Lead-acid storage battery activator and preparation method thereof

A lead-acid battery and activator technology, used in lead-acid battery, lead-acid battery construction, secondary battery repair/maintenance, etc. Regeneration and repair effect, simple preparation method, and effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

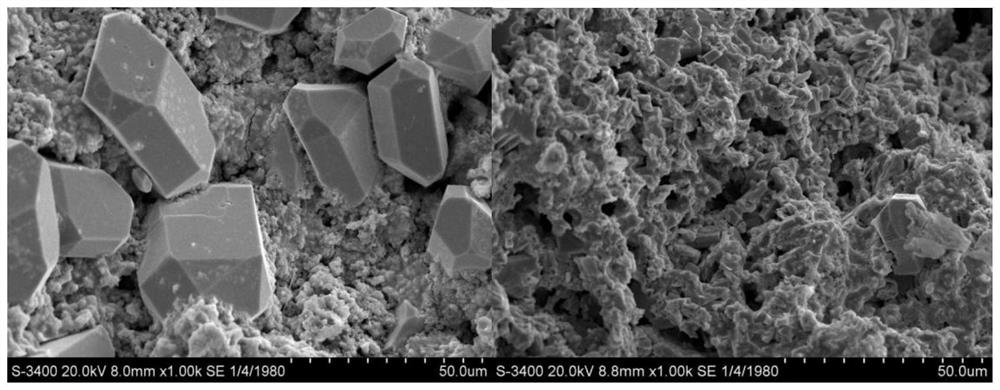

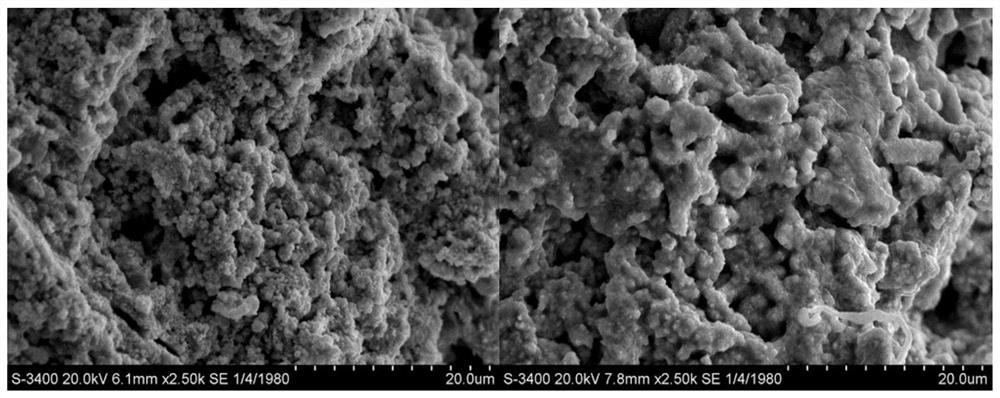

Image

Examples

Example Embodiment

[0032] Example 1

[0033] A lead-acid storage battery activator comprising:

[0034] Catalysts made of kaolin, magnesium-rich silicate ores, and gallium 8-hydroxyquinolate;

[0035] A mixture of highly conductive nano-carbon particles, polyacrylamide, sodium sulfate and potassium sulfate, the mass ratio of high-conductive nano-carbon particles, polyacrylamide, sodium sulfate and potassium sulfate is 1:0.05-0.1:1:1;

[0036] Deionized water with pH ≈7;

[0037] The percentage content of the catalyst is 0.01-0.05wt.%, and the percentage content of the mixture of high conductive nano-carbon particles, polyacrylamide, sodium sulfate and potassium sulfate is 0.05-0.1wt.%.

[0038] The preparation process of the catalyst is as follows: kaolin, magnesium-rich silicate ore and 8-hydroxyquinolate gallium are mixed according to a mass ratio of 1:10:0.1, and the mixed material is placed in a high-temperature kettle, and the temperature is set at 1350-1650 ℃, heated for 2 hours, cooled an

Example Embodiment

[0040] Example 2

[0041] The preparation method of lead-acid storage battery activator described in embodiment 1, it may further comprise the steps:

[0042] 1) Add 0.01-0.05 parts by mass of the catalyst to 100 parts by mass of deionized water and stir to form a transparent solution;

[0043] 2) Add the mixture of highly conductive nano-carbon particles, polyacrylamide, sodium sulfate and potassium sulfate to the transparent solution prepared in step 1) according to 0.05-0.1 parts by mass, and stir to form a translucent suspension to obtain lead acid Battery activator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap