High-temperature chemical vapor deposition system and equipment

A technology of vapor phase deposition and high-temperature chemistry, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of rapid heat dissipation of the heating barrel, poor insulation of the heating system, and inability to heat, etc., so as to achieve convenient reaction time and reaction temperature, easy to carry out efficiently, and the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021]In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

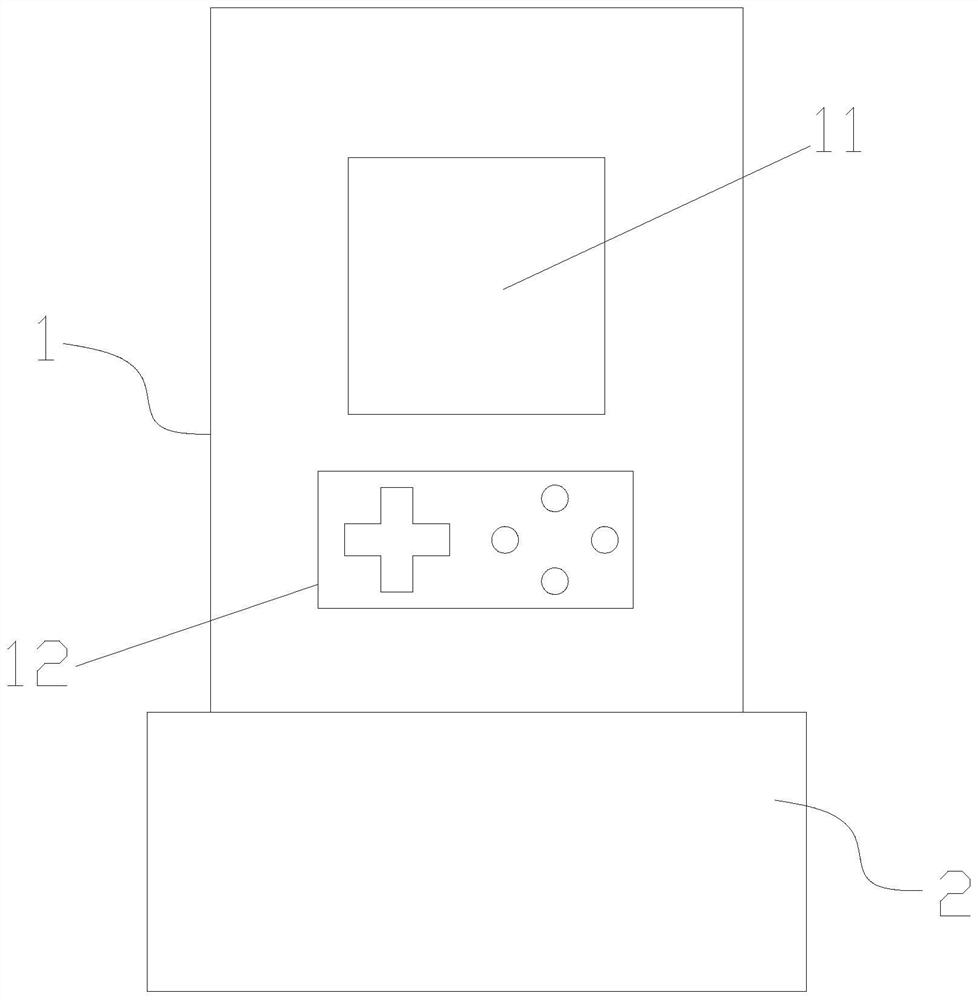

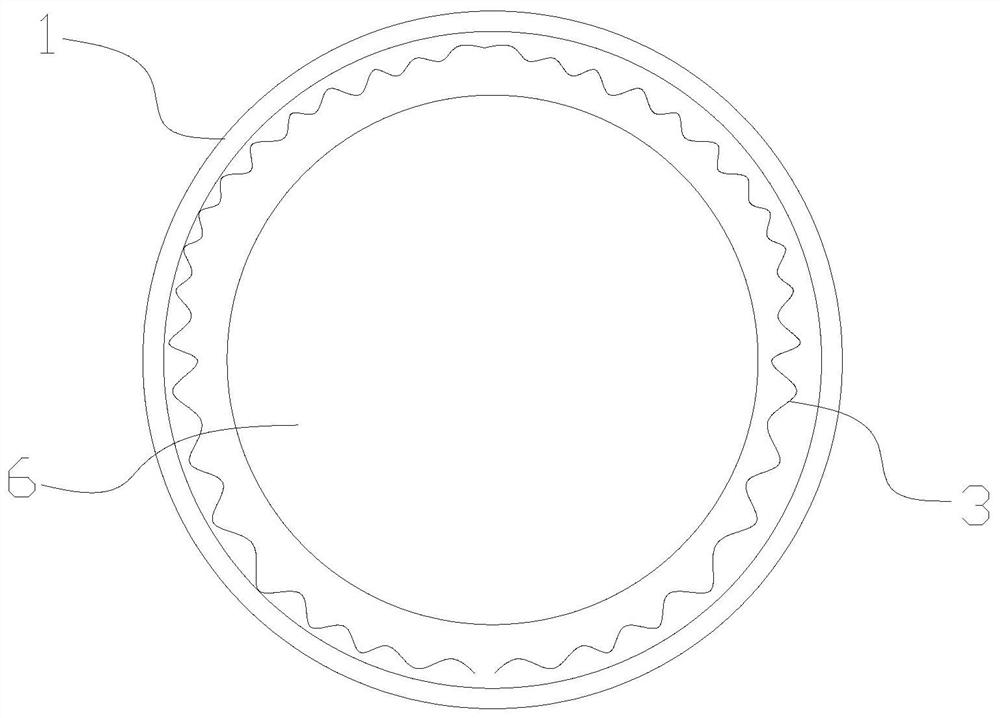

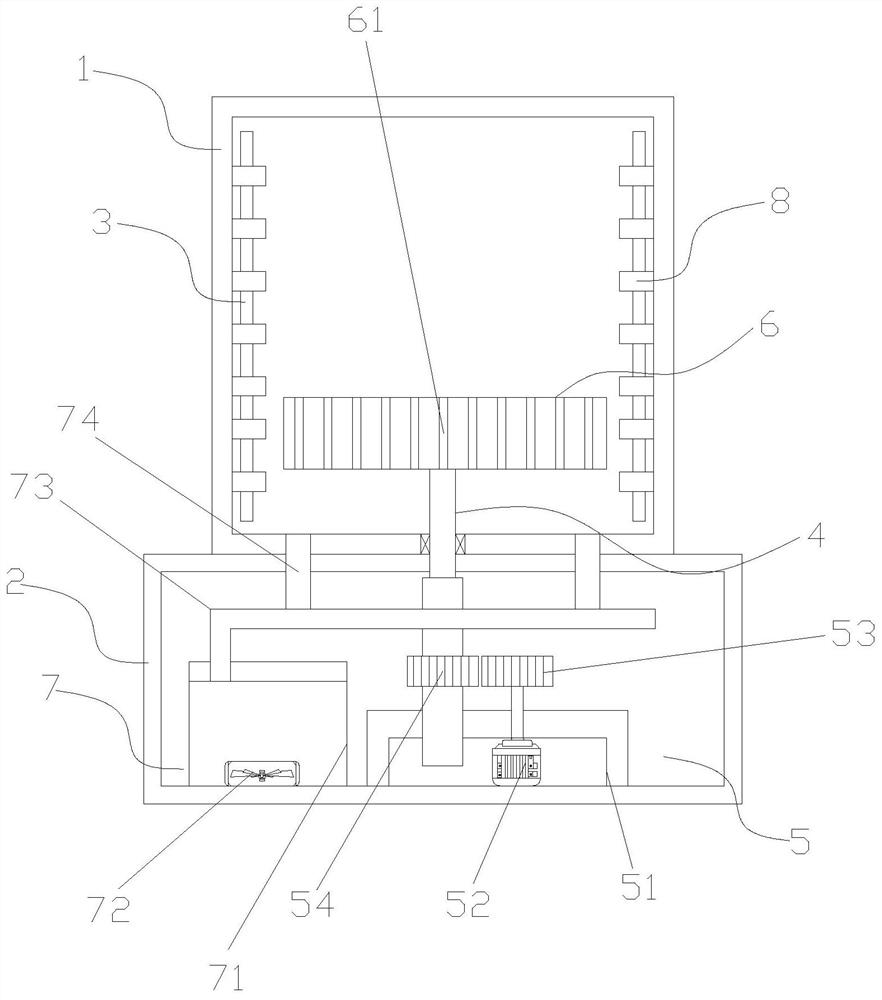

[0022]SeeFigure 1-4The present invention provides a technical solution: a high temperature chemical vapor deposition system includes an insulating heating tub 1 and a bottom case 2 fixed to a bottom portion thereof, an insulating heating tub 1 inner wall is provided with a heat generating member 3, and heat generating member 3 can generate 2000 Heating temperature above ° C;

[0023]The bottom case 2 is rotated and provided having a telescopic device 4 through the bottom of the insulating heating tub 1, and the bottom case 2 is also provided with a rotating device 5 that is rotatable with the rotation of the te

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap