Clamping groove equipment for cutting and reinforcing outer side of solid wood cutting board

A cutting board and card slot technology, which is applied to the field of card slot equipment for cutting and reinforcing the outer side of a solid wood cutting board, can solve the problems of low work efficiency, cumbersome operation process, labor consumption and the like, and achieve the effect of improving work efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

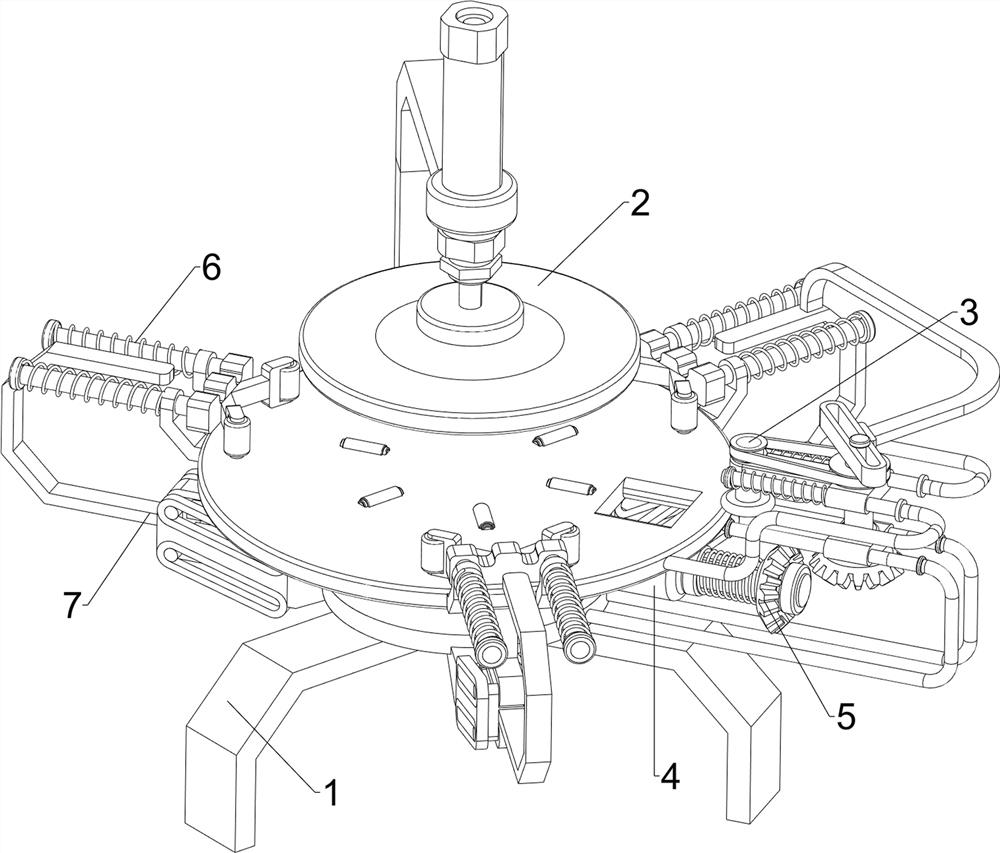

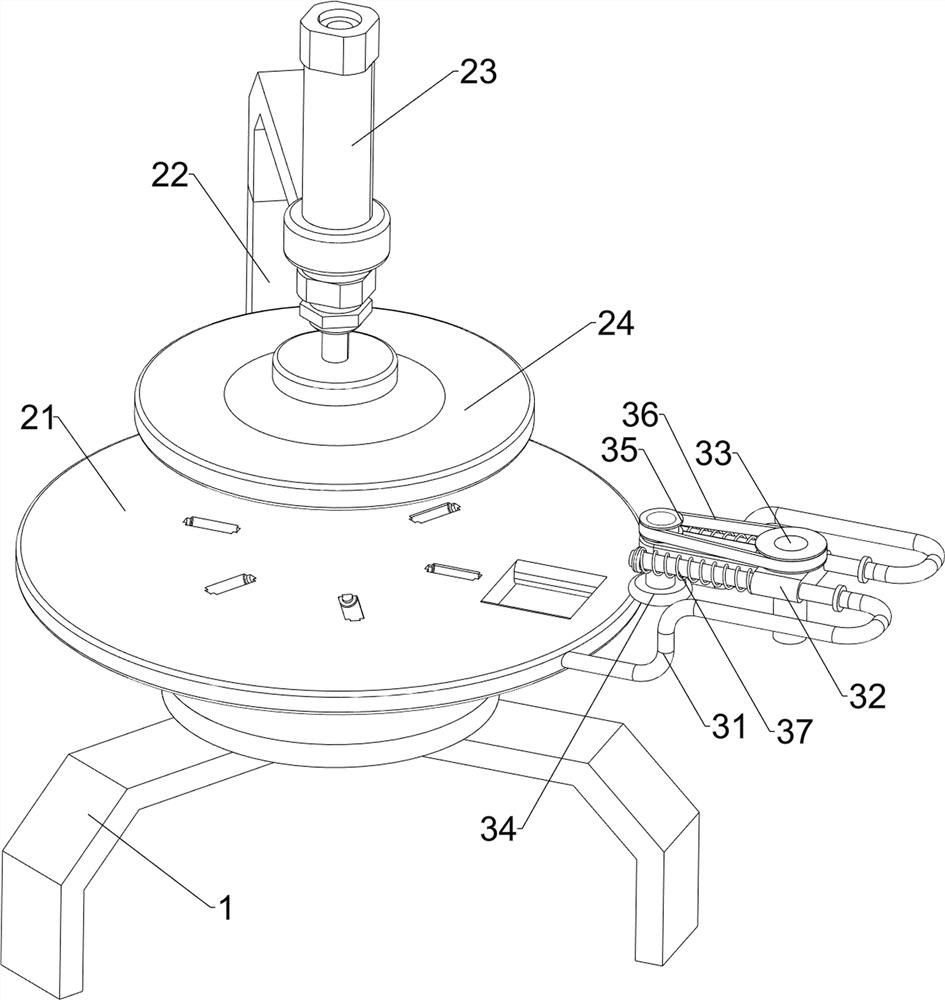

[0025] A device for cutting and reinforcing the outer side of a solid wood chopping board, such as figure 1 , figure 2 with image 3 As shown, it includes a base 1, a placing mechanism 2, a cutting mechanism 3, a rotating mechanism 4 and a driving mechanism 5. The upper middle part of the base 1 is provided with a placing mechanism 2, the right side of the placing mechanism 2 is provided with a cutting mechanism 3, and the upper right side of the base 1 A rotating mechanism 4 is provided, and a driving mechanism 5 is arranged on the rotating mechanism 4 .

[0026] The placement mechanism 2 includes a placement tray 21, a first mounting frame 22, a cylinder 23 and a pressure plate 24. The upper middle part of the base 1 is slidingly provided with the placement tray 21, and an elastic member is arranged between the middle side of the bottom of the placement tray 21 and the base 1. The base 1. The upper rear side is provided with a first mounting frame 22, and the first mounti...

Embodiment 2

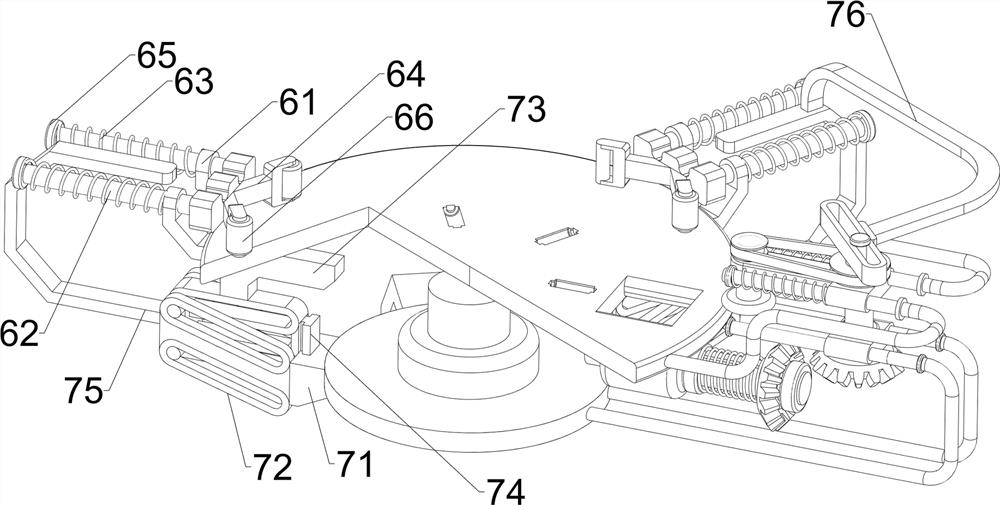

[0032] On the basis of Example 1, such as Figure 4 As shown, a centering mechanism 6 is also included, and the centering mechanism 6 includes a fourth mounting bracket 61, a sliding rod 62, a third spring 63, a connecting frame 64, a limit ring 65 and a third roller 66, placed on the outside of the disk 21 Three pairs of fourth mounting brackets 61 are evenly spaced, and sliding rods 62 are provided on the fourth mounting brackets 61. Limiting rings 65 are provided on the outside of the sliding rods 62. The third springs 63 are connected between each other, and the third springs 63 are respectively sleeved on the sliding rods 62. A connecting frame 64 is arranged between the inner sides of the sliding rods 62 on the same side, and a third roller 66 is arranged on the inner side of the connecting frame 64 in a symmetrically rotating manner.

[0033] People move the slide bar 62 inwardly through the tool, and the slide bar 62 will drive the connecting frame 64 to move inwardly,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap