Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Solid wood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid wood is a term most commonly used to distinguish between ordinary lumber and engineered wood, but it also refers to structures that do not have hollow spaces. Engineered wood products are manufactured by binding together wood strands, fibers, or veneers with adhesives to form a composite material. Engineered wood includes plywood, oriented strand board (OSB) and fiberboard. The fact that a product is made from solid wood is often touted in advertisements. However, using solid wood has advantages and disadvantages.

Biological comprehensive treatment method of indoor decoration pollution

InactiveCN104707472ANo secondary pollutionPracticalLiquid surface applicatorsDispersed particle separationSolid woodEnzyme

Owner:于清奎

Solid wood bending processing method with directional bending function

ActiveCN109352767AReduce absorptionSolving Regulatory IssuesWood treatment detailsThermal wood treatmentSolid woodPulp and paper industry

Owner:GUANGDONG YIHUA TIMBER IND

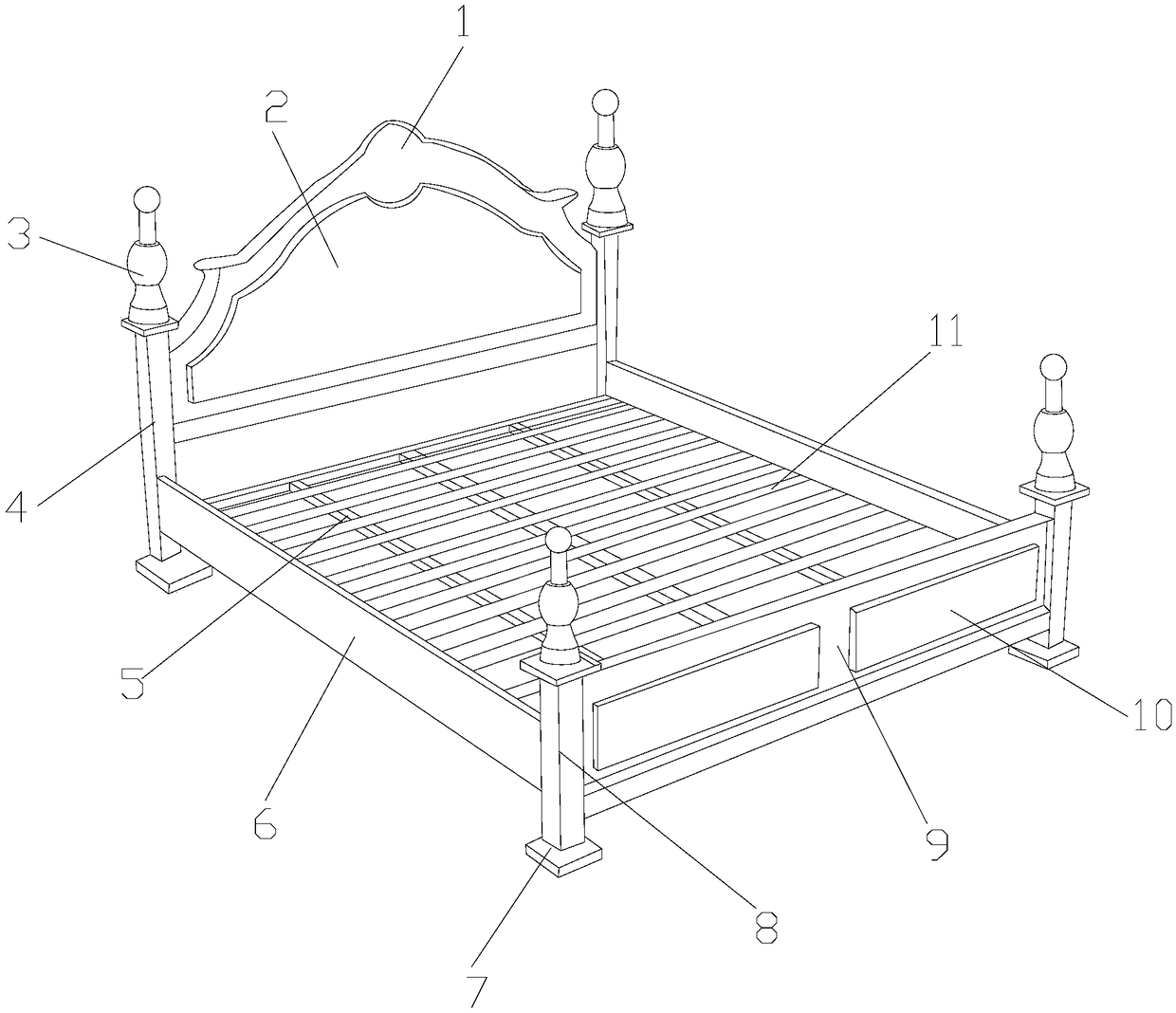

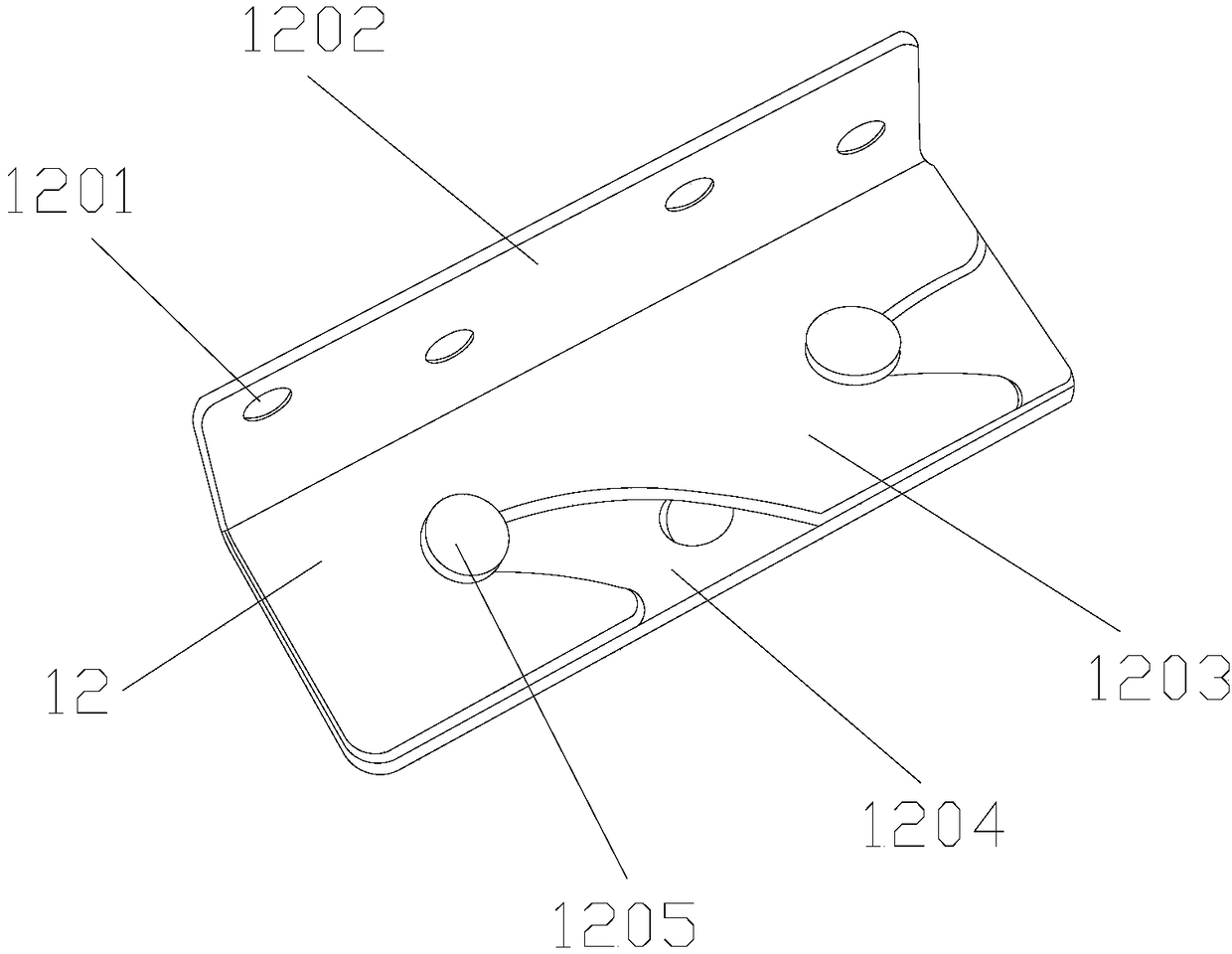

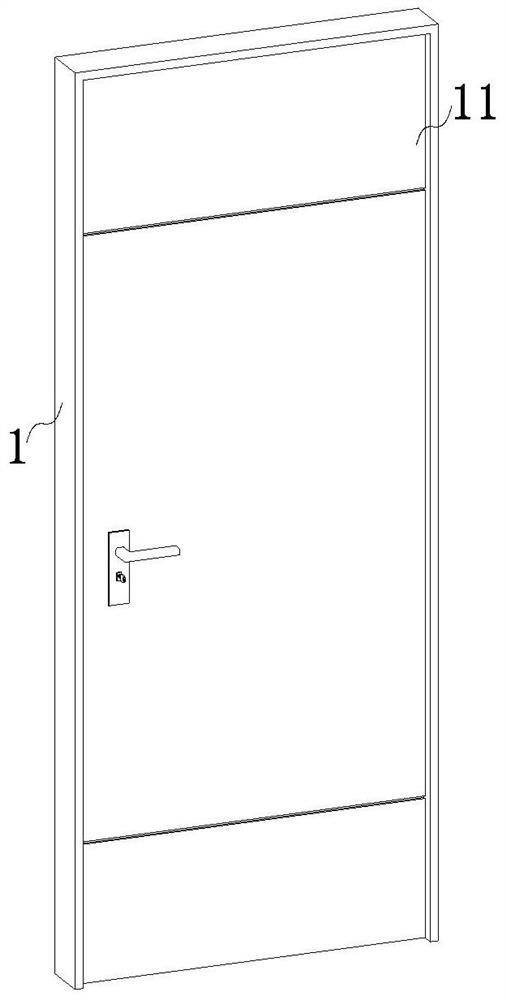

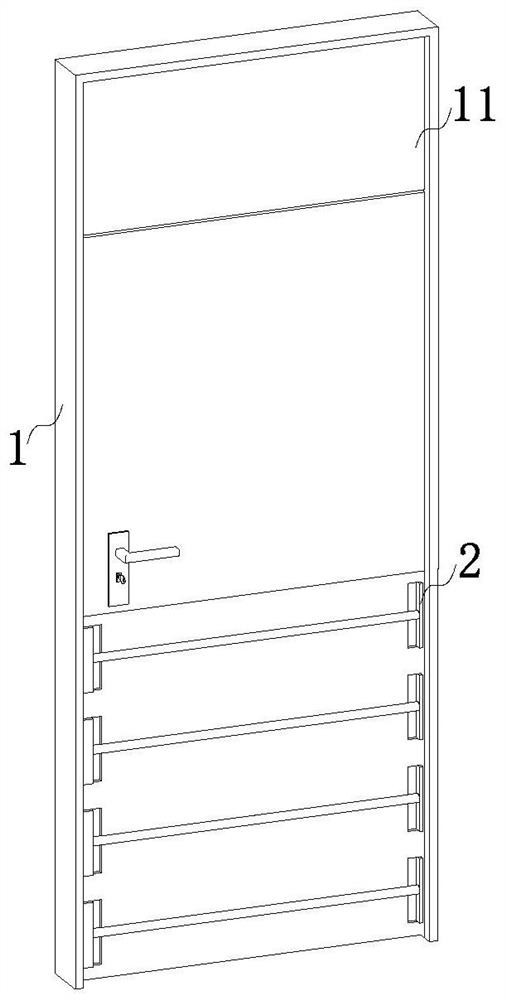

Integrated solid wood door plate and wood door thereof

The invention relates to the technical field of doors and windows, in particular to an integrated solid wood door sheet and a wooden door thereof.The integrated solid wood door sheet comprises a door frame, the right side, close to the corner, of the inner surface of the door frame is rotationally connected with a door sheet through hinges, and the lower ends of the outer surfaces of the left and right sides of the door sheet are movably connected with anti-pinch mechanisms; the anti-pinch mechanism comprises a plurality of first movable grooves, first sliding grooves and first springs, the first movable grooves are symmetrically formed in the lower ends of the outer surfaces of the left side and the right side of the door plate, and anti-pinch plates are slidably connected into the first movable grooves. By arranging the anti-pinch mechanism, the situation that a child is pinched due to the fact that the anti-pinch plate and the door frame are combined to generate large extrusion force is prevented, the safety of home life is improved, in addition, by arranging the fixing mechanism, the anti-pinch plate is fixed through mutual clamping of a clamping rod and a first clamping groove, and the safety of home life is improved. The situation that a gap is generated between the anti-clamping plate and the door frame due to the fact that the anti-clamping plate is moved is prevented, and the anti-theft performance and privacy of the device are improved.

Owner:朱小帅

Decorative wall panel

InactiveCN109386100ASoundproof and confidentialFireproof and beautifulCovering/liningsFlooringSolid woodCement board

Owner:JIANGSU KANGMEI NEW MATERIAL TECH

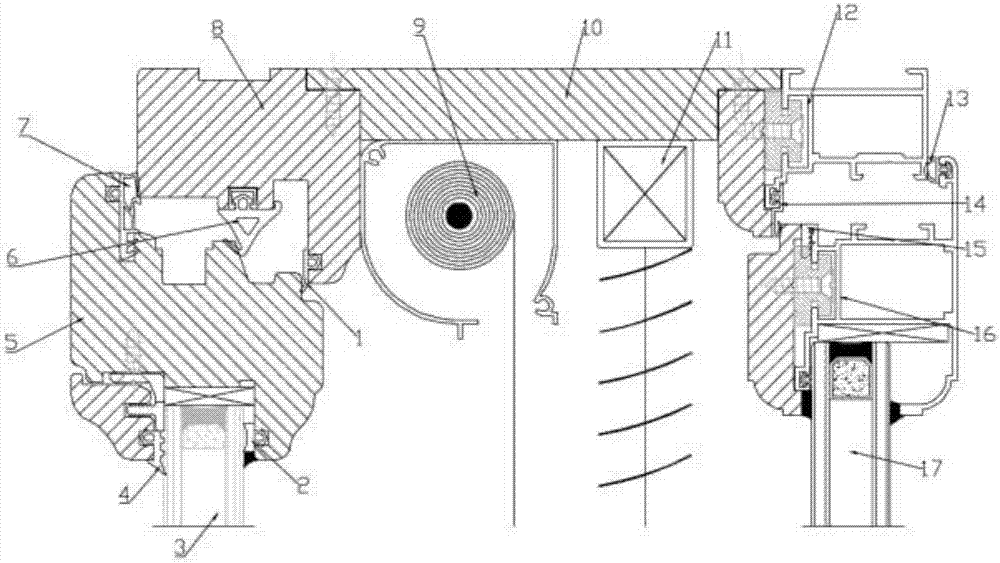

Multi-functional wood-aluminum composite window

InactiveCN106948714APromote regenerationSustainableBurglary protectionInsect protectionFinger jointEngineering

Owner:浙江研和新材料股份有限公司

Chopping board production device and using method thereof

Owner:南宁市金春商贸有限责任公司

Curved surface veneering process of solid wood furniture

Owner:美克国际家私(天津)制造有限公司

Recycled solid wood finger-jointed multilayer composite plate

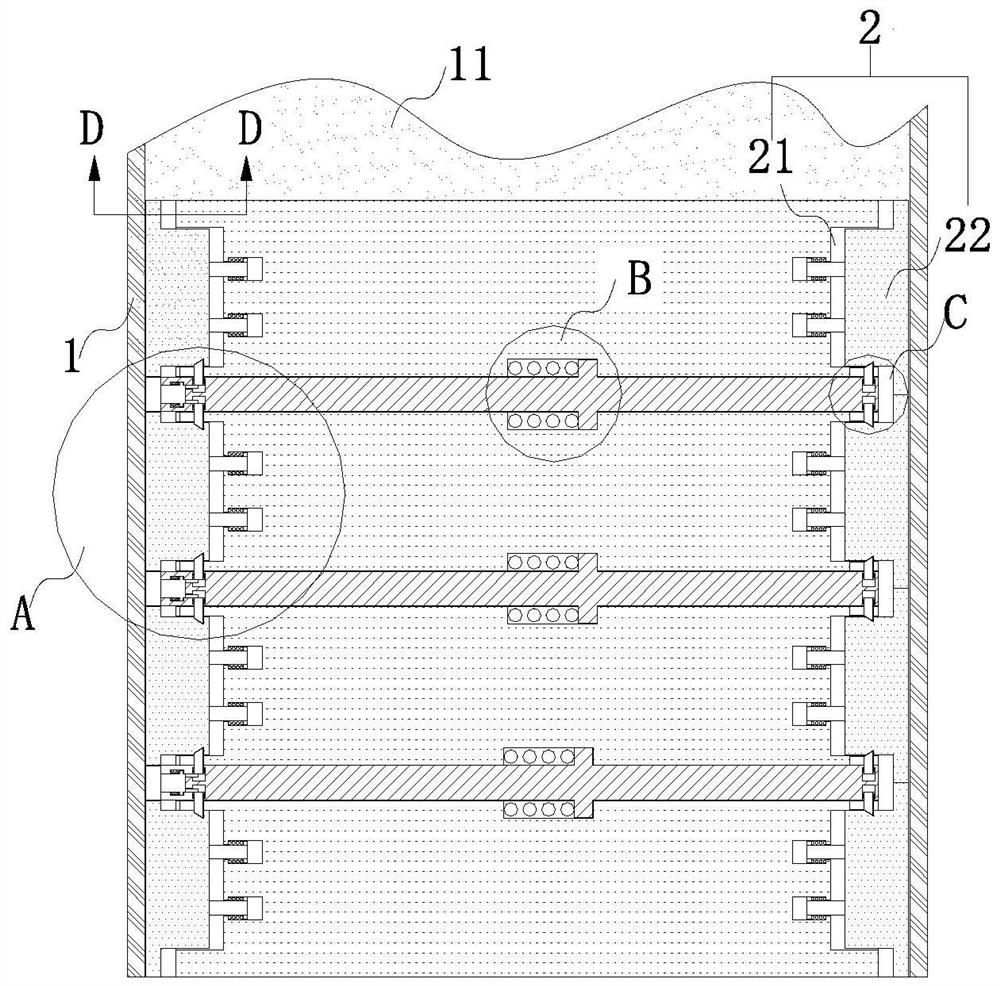

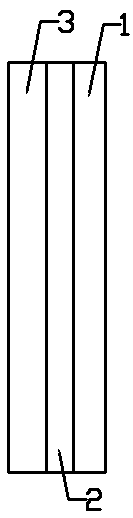

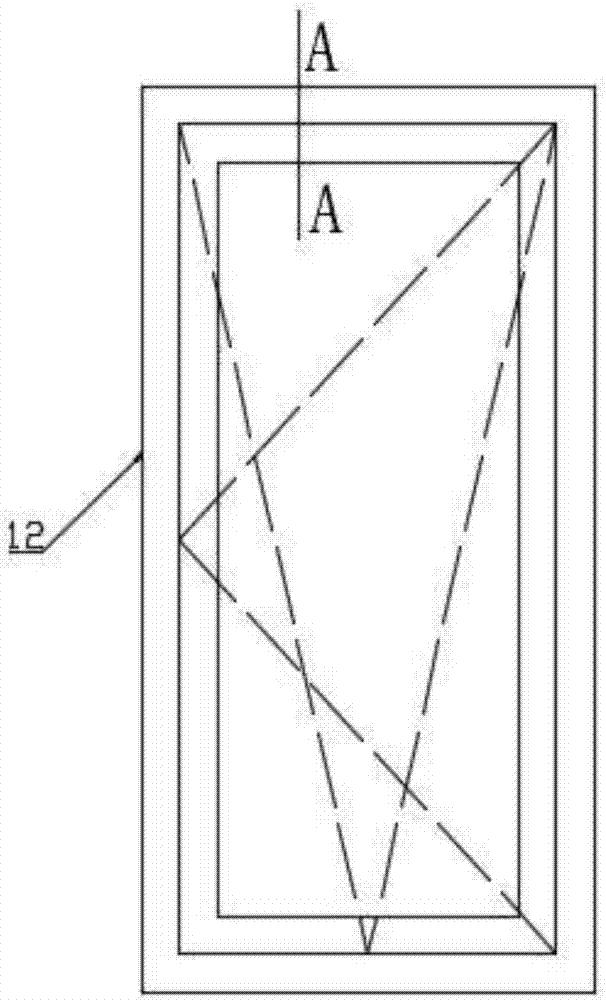

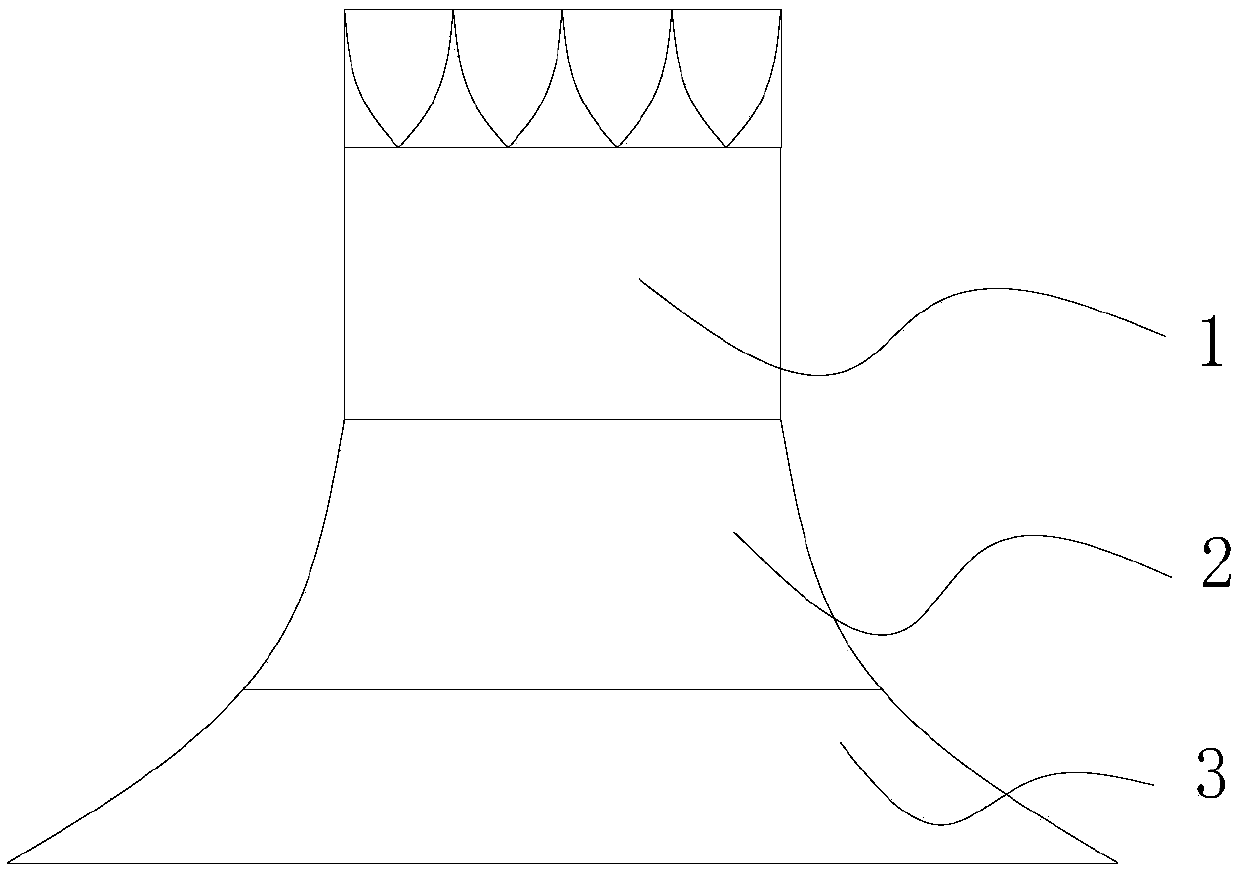

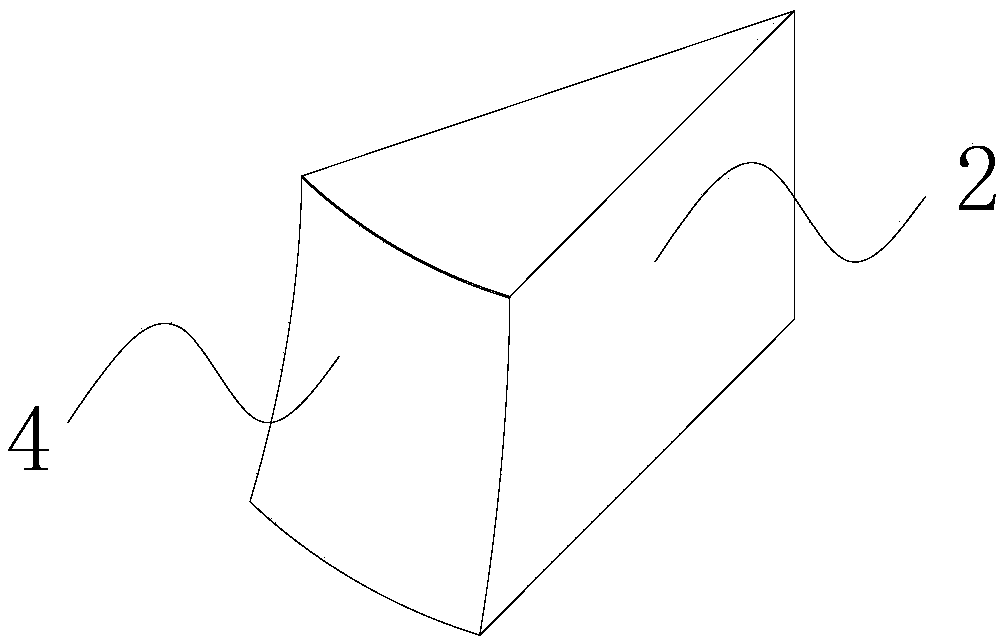

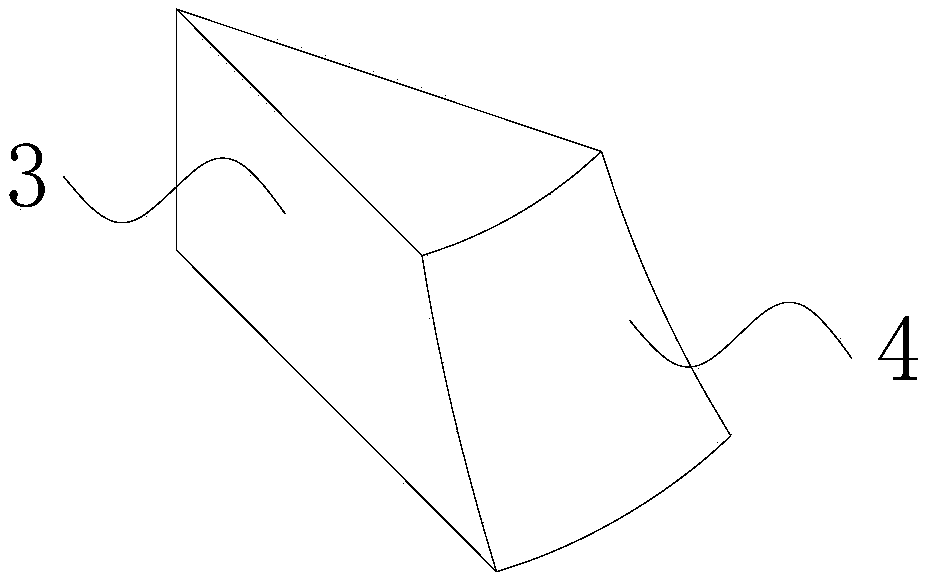

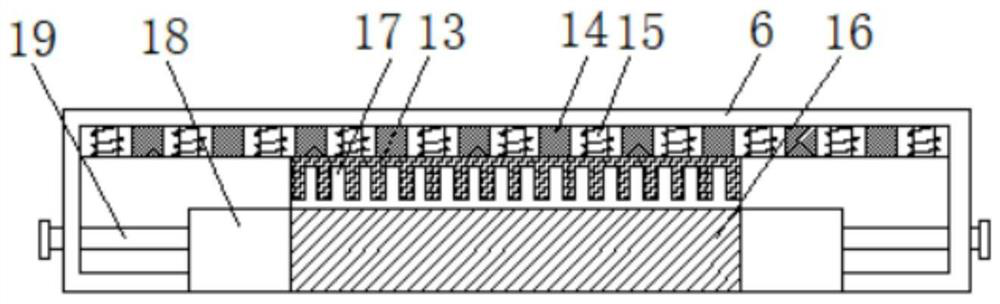

The invention discloses a recycled solid wood finger-jointed multilayer composite plate. The recycled solid wood finger-jointed multilayer composite plate comprises a solid wood layer (1) and a plurality of composite plate layers. The recycled solid wood finger-jointed multilayer composite plate is characterized in that a mucilage glue layer (6) is arranged between the solid wood layer and the first composite plate layer (2),a mucilage glue layer (7) is arranged between the first composite plate layer and a second composite plate layer (3), and a mucilage glue layer (8) is arranged between the second composite plate layer and a third composite plate layer (4). The solid wood layer is formed by the steps that a plurality of solid wood strips with tooth grooves (13) are mutually embedded and bonded to form a long strip through a mucilage glue layer (10), and a plurality of the long strips are bonded to form a solid wood plate through a mucilage glue layer (5). The recycled solid wood finger-jointed multilayer composite plate is formed by the steps that a plurality of composite plates with tooth grooves (11) are mutually embedded and boned to form a long strip through a mucilage glue layer, a plurality of the long strips are mutually embedded, and then the recycled solid wood finger-jointed multilayer composite plate is formed through the bonding of a mucilage glue layer (12).

Owner:NANCHONG LONGHUANG BUILDING MATERIALS

Clamping groove equipment for cutting and reinforcing outer side of solid wood cutting board

PendingCN113119247AImprove work efficiencyEasy to operateWood mortising machinesWood slotting machinesSolid woodStructural engineering

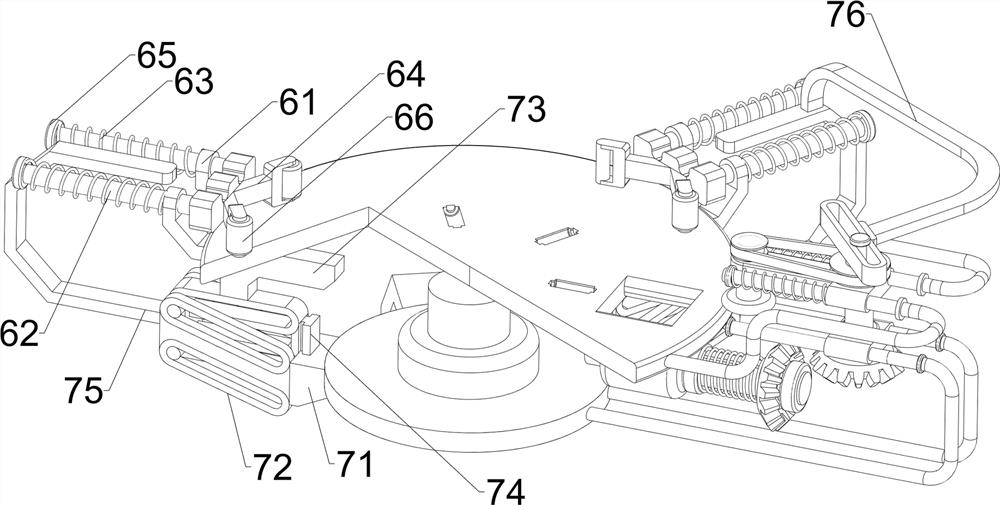

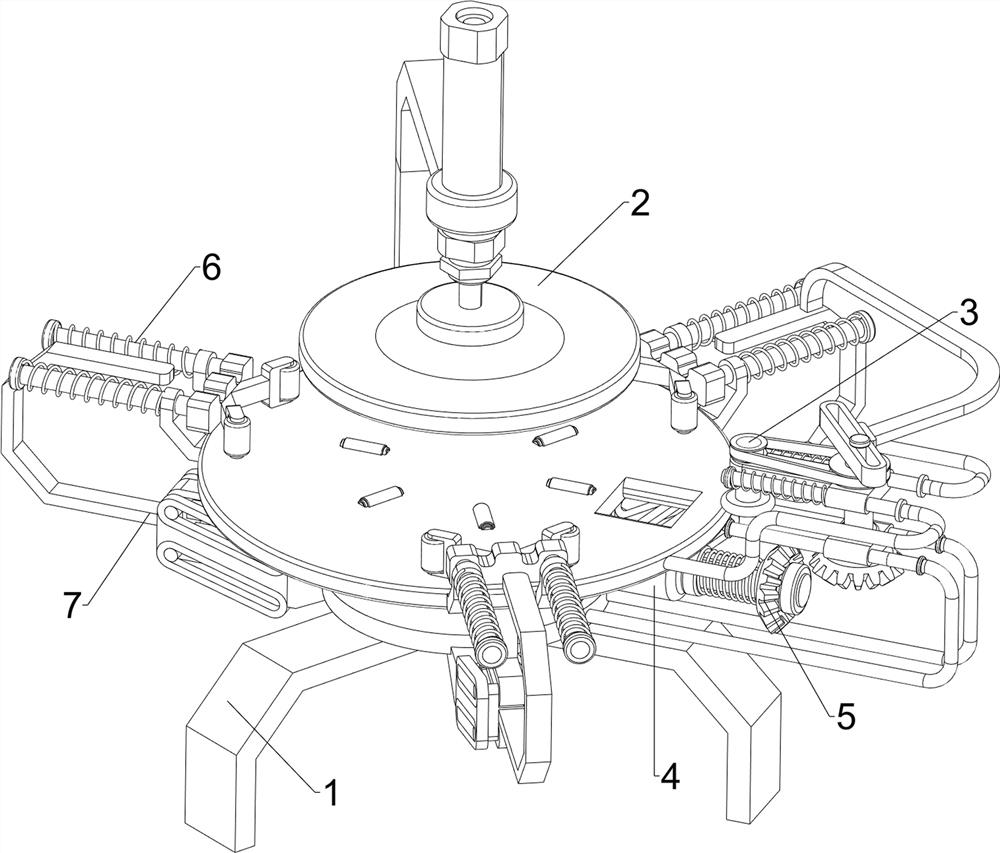

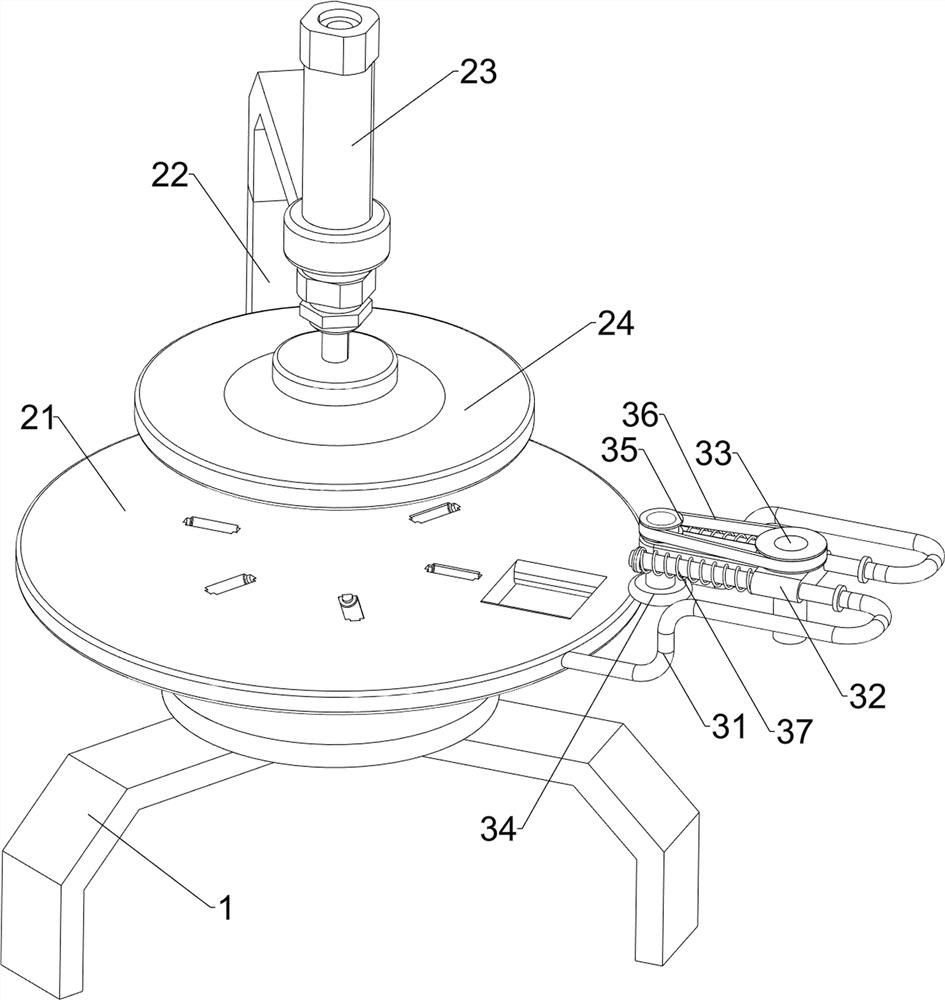

The invention relates to clamping groove equipment, in particular to clamping groove equipment for cutting and reinforcing the outer side of a solid wood cutting board. The clamping groove equipment for cutting and reinforcing the outer side of the solid wood cutting board is automatic in grooving, accurate in grooving position and convenient to use. According to the technical scheme, the clamping groove equipment for cutting and reinforcing the outer side of the solid wood cutting board comprises a base, a placing mechanism, a cutting mechanism, a rotating mechanism and a driving mechanism; the placing mechanism is arranged at the upper middle part of the base; the cutting mechanism is arranged on one side of the placing mechanism; the rotating mechanism is arranged on one side of the base; and the driving mechanism is arranged on the rotating mechanism. The clamping groove equipment has the beneficial effects that under the action of the cutting mechanism, a second rotating shaft can drive a first rolling wheel and a first bevel gear to rotate, the first bevel gear can drive a cutting wheel to rotate, meanwhile, the first rolling wheel can drive a wood cutting board to rotate, and therefore the cutting wheel conducts outer side grooving work on the wood cutting board.

Owner:廖玉玲

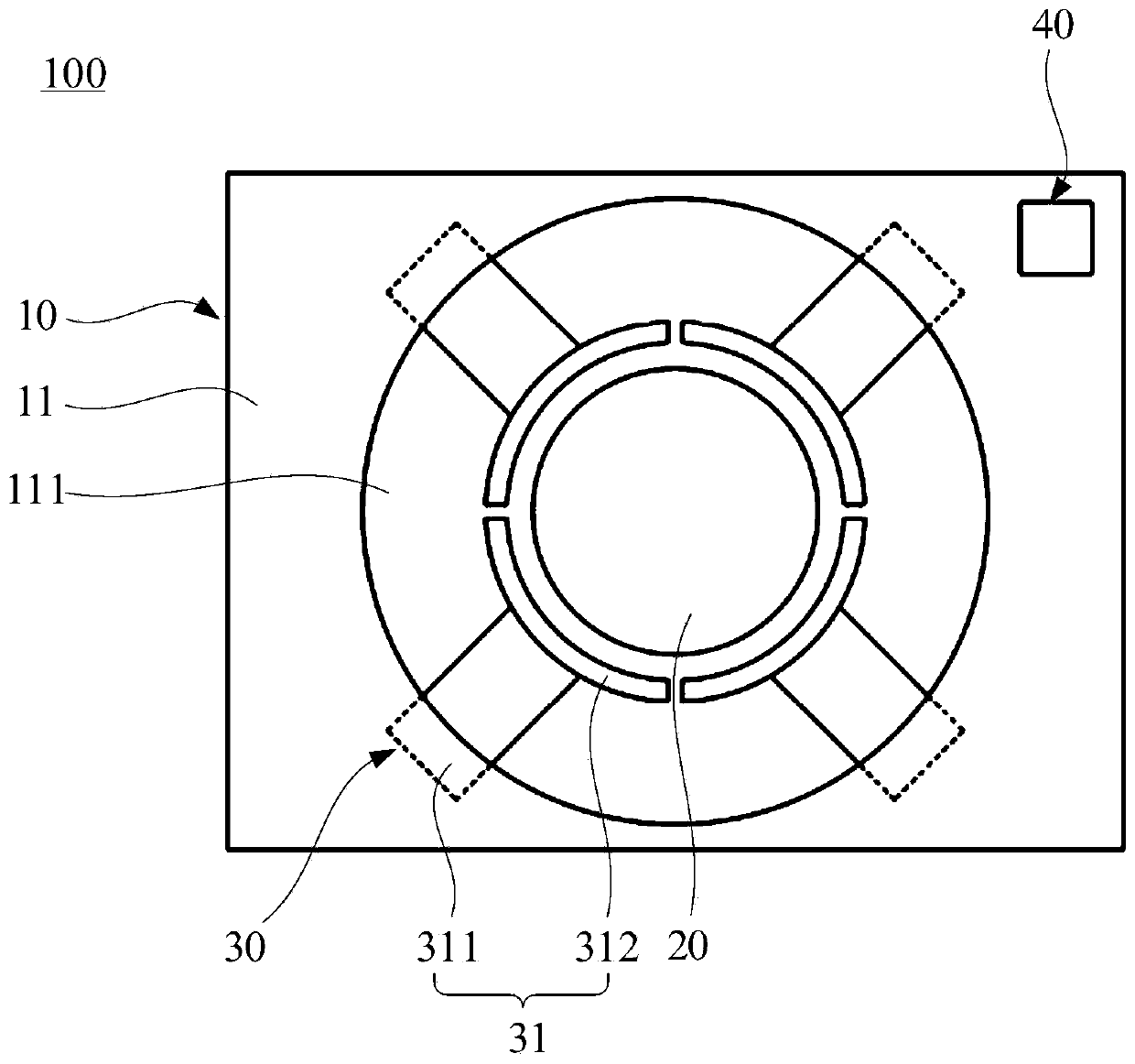

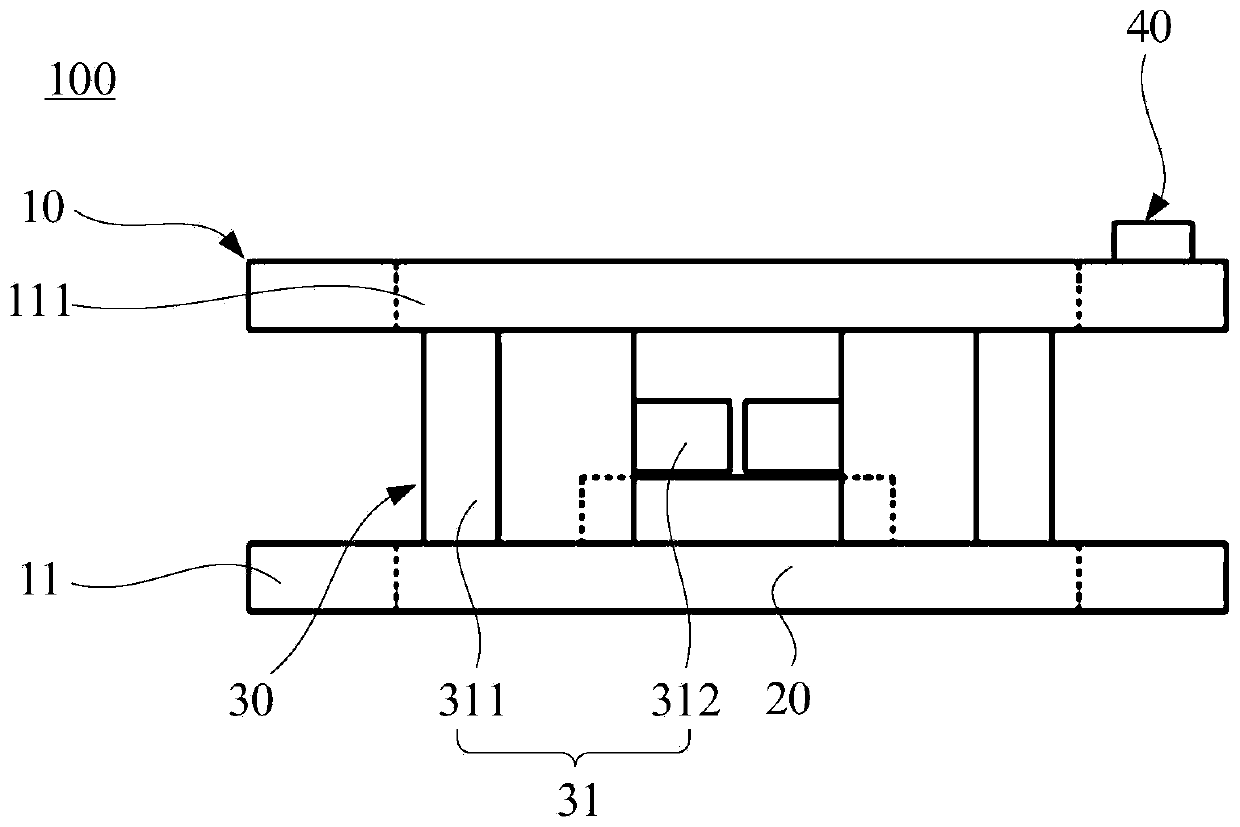

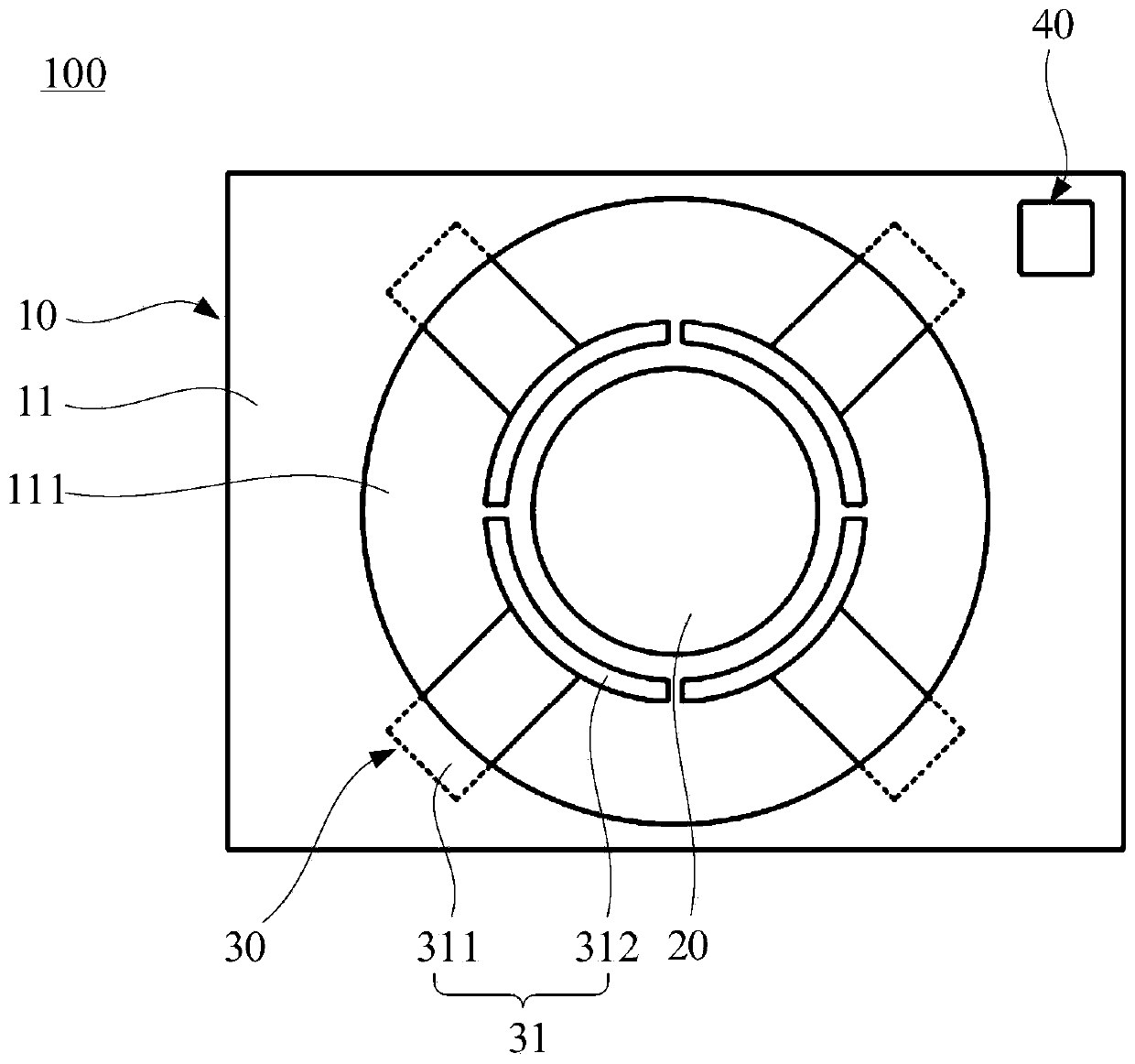

Pressure measuring machine for formaldehyde-free solid wood composite floor

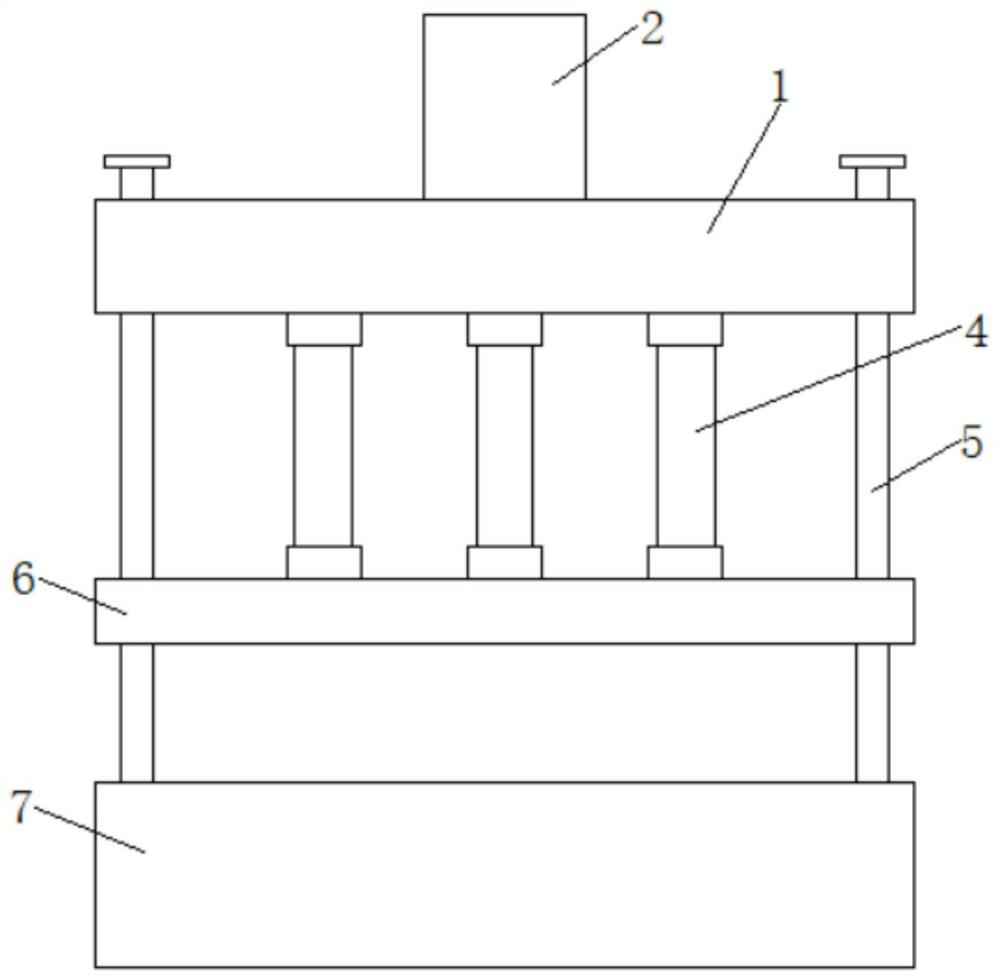

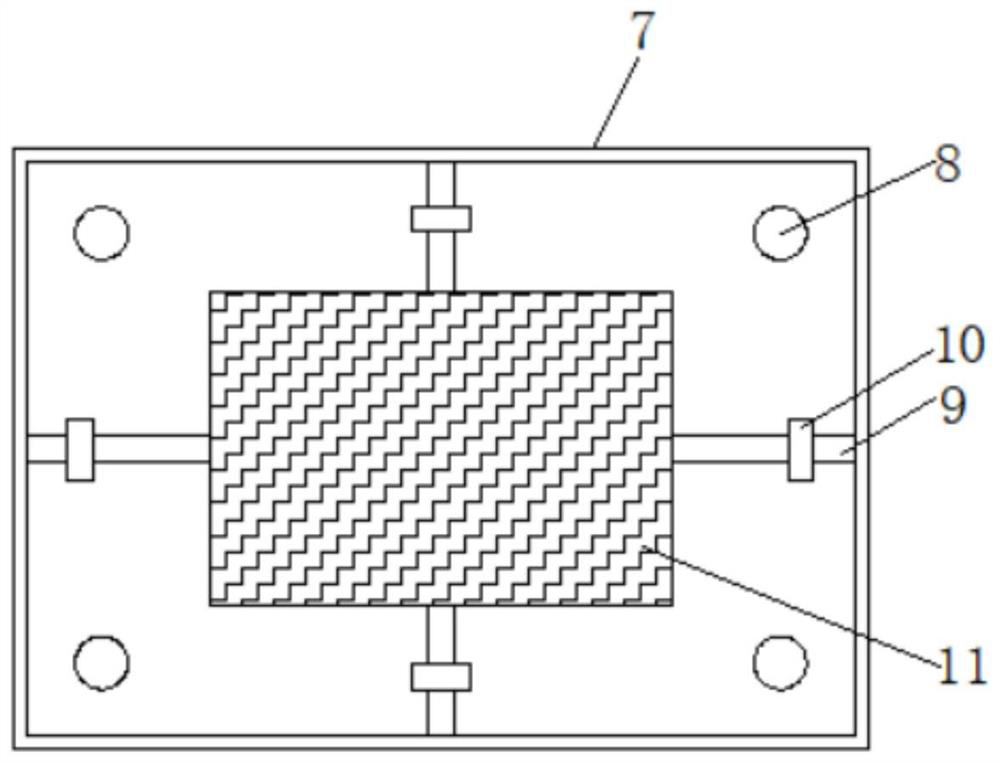

PendingCN112268801AAccurate dataMaintain stabilityMaterial strength using tensile/compressive forcesPneumatic cylinderSolid wood

The invention discloses a pressure measuring machine for a formaldehyde-free solid wood composite floor, and belongs to the technical field of formaldehyde-free solid wood composite floors, the pressure measuring machine comprises a pressing machine, a pneumatic cylinder is installed at the top of the pressing machine, a sliding rod is connected to one side of the interior of the pressing machine,a fixing column is connected to the bottom of the pressing machine, and a pressing head is installed at the bottom of the fixing column; a pressure detection plate is installed in the pressure head,a fixing plate is installed on one side of the pressure detection plate, a threaded rod is connected to one side of the fixing plate, a clamping block is arranged at the top of the pressure detectionplate, a clamping groove is connected to one side of the clamping block in a clamped mode, and a pressure-resistant block is connected to the upper portion of the interior of the pressure head. According to the invention, a plate is placed on a non-slip mat, and then baffle blocks slide on the slide rails, so that the surrounding baffle blocks fix the plate, and the plate is located below the pressure detection plate, so that the plate does not slip in the detection process under the action of the non-slip mat and the baffle blocks, and the detected data is more accurate.

Owner:JIANGSU C&P WOOD TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap