Nozzle flange capable of preventing foreign matters and combustion chamber

A nozzle flange, foreign matter prevention technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of uneven outlet equivalence ratio of nozzle premixing channel, uneven fuel jet, difficult cleaning process, etc., to prevent The effect of blocking, reducing variance, ensuring fuel supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

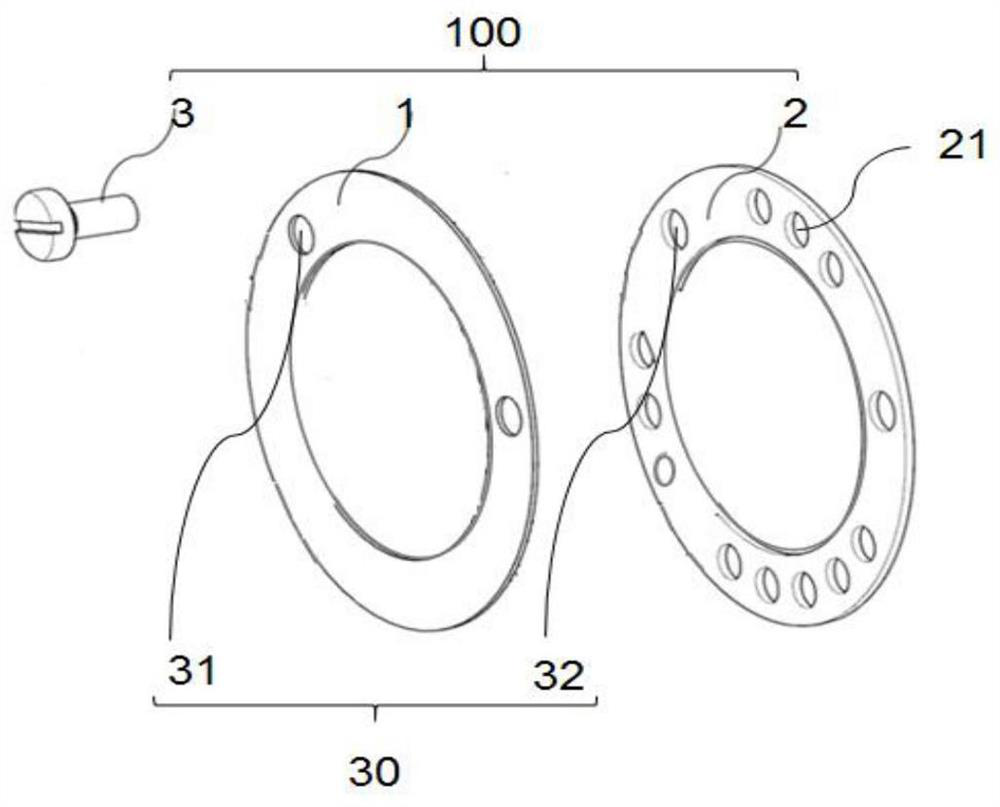

[0036] Such as figure 1 As shown, the nozzle flange for preventing foreign matter includes a filter screen 1 , a throttling orifice plate 2 and a fixing part 3 arranged inside the nozzle flange.

[0037] Specifically, the filter screen 1 is used to filter foreign matter entering the nozzle flange. The filter screen 1 has a ring structure, and the nozzle flange is provided with at least one layer of filter screen 1. The mesh number and wire diameter of the filter screen are not limited. Choose the hole diameter. In one embodiment of this application, the nozzle flange is provided with a layer of filter screen 1 .

[0038] Throttle orifice 2 is arranged on the downstream of filter screen 1, and is coaxial with filter screen 1, and throttle orifice 2 is annular structure, and throttle orifice 2 is provided with a plurality of hole structures 21, and hole structure 21 The positions correspond to the nozzle flange fuel inlet holes one by one. In addition, the hole diameter of the ho

Embodiment 2

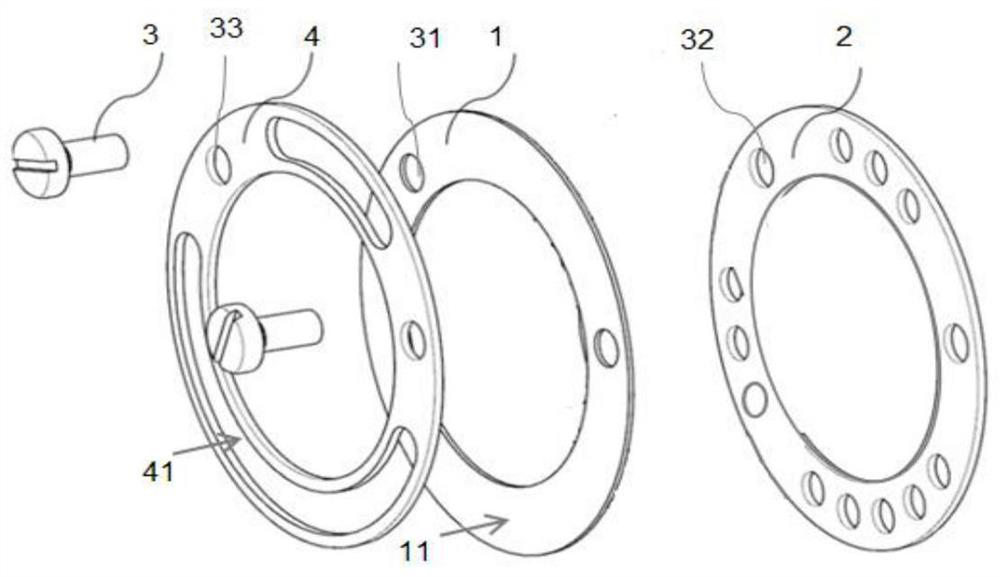

[0042] Such as figure 2 As shown, the nozzle flange for preventing foreign matter includes a first clamping plate 4 , a filter screen 1 , a throttling orifice plate 2 and a fixing part 3 arranged inside the nozzle flange. In an embodiment of this application, the first splint 4, the filter screen 1, and the orifice plate 2 are arranged coaxially in sequence.

[0043] Wherein, the first splint 4 is arranged upstream of the filter screen 1 , the first splint 4 is in an annular structure, and the first splint is provided with a hollow structure 41 corresponding to the filter portion 11 of the filter screen 1 . By arranging the first splint on the nozzle flange, the filter screen is positioned, and the operation convenience of disassembly and maintenance such as filter screen cleaning and replacement is improved.

[0044] The filter screen 1 is used to filter the foreign matter entering the nozzle flange. The filter screen 1 has a ring structure, and the nozzle flange is equipped w

Embodiment 3

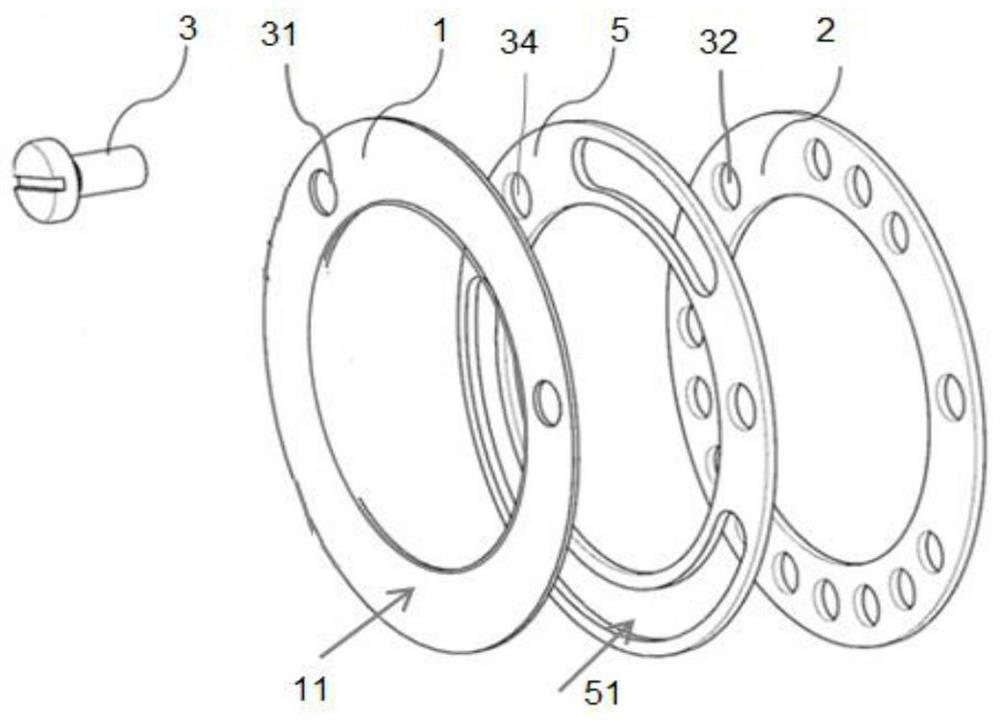

[0049] Such as image 3 As shown, the nozzle flange for preventing foreign matter includes a filter screen 1 , a throttle orifice plate 2 , a second clamping plate 5 and a fixing part 3 arranged inside the nozzle flange. In one embodiment of this application, the filter screen 1 , the second clamping plate 5 and the throttle orifice plate 2 are arranged coaxially in sequence.

[0050] Wherein, the second splint 5 is arranged downstream of the filter screen 1 , the second splint 5 is in an annular structure, and the second splint 5 is provided with a hollow structure 51 corresponding to the filter portion 11 of the filter screen 1 . By arranging the second splint on the nozzle flange, the filter screen is positioned, and the operation convenience of the filter screen cleaning, replacement and other disassembly and maintenance is improved.

[0051] The filter screen 1 is used to filter the foreign matter entering the nozzle flange. The filter screen 1 has a ring structure, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap