Wafer film coating equipment

A coating film and equipment technology, applied in the field of wafer coating equipment, can solve the problems of floating, reducing the safety of wafer coating equipment, increasing the resistance of wafers, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

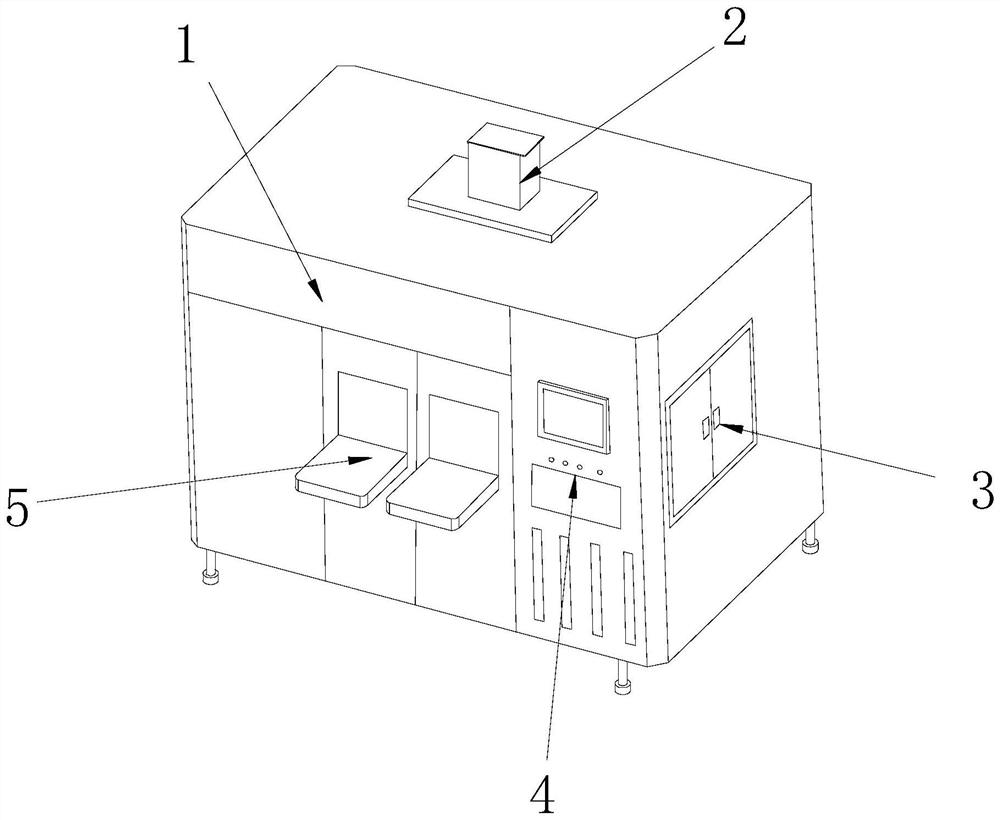

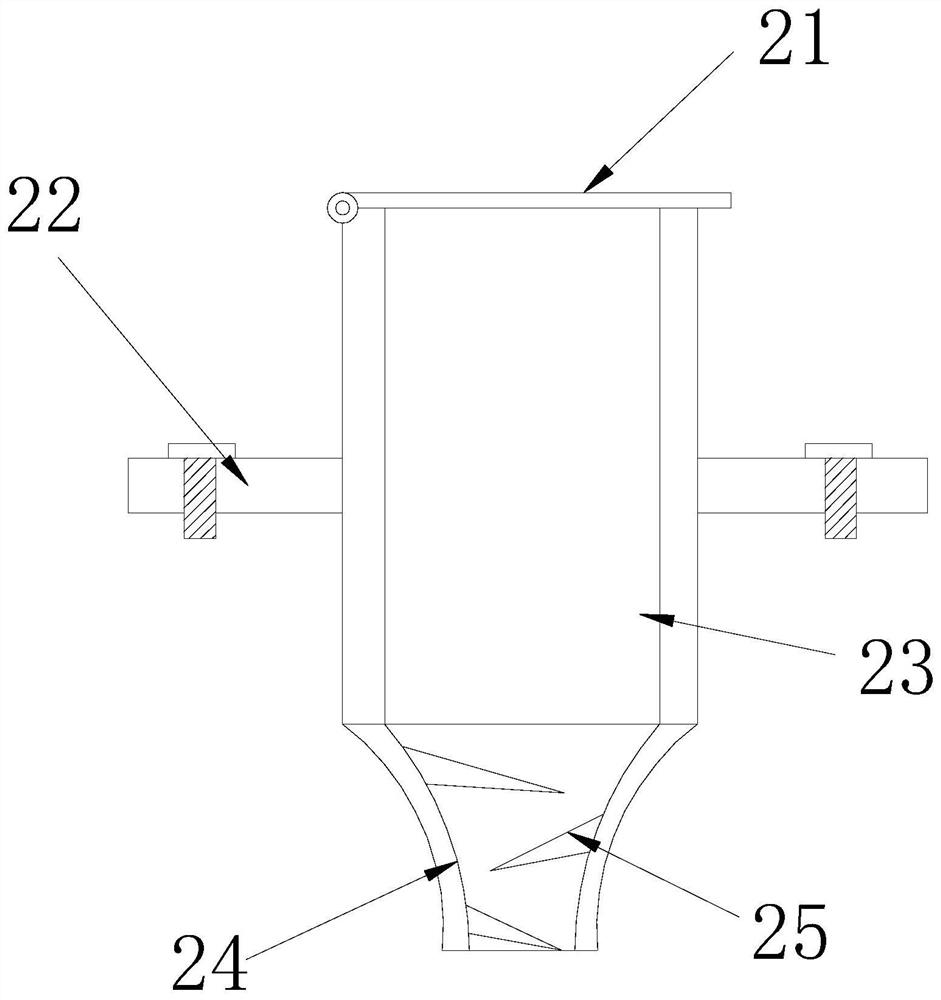

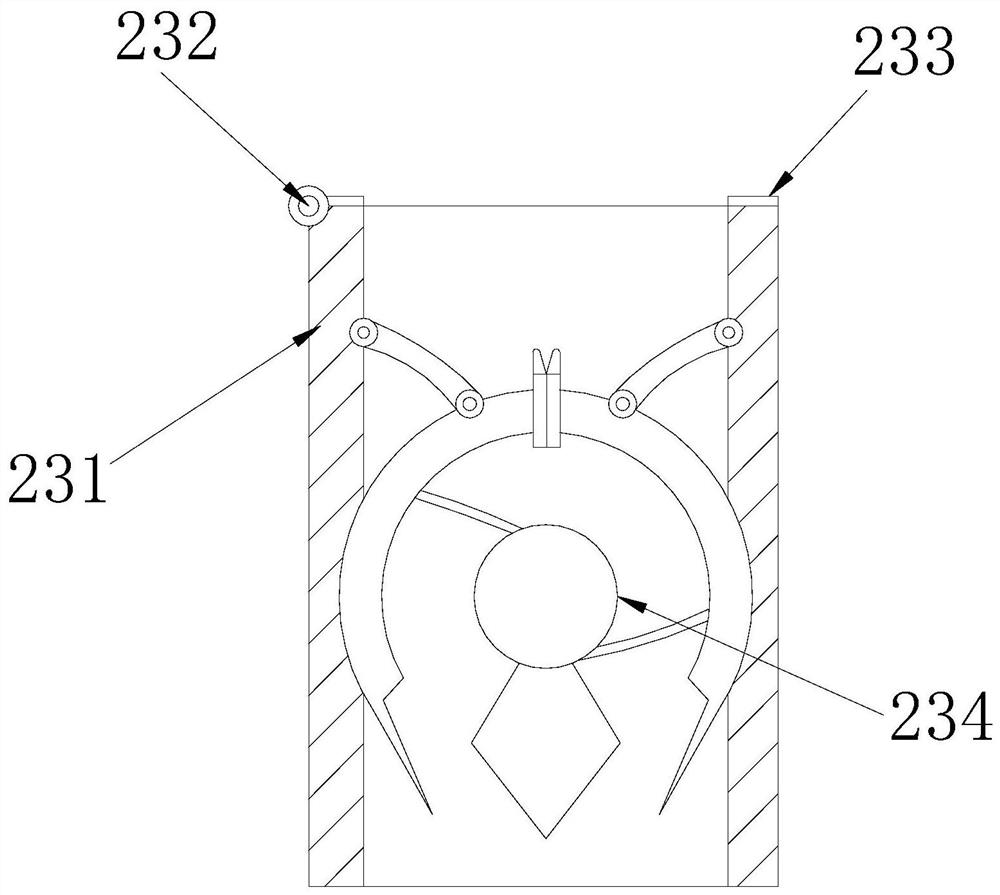

[0024] see Figure 1-Figure 5 , the specific embodiments of the present invention are as follows: a wafer coating equipment, its structure includes a body 1, a film liquid pipe 2, an inspection door 3, a control machine 4, and an input platform 5, and the film liquid pipe 2 is embedded on the top of the body 1 The two sides of the maintenance door 3 are hingedly connected to the right side of the body 1, the control machine 4 is embedded in the front of the body 1, the back of the input platform 5 is welded to the front of the body 1; the membrane liquid pipe 2 includes a sealing cover 21 , fixed plate 22, stay pipe 23, input pipe 24, blocking plate 25, the left side of the sealing cover 21 is hingedly connected with the top surface of the stay pipe 23, the top surface of the input pipe 24 is connected with the bottom surface of the stay pipe 23 and passes through Electric welding connection, one side of the blocking plate 25 is welded to the inner layer of the input pipe 24, the

Embodiment 2

[0030] see Figure 6-Figure 7 The specific embodiment of the present invention is as follows: the suction torsion wheel A15 includes a pressure handle B1, a chuck B2, a mounting ring B3, an elastic block B4, and an inner shaft B5, and the bottom end of the pressure handle B1 passes through the chuck B2 and the mounting ring The outer ring of B3 is movably engaged, the top of the elastic block B4 is embedded inside the installation ring B3, the bottom of the elastic block B4 is movably engaged with the outer ring of the inner shaft B5, and the elastic block B4 is provided with multiple, multiple elastic blocks The B4 gap is evenly embedded in the installation ring B3 in a ring shape, which is beneficial to increase the rebound speed and the pumping capacity.

[0031]Wherein, the elastic block B4 includes a soft ball B41, a twist frame B42, a twist ring B43, and a connector B44, the bottom of the soft ball B41 is movably engaged with the top of the twist frame B42, and the twist ri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap