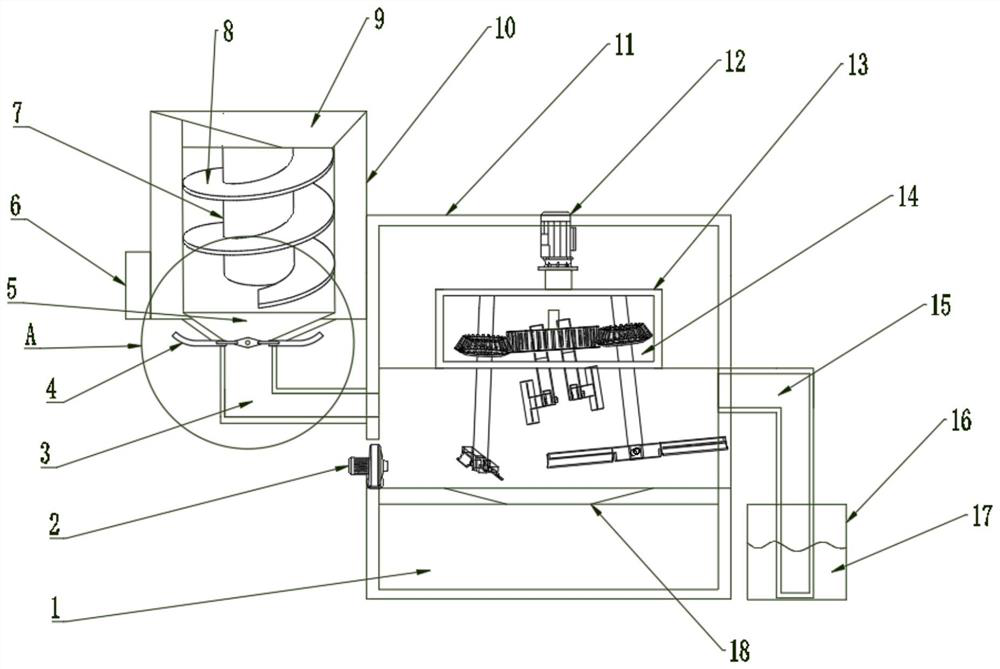

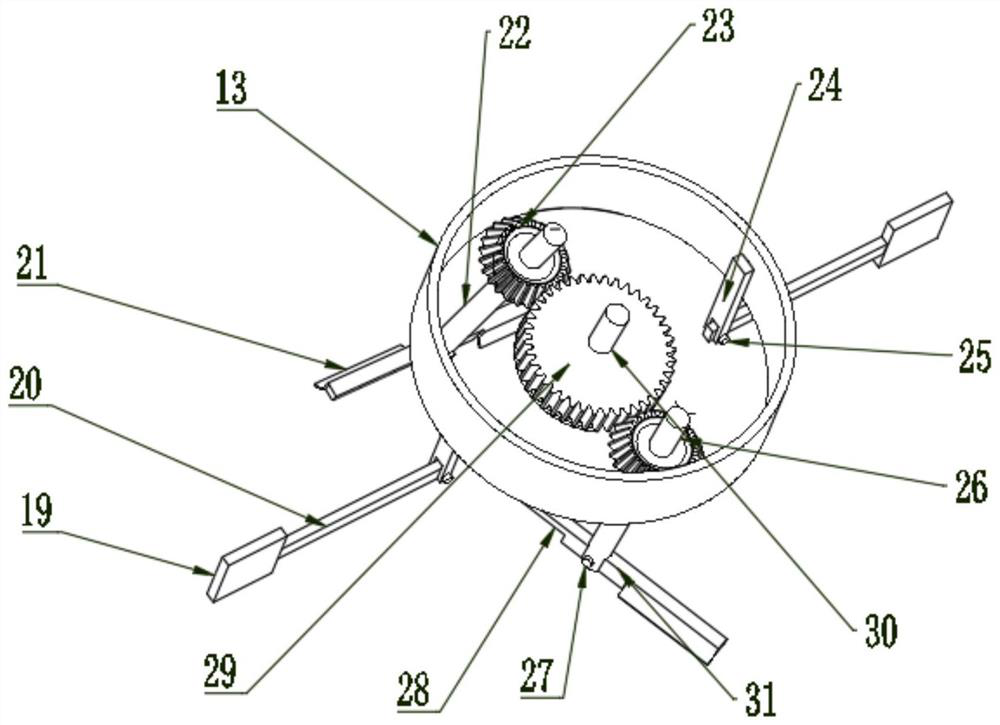

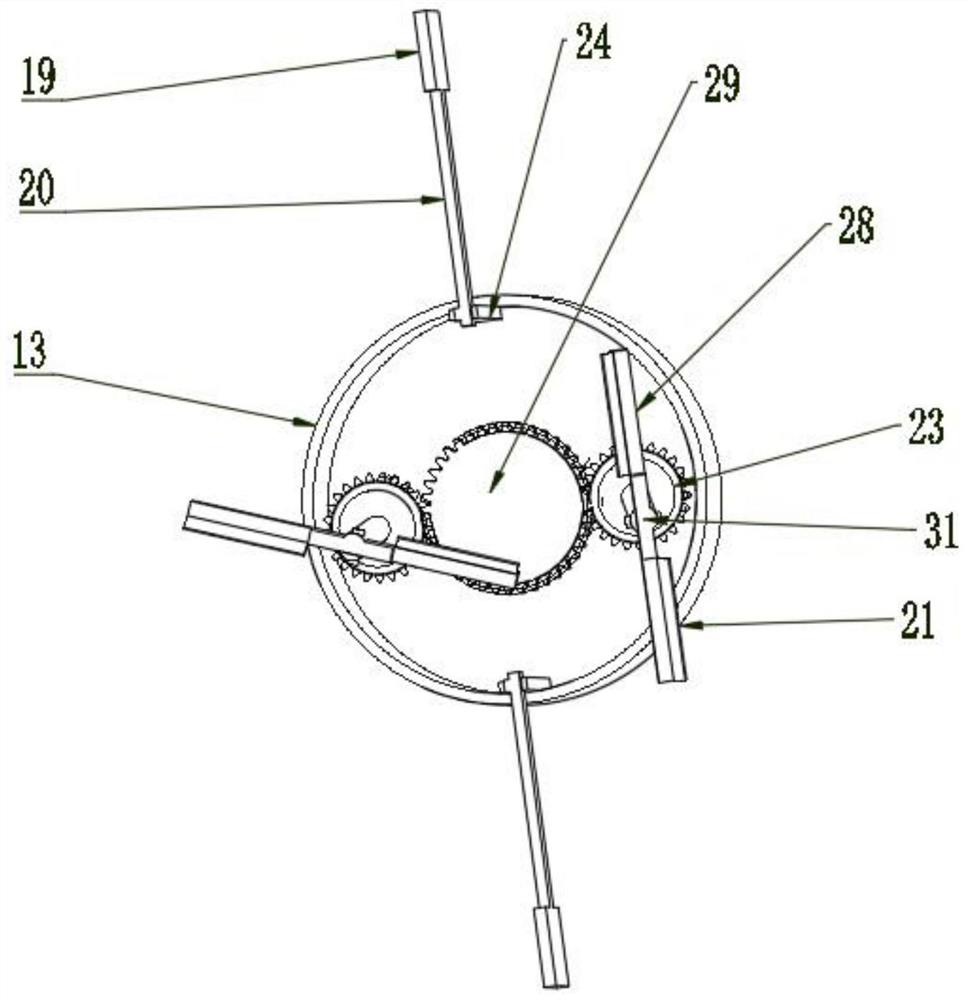

[0024] See Figure 1 ~ 3 , For example, an impurity rice apparatus In one embodiment of the present invention, comprising a dust box 11; 11 of the dust box 14 is provided with stirring means and collection means, the stirring mechanism 14 comprises a sheet 21 was stirred One , link 22 II, II shaft 26, the connecting element 27 II, II stir plate 28, fo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap