Automatic multi-stage single-particle impact type sampler and sampling method

A multi-stage, single-particle technology, applied in the field of atmospheric science, can solve problems such as difficult to meet, cumbersome operation, inability to automatically replace the sample membrane, etc., and achieve the effect of flexible use and wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] The present invention will be further described below in connection with the accompanying drawings, but will not limit the scope of the invention in any way.

[0041] The automated multi-stage single-particle impact sample provided by the present invention can utilize a three-layer rotary sample stage, a custom rotating device, and an autonomous control system, can be automated and / or manualized sample, automatic or remote control replacement. Sample membrane, strong controllability, easy to operate, provide convenient and practical single-grain sampling equipment for fixed sources, mobile sources, etc.

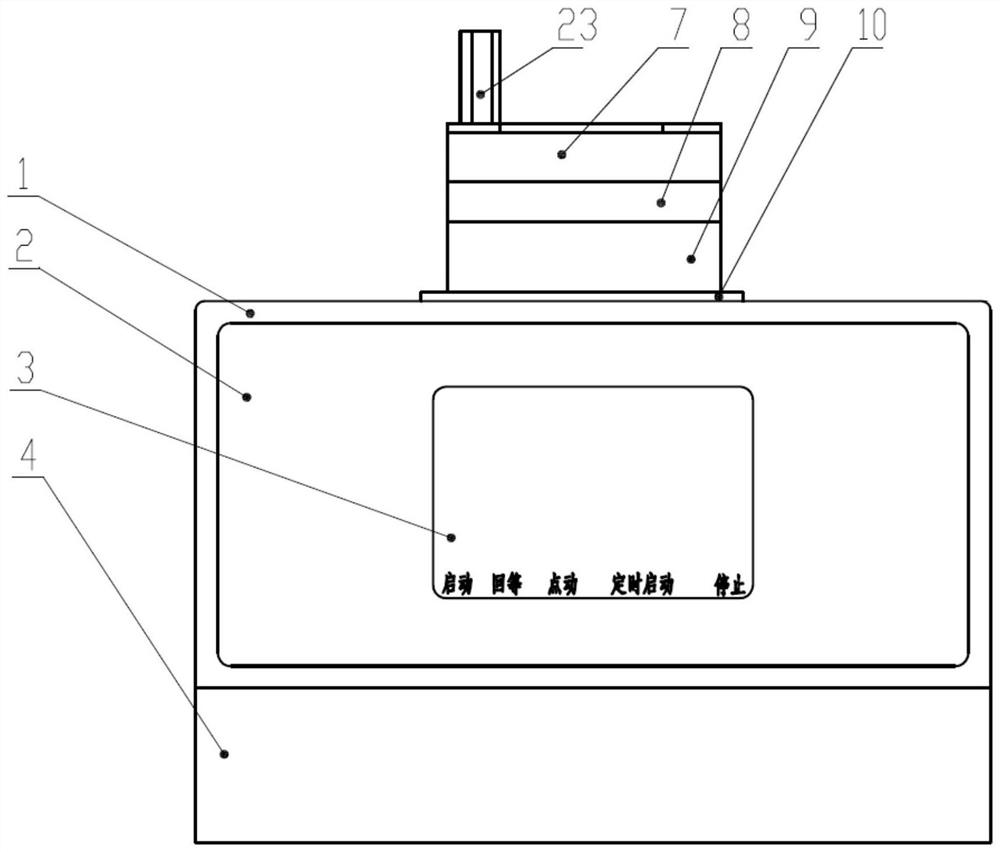

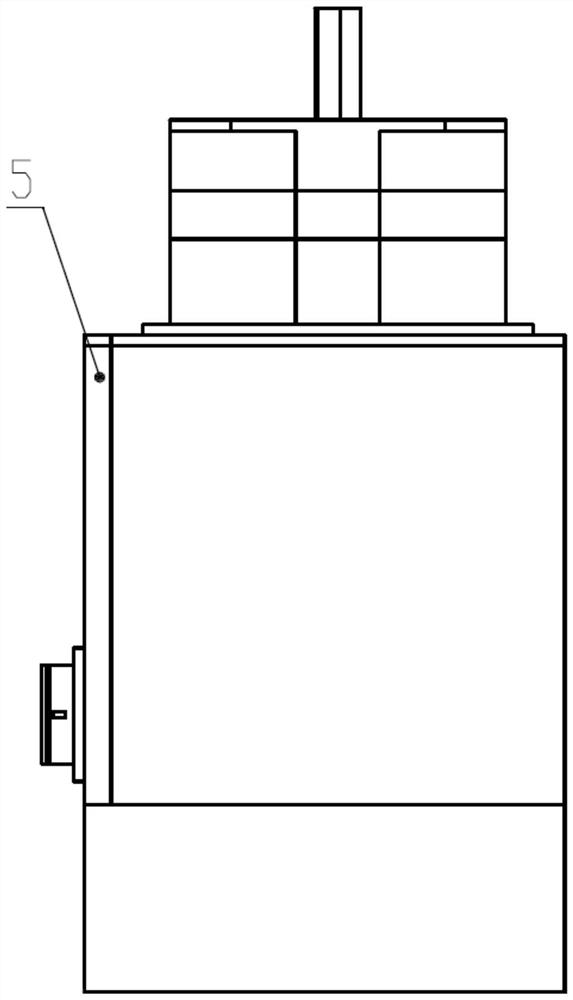

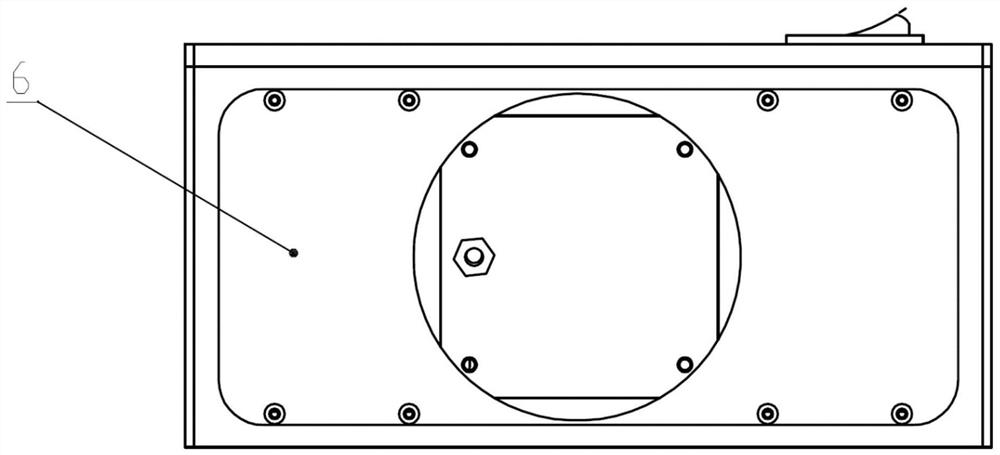

[0042] like Figure 1 ~ 4 As shown, the present invention is an automated multi-stage single-particle impact sampler, including: spin multi-stage sample head, power and rotation module, control and display module; the spin multi-stage sample head includes top Cover 7, upper rotary sample table 13, medium cover 8, medium-layer rotary sample table 12, lower cover 9, lower ro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap