Magnesium calcium silicate heat preservation integrated plate and processing method thereof

A calcium magnesium silicate and processing method technology, applied in covering/lining, construction, building construction, etc., can solve the problems of simple structure of insulation board, inconvenient installation of insulation board, prolonging construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

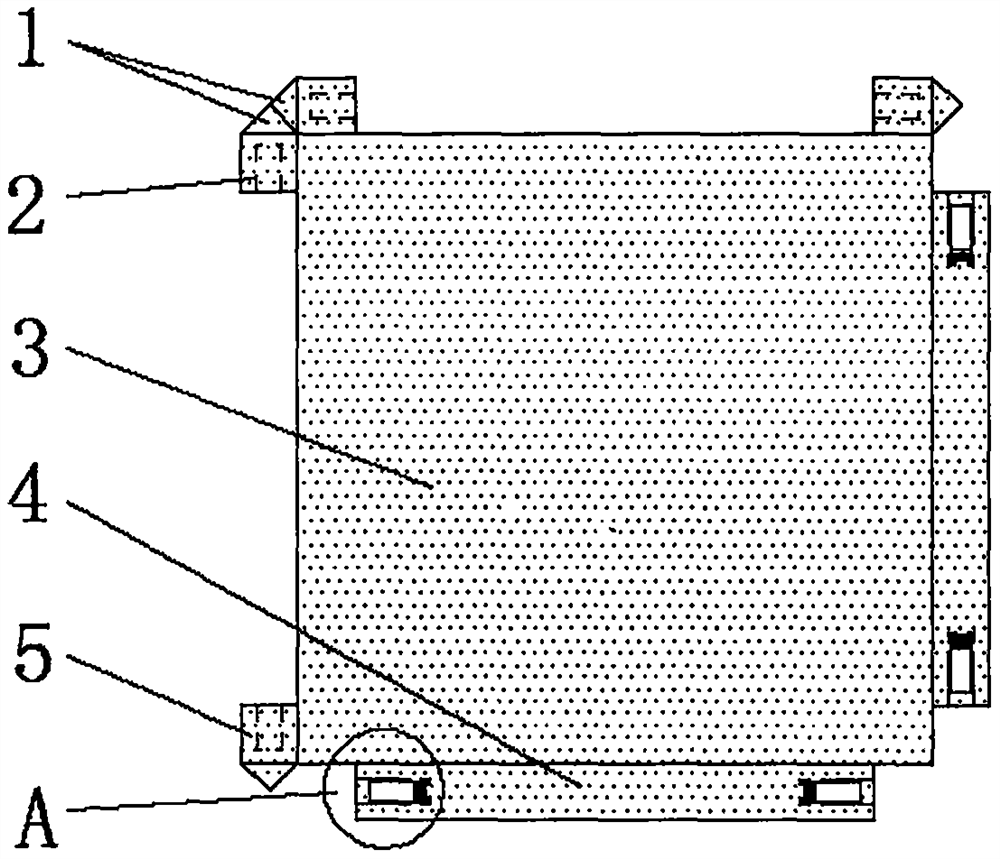

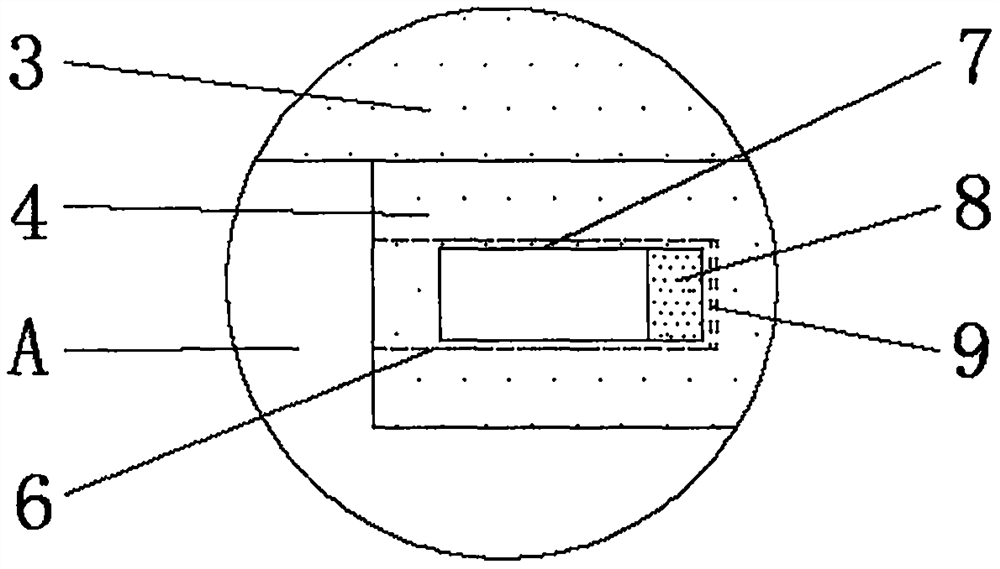

[0031] Such as figure 1 The calcium-magnesium silicate thermal insulation integrated board shown includes a main board body 3, the material of the main board body 3 is calcium magnesium silicate, and each of the four sides of the main board body 3 is connected with corresponding A middle connector 4 and two end connectors 5 are adapted, the sum of the lengths of the middle connector 4 and the end connectors 5 is equal to the side length of the corresponding side of the main body 3, and the two ends of the middle connector 4 The end faces are respectively aligned with the opposite faces of the two end connectors 5, such as figure 2 As shown, the two ends of the middle connector 4 are provided with accommodating grooves 6 parallel to its length direction, and the accommodating groove 6 is provided with an insertion shaft 9 parallel to its length direction. Both ends of the front of the connecting piece 4 are respectively provided with strip-shaped openings 7 parallel to the inser

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] In this example, if Image 6 As shown, the strip-shaped opening 7 penetrates to the end of the corresponding side of the middle connecting piece 4 . Such arrangement facilitates the installation of the pulling bar 8 and the plug-in shaft 9 fixed together, thereby simplifying the processing steps of the middle connecting piece 4 .

[0040] The processing method of the above-mentioned calcium magnesium silicate thermal insulation integrated board includes the following steps:

[0041] Firstly, calcium magnesium silicate material is used to prepare the integrated motherboard body 3, middle connector 4 and end connector 5; accommodating groove 6, and open a bar-shaped opening 7; then prepare the accessories fixed together by the plug-in shaft 9 and the pulling bar 8; finally insert the accessories into the corresponding accommodating groove 6, and make the pulling bar 8 Located in the strip opening 7, the

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is:

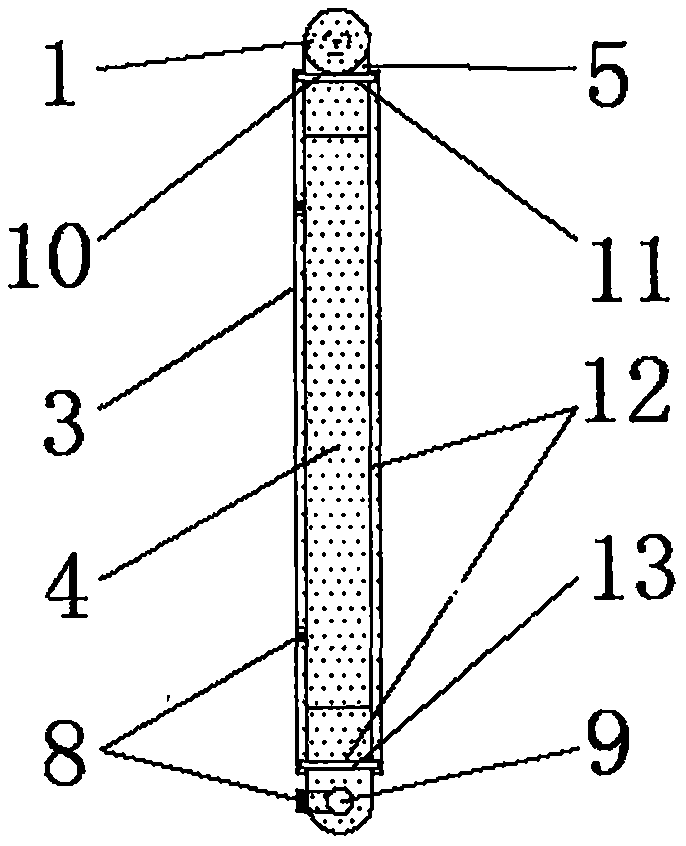

[0045] In this example, if image 3 , Figure 4 and Figure 5 As shown, the middle connector 4 and the end connector 5 are respectively slidingly connected to the main body 3, and the side of the main body 3 connected to the end connector 5 is provided with a first sliding groove 11 penetrating through the corresponding two ends. The side of the end connector 5 connected to the main body 3 is provided with a first connecting thin plate 10 slidingly connected to the first chute 11; the side of the main body 3 connected to the middle connector 4 is provided with two corresponding two The second chute 12 at the end, the side of the middle connecting piece 4 connected to the main body 3 is provided with a second connecting thin plate 13 slidably connected with the second chute 12 . The middle connecting piece 4 and the end connecting piece 5 are respectively slidingly connected with the main body 3, so that the m

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap