Ejection cooling type thermoelectric power generation device

A temperature difference power generation and cooling technology, which is applied in the direction of ocean energy power generation, generator/motor, electrical components, etc., can solve the problems of power generation efficiency reduction, reliability reduction, power consumption, etc., and achieve long-term stable operation and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

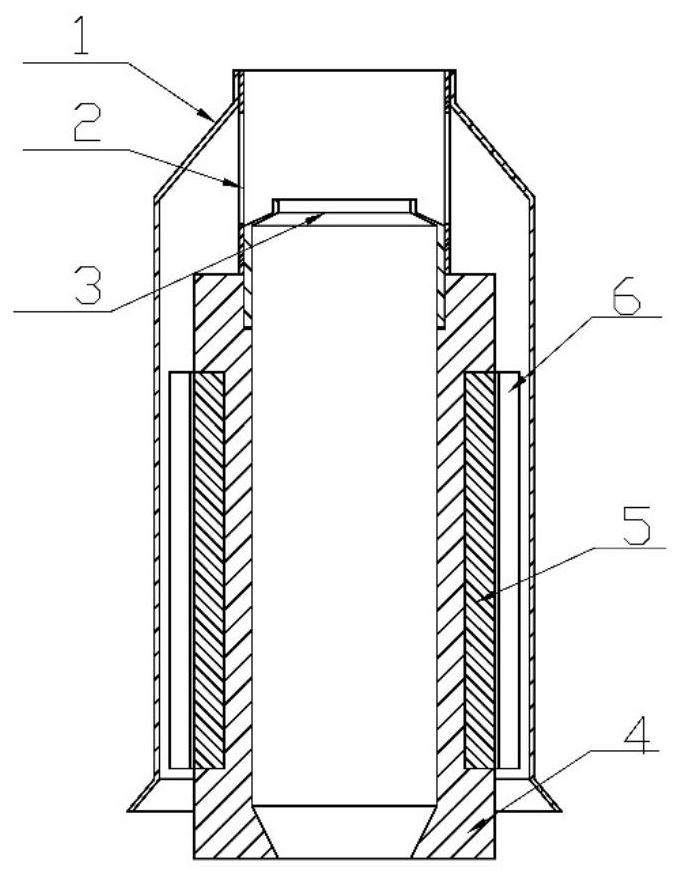

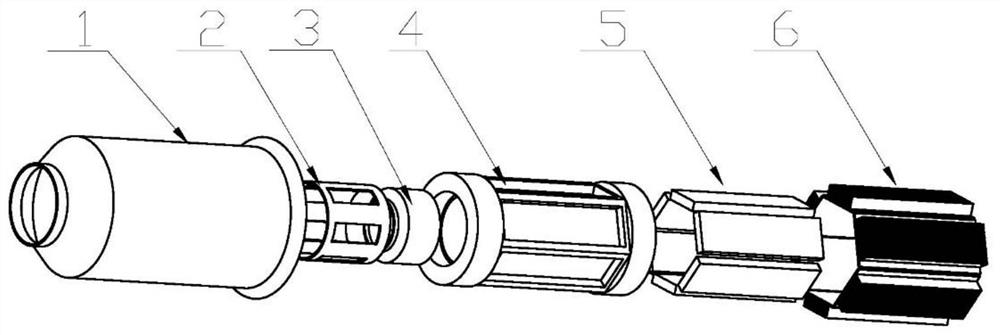

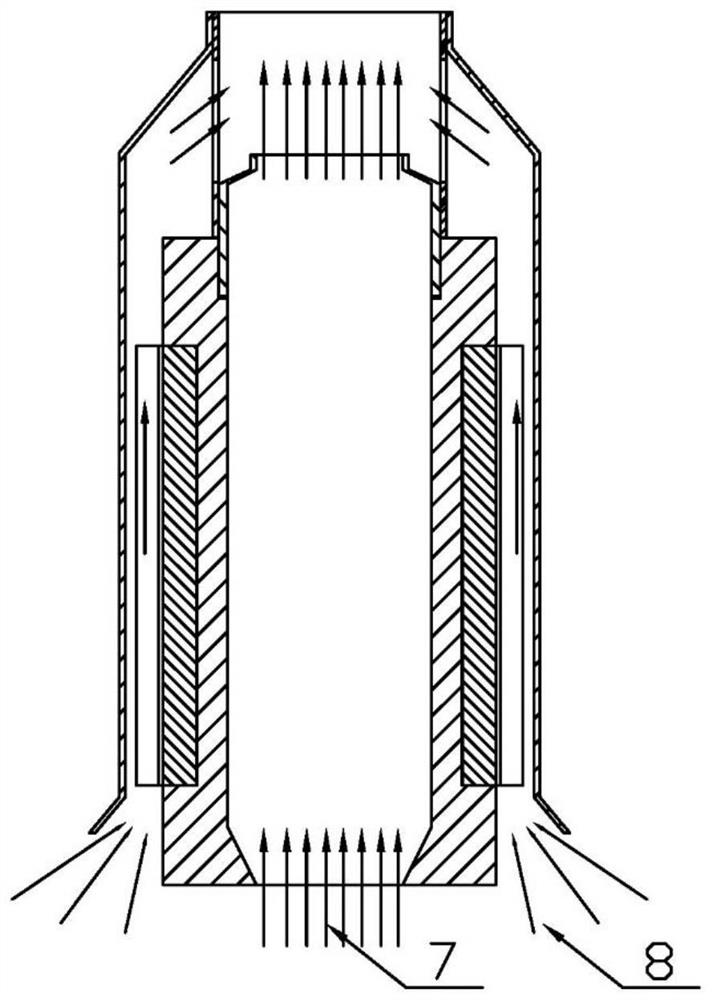

[0028] see figure 1 and figure 2 , The injection-cooled thermoelectric device of this embodiment includes a draft cover 1 , a connector 2 , a shrink tube 3 , a thermoelectric generator cavity 4 , a thermoelectric sheet 5 , and a cooling fin 6 . The shrink tube 3 is installed at the outlet of the thermoelectric generator cavity 4 through threaded connection, and the inner cavity of the shrink tube 3 is concentric with the inner cavity of the thermoelectric generator cavity 4 . One end of the connector 2 is connected to the outlet of the drainage cover 1 to ensure concentricity, and the other end is connected to the shrink tube 3 . The connecting piece 2 is a hollow cylinder supported between the thermoelectric generator cavity 4 and the diversion cover 1 , which supports and ensures that the diversion cover 1 and the thermoelectric generator cavity 4 are concentric. A liquid passage gap is formed between the drainage cover 1 and the outer wall of the thermoelectric generator ca

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap