Refrigeration water dispenser

A water dispenser and casing technology, applied in the field of compression refrigeration water dispensers, can solve the problems of polluting drinking water and existing drinking water safety, and achieve the effects of high refrigeration efficiency and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

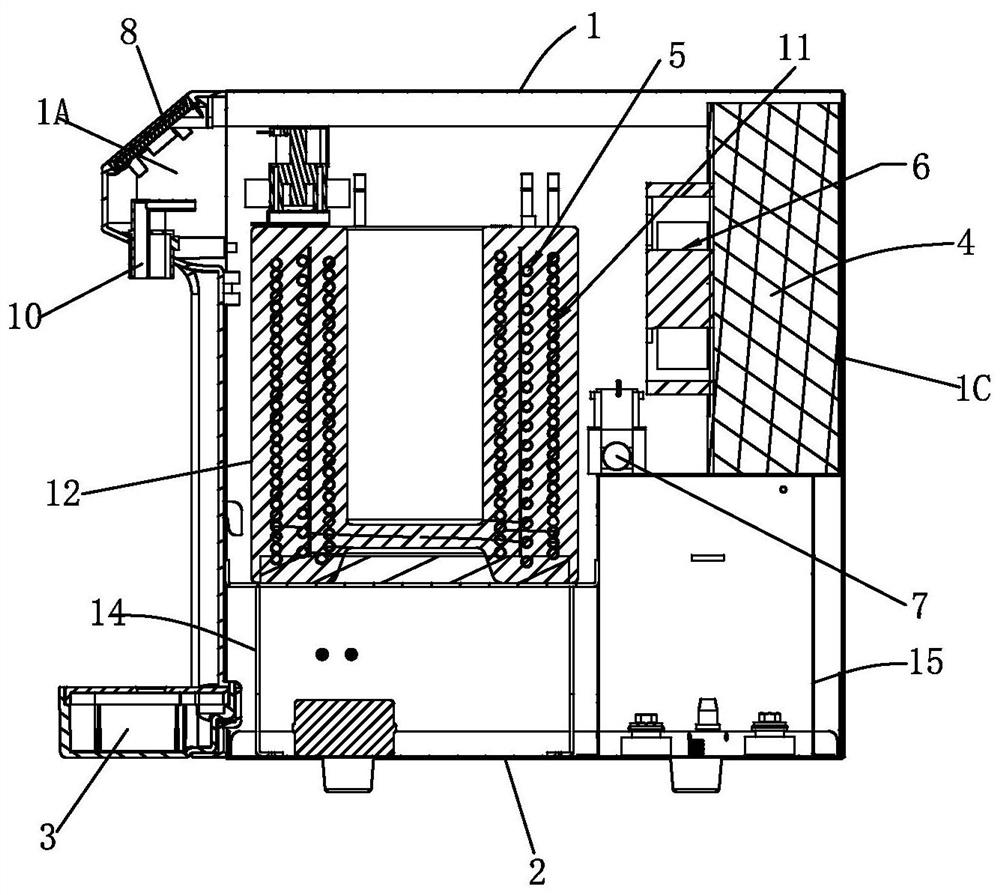

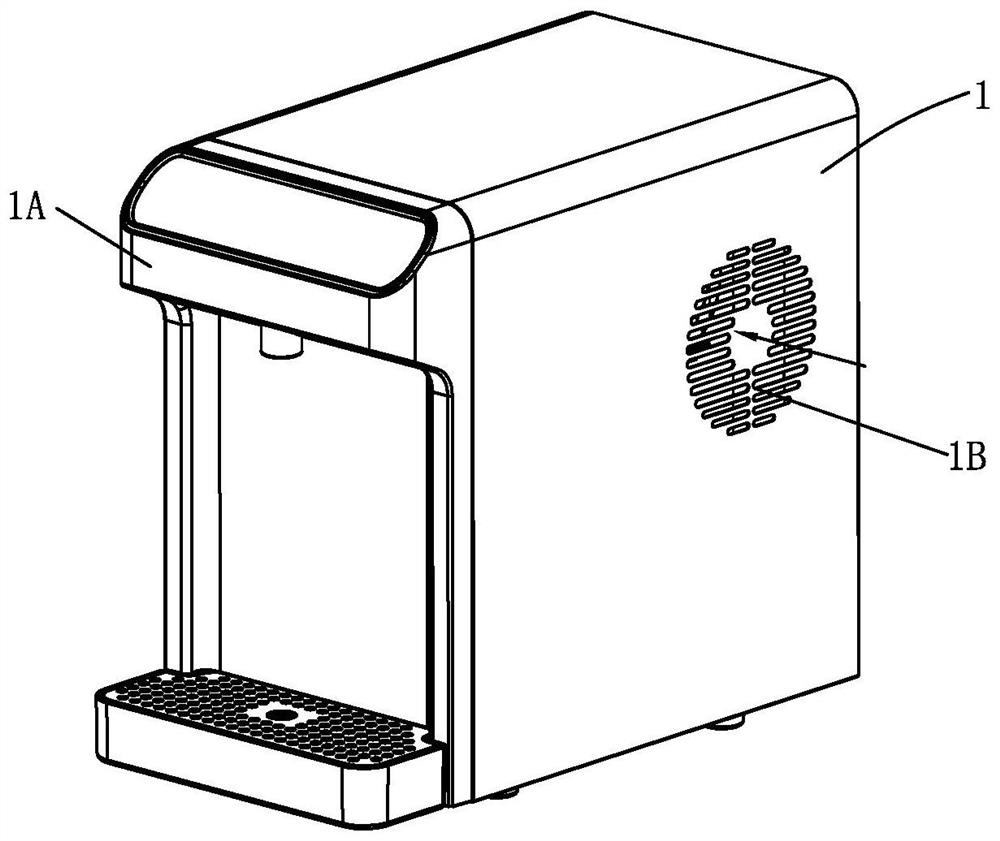

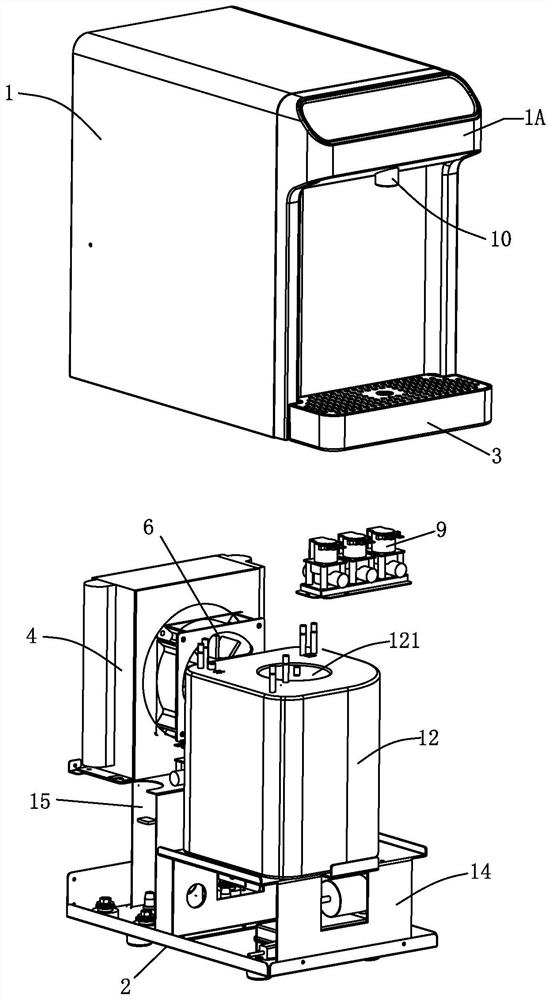

[0025] Such as figure 1 As shown, a cooling water dispenser includes a casing 1, a base 2, a water receiving tray 3 located at the front lower part of the casing, a compressor (not shown in the figure), a condenser 4, an evaporator 5, and a cooling fan 6 , the temperature controller 7 and the operating circuit board 8, the base 2 is embedded in the lower end of the casing 1, the casing 1 and the base 2 are fixedly connected; the cooling fan 6 is opposite to the condenser 4;

[0026] The front upper part of the casing 1 extends forward to form a control chamber 1A, the side wall of the casing 1 is provided with an air inlet hole 1B, and the rear wall is provided with an air outlet 1C;

[0027] Such as Figure 5 As shown, the evaporator 5 includes a cylinder part with upper and lower openings made of winding tubes, a refrigerant inlet pipe and a refrigerant outlet pipe,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap