Chip FPC and manufacturing method thereof

A manufacturing method and chip technology, applied in the use/removal method of circuit masks, printed circuit manufacturing, printed circuits, etc., can solve the problems of increased production costs, waste of resources or energy, etc., to reduce weight and save production costs , to avoid the effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033]The present invention will be further described below with reference to the drawings and embodiments.

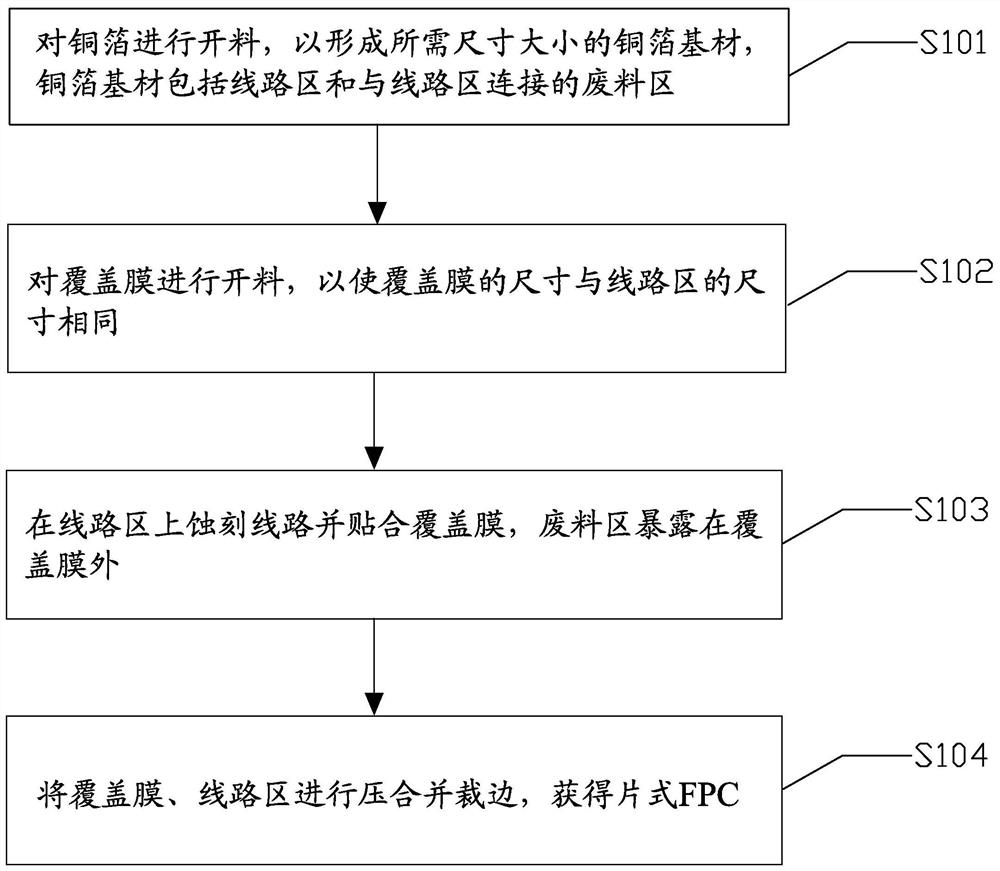

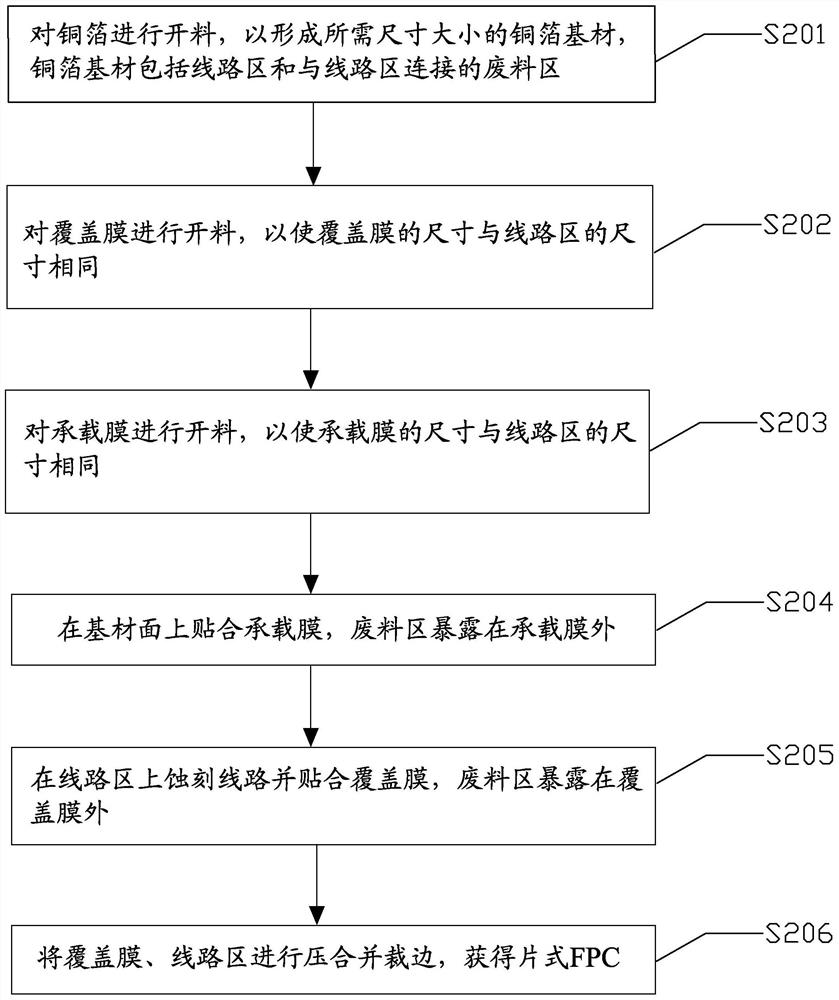

[0034]figure 1 It is a schematic flow chart of the manufacturing method of the chip FPC according to the first embodiment of the present invention. It should be noted that if there are substantially the same results, the method of the present invention does notfigure 1 The sequence of the processes shown is limited. Such asfigure 1 As shown, the method includes:

[0035]Step S101: cutting the copper foil to form a copper foil base material of a required size. The copper foil base material includes a circuit area and a waste area connected to the circuit area.

[0036]In step S101, the circuit area is used to place circuits and functional tool holes, and the waste area is used for subsequent positioning and operation. There is no need to place circuits and functional tool holes. Therefore, the waste area does not need to be covered with a film for protection and does not need to be attac

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap