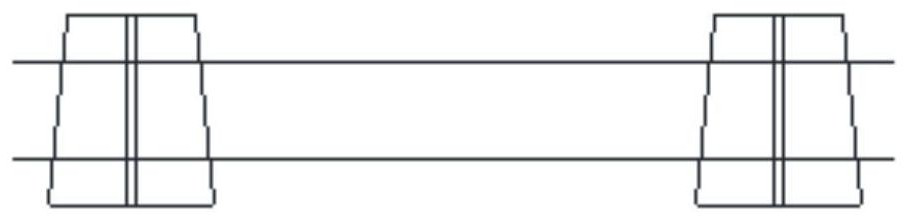

Prestressed steel-concrete combined box girder suspension splicing construction device

A technology of prestressed steel and construction devices, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of slow construction progress, slow construction progress, interrupted traffic, etc. for erecting supports, saving temporary construction facilities, low construction difficulty, The effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

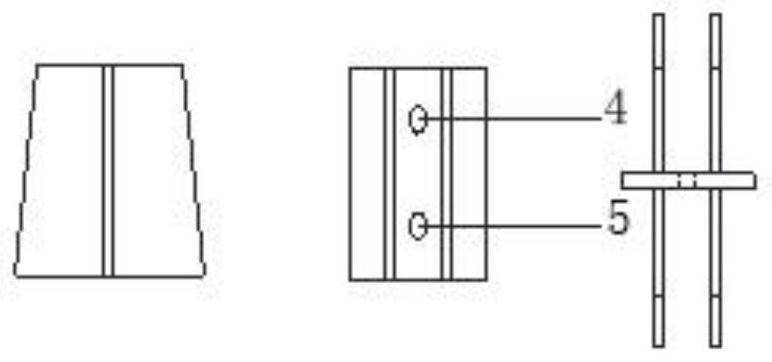

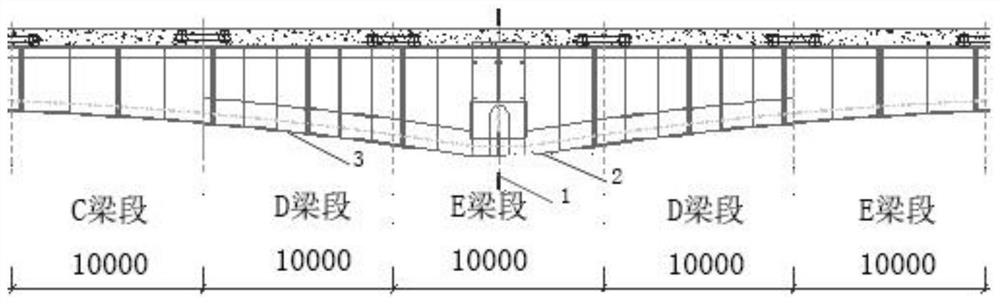

[0024] The specific implementation of the present invention is as follows: it includes the following hanging construction method: first, the first beam section 2 is installed on the support 1; Rolled rebar anchoring device; using finished rebar as the prestressed tendon of finished rebar to temporarily fix the second beam section 3 at both ends; welding and assembling two steel boxes so that the second beam section 3 and the first beam section 1 form a cantilever structure; Repeat the above process, and the cantilever can assemble the steel structure of the next segment.

[0025] The invention adopts fine-rolled threaded steel as the prestressed cantilever assembly construction device for the open steel box girder, which has the advantages of small construction difficulty; has the advantage of convenient cantilever construction without blocking traffic; saves construction temporary facilities and saves construction costs The advantages.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap