Honing tool magazine

A tool magazine and honing technology, used in honing machine tools, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as increased downtime, non-continuous operation of production lines, increased production costs, etc., and achieves low cost and replacement. The effect of good knife reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

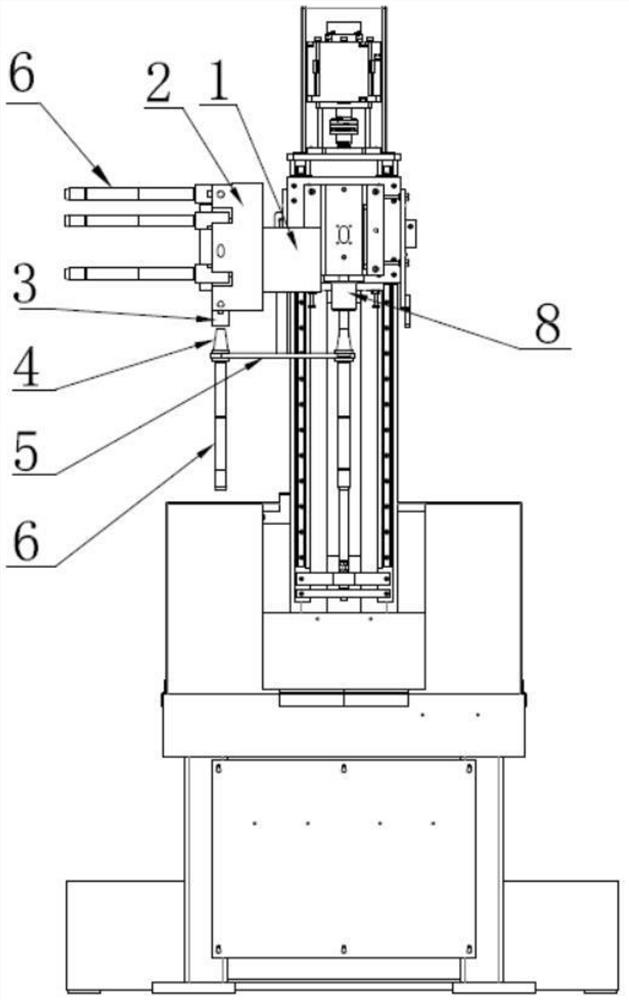

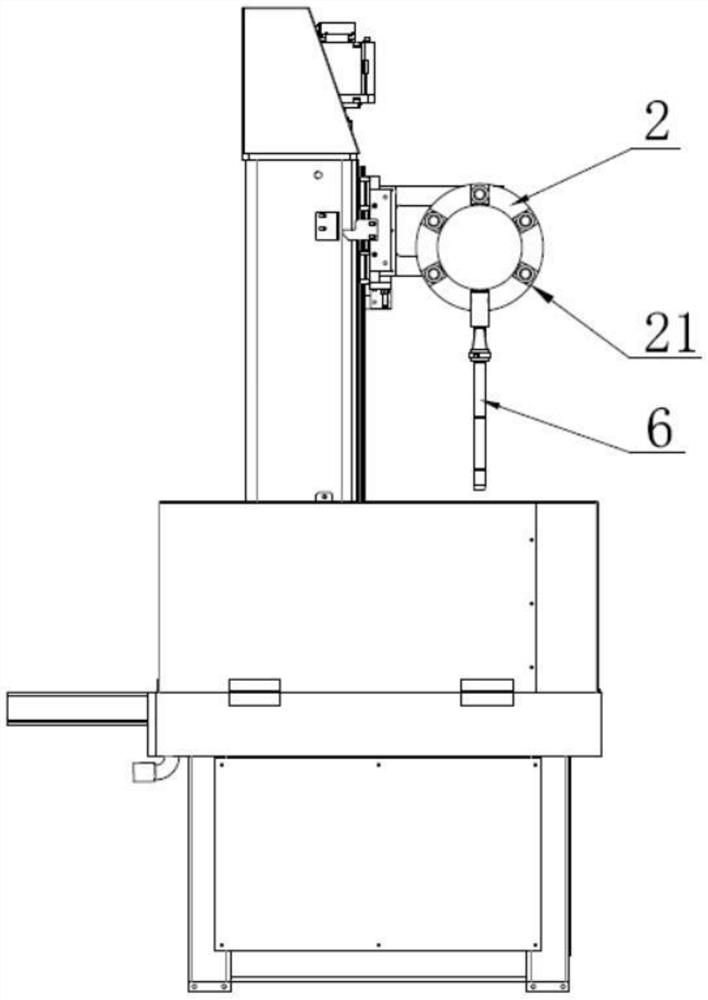

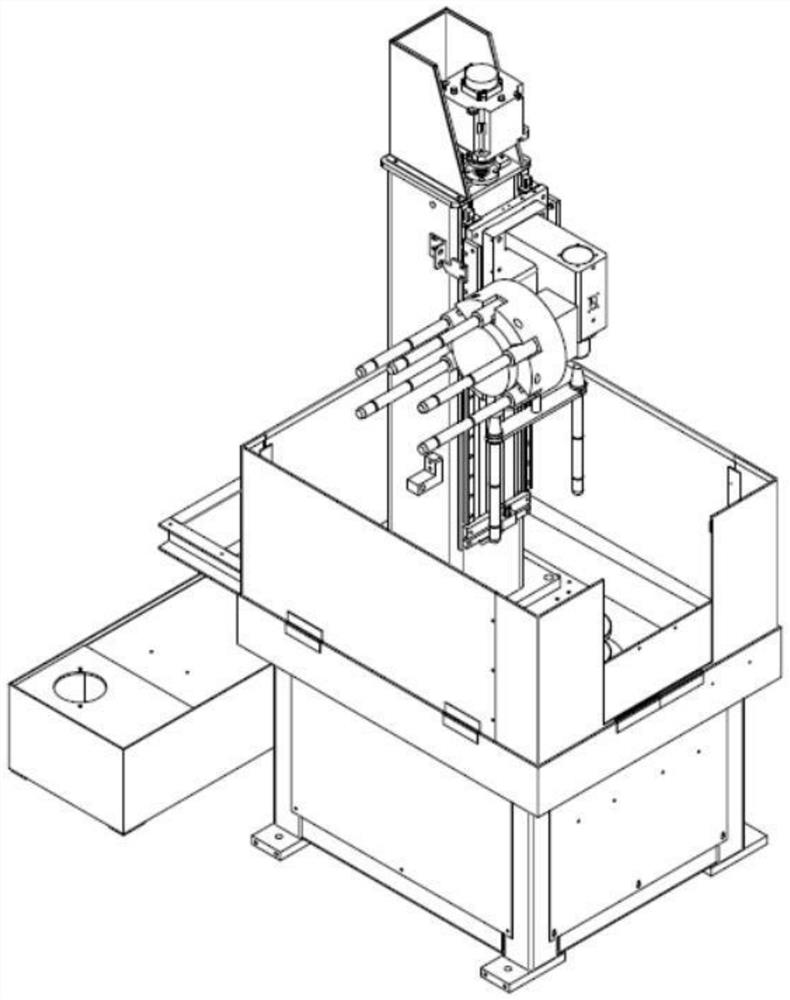

[0023] like Figure 1-Figure 4 It shows a specific embodiment of a honing tool magazine: including a driving device 1, a tool magazine 2, a double-arm rotary manipulator 5 and a honing tool 6;

[0024] The knife magazine 2 is circular, and a driving device 1 is connected to one side of the knife magazine 2, and 6 or 8 knife cylinder installation slots 21 are arranged on the other side of the knife magazine 2, and the A knife barrel 3 is installed in the knife barrel installation slot 21, an end of a handle 4 is inserted in the knife barrel 3, and a honing tool 6 is installed on the other end of the knife handle 4; It is movably connected in the knife barrel installation slot 21 , and the knife barrel installation slot 21 extends to the outer wall of the knife magazine 2 .

[0025] A double-armed rotary manipulator 5 is connected to the lower end of the driving device 1 through a connecting rod, and two ends of the double-armed rotary manipulator 5 are provided with arc-shaped cl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap