Biological organic fertilizer and production equipment of biological organic fertilizer

A technology for organic fertilizers and production equipment, applied in the field of organic fertilizers, can solve problems such as environmental pollution, poor crushing effect, and difficulty in controlling the degree of fermentation, and achieve the effects of solving environmental pollution, improving crushing effect, and improving crop stress resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment relates to a kind of bio-organic chemical fertilizer, calculated by weight, comprising: 50 parts of crop straws, 20 parts of biological enzymes, 50 parts of plant stems and leaves, 50 parts of plant ash, 20 parts of humus, 10 parts of ammonium sulfate, and sulfuric acid Potassium 10 parts;

[0044] Wherein, the material component of humic agent comprises by weight: 4 parts of Aspergillus niger, 3 parts of Trichoderma viride, 2 parts of Trichoderma pseudocorning, 1 part of fermenting cellulophage, 3 parts of Bacillus amyloliquefaciens, succinic acid silk 2 parts of bacteria, and 10 parts of chitosan.

[0045] Preferably, in this embodiment, Aspergillus niger is (Aspergillus niger) ATCC 6275;

[0046] Trichoderma viride is (Trichoderma viride) ATCC 9645;

[0047] Trichoderma koningiopsis (Trichoderma koningiopsis) CGMCC NO.8948;

[0048] Fermentation cellulophage is (Cytophaga fermentans) ATCC 19072;

[0049] Bacillus amyloliquefaciens is (Bacillus

Embodiment 2

[0058] The present embodiment relates to a kind of bio-organic chemical fertilizer, calculated by weight, comprising: 40 parts of crop straws, 15 parts of biological enzymes, 40 parts of plant stems and leaves, 40 parts of plant ash, 15 parts of humus, 10 parts of ammonium sulfate, and sulfuric acid Potassium 10 parts;

[0059] Wherein, the material components of the humic agent include 3 parts by weight of Aspergillus niger, 2.5 parts of Trichoderma viride, 2 parts of Trichoderma pseudocorning, 0.8 part of fermenting cellulophage, 3 parts of Bacillus amyloliquefaciens, succinic acid filamentous Bacillus 1.3 parts, and chitosan 8 parts.

[0060] Preferably, in this embodiment, Aspergillus niger is (Aspergillus niger) ATCC 6275;

[0061] Trichoderma viride is (Trichoderma viride) ATCC 9645;

[0062] Trichoderma koningiopsis (Trichoderma koningiopsis) CGMCC NO.8948;

[0063] Fermentation cellulophage is (Cytophaga fermentans) ATCC 19072;

[0064] Bacillus amyloliquefaciens is (

Embodiment 3

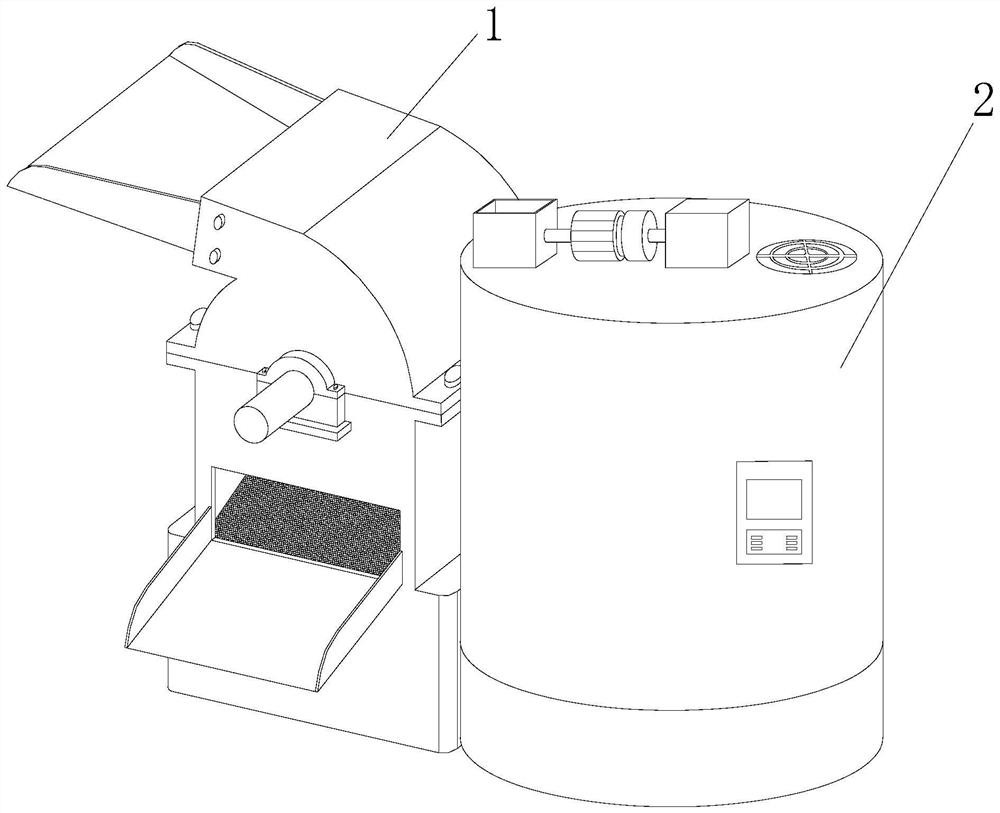

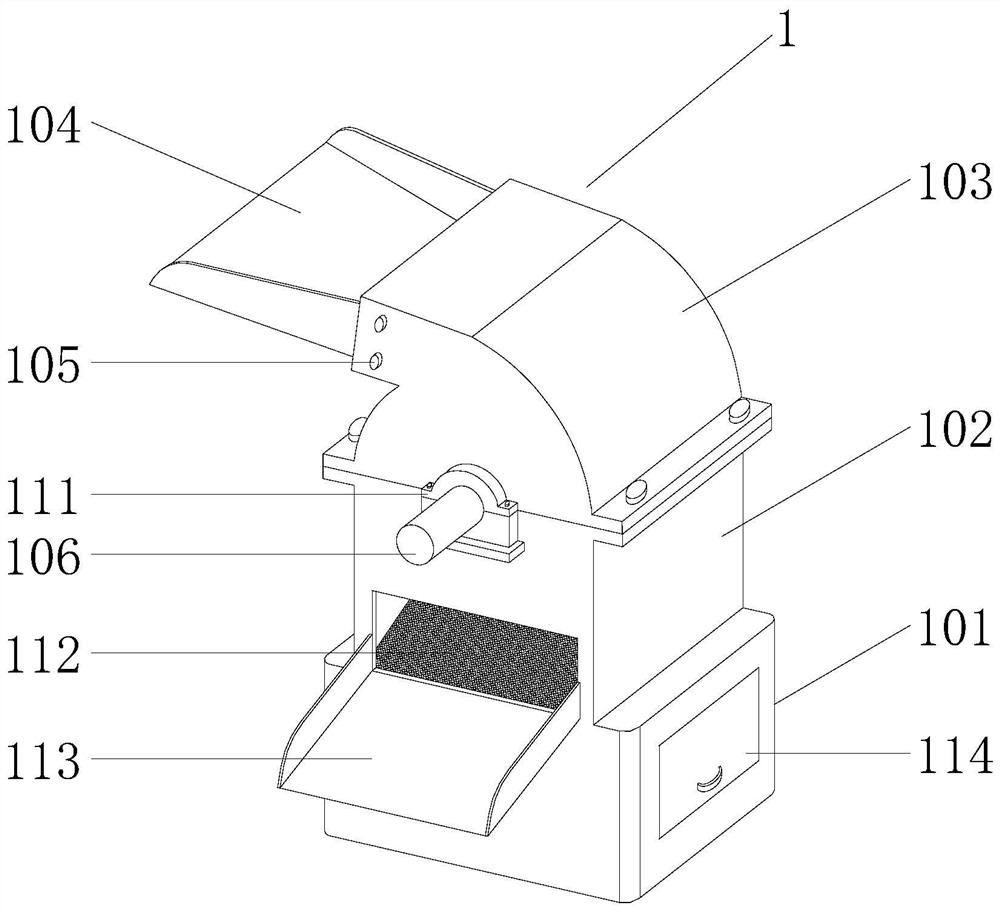

[0071] see Figure 1 to Figure 7 , the present invention also provides another embodiment, which relates to a production equipment for preparing the bio-organic fertilizer described in the above-mentioned embodiments, specifically, the production equipment of the bio-organic fertilizer includes a pulverizer 1 and a fermentation device 2 , each part of the bio-organic fertilizer production equipment will be further explained below:

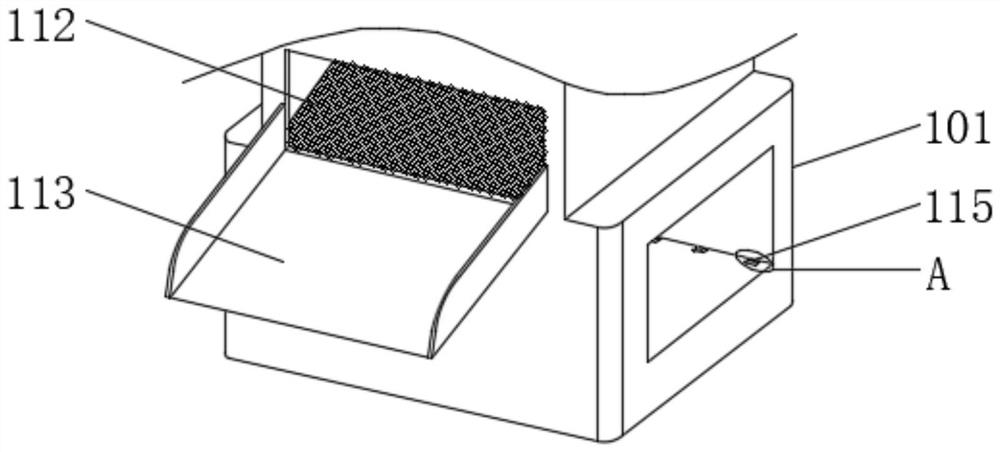

[0072] Wherein, the pulverizer 1 includes a base 101, a pulverizing chamber 102, a protective cover 103, a feeding table 104, a rotating shaft 106, a crushing roller 107, a crushing knife 108, a pulverizing motor, a sieve plate 112 and a collecting hopper 114;

[0073] The crushing chamber 102 is arranged on the base 101, and the crushing chamber 102 is provided with a crushing chamber. The upper end of the crushing chamber 102 is provided with an upper opening, and the side end of the crushing chamber 102 is provided with a side opening. The cavity

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap