Wear-resistant composite building template

A technology of building templates and composite materials, which is applied in construction, building components, building structures, etc., can solve the problems of low strength and rigidity, fast aging speed, and resistance to ultraviolet rays, and achieve low cost, slow aging speed, and guaranteed The effect of construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention discloses a wear-resistant composite material building formwork, which is described in more detail below:

[0035] The present invention is characterized in that the composite building formwork includes a base layer and a wear-resistant protective layer covering at least one surface of the base layer, and the base layer includes the following components by mass: unsaturated resin matrix 30-50 0.1-0.3 parts of graphene nano-chips, 10-20 parts of glass fibers, and 40-60 parts of hard fillers.

[0036] The following is a further description of the technical solution of the present invention, but the following examples are only preferred implementation examples in the present invention rather than limiting the present invention.

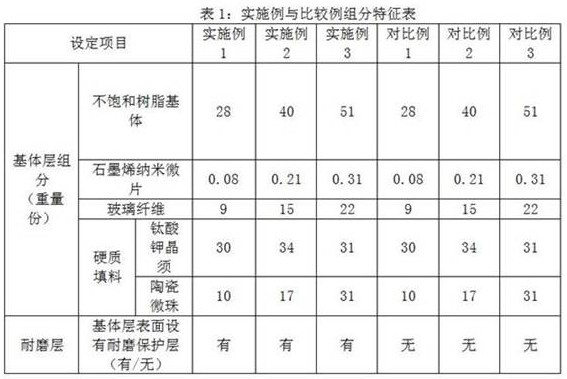

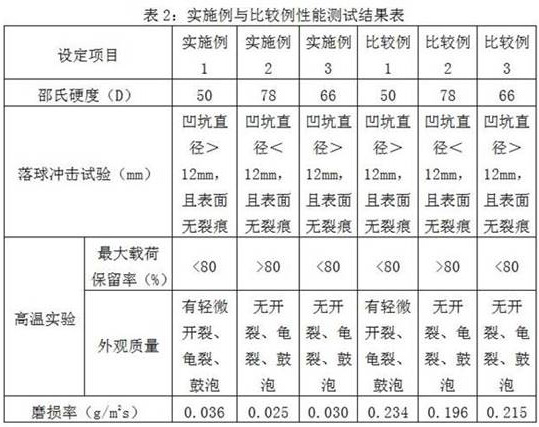

[0037] Set the base layer components of different mass parts, the presence or absence of the surface wear-resistant protective layer and the materials used, and obtain Examples 1-3 and Comparative Examples 1-3, as shown in Table 1:

[

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap