Easily-welded low-yield-ratio quenched and tempered oil storage tank steel plate and manufacturing method thereof

A low yield ratio, oil storage tank technology, applied in the field of metallurgy, can solve the problems of high cost, low yield ratio, unfavorable welding, etc., and achieve the effect of uniform and stable performance, good welding toughness, and low yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

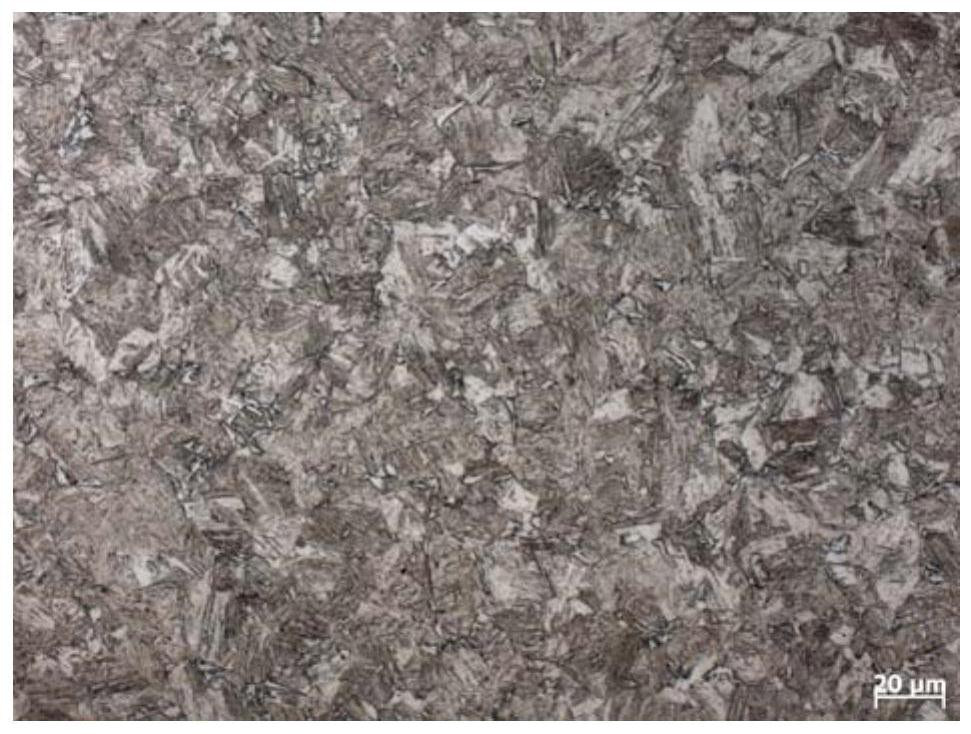

Image

Examples

Embodiment 1

[0038] The steel plate of this embodiment has a thickness of 12 mm and consists of the following components in weight percentage: C 0.09%, Si0.20%, Mn 1.53%, P0.011%, S 0.004%, Ni 0.22%, Ti 0.015% V 0.043 %, Mo 0.13%, and the rest are Fe and unavoidable impurities.

[0039] The manufacturing method of the easy-to-weld low yield ratio quenched and tempered oil storage tank steel plate of this embodiment includes: smelting and continuous casting process, heating and rolling process, and heat treatment process;

[0040] (1) Smelting and continuous casting process: molten iron pretreatment, converter smelting, LF refining, RH refining and slab continuous casting. In the smelting process, the content of sulfur and phosphorus in the molten steel is strictly controlled, the desulfurization of molten iron is ≤0.003%, the P of the slab is ≤0.010%, the LF soft blowing time is ≥10 minutes, the target temperature of the continuous casting tundish is 1534-1548℃, and the casting speed is require

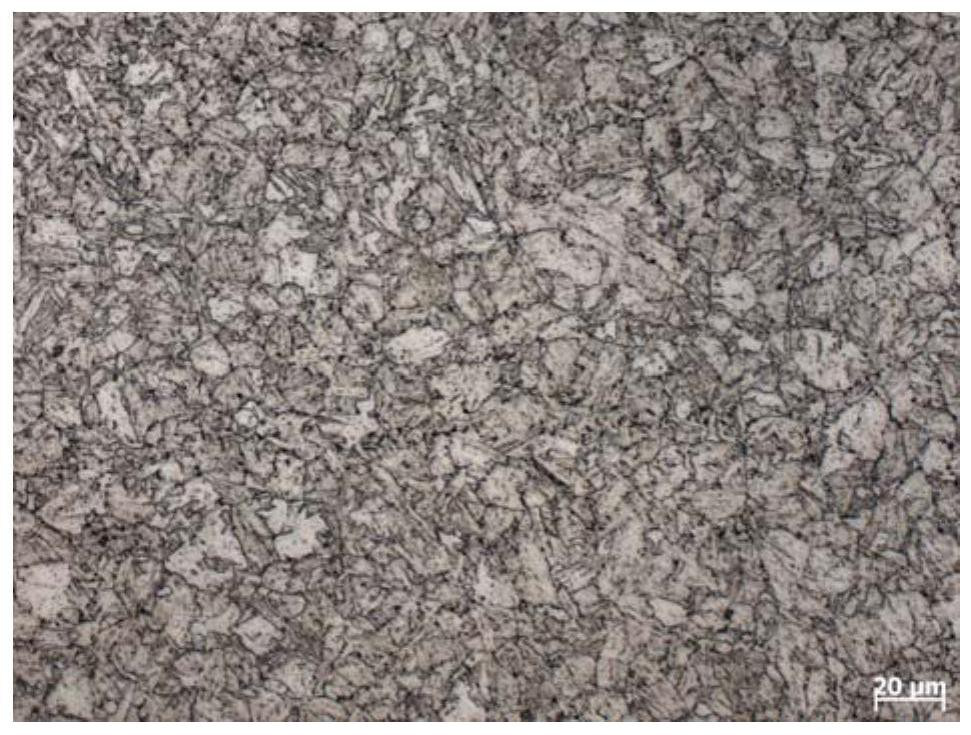

Embodiment 2

[0046] The thickness of the steel plate in this embodiment is 18 mm, and it is composed of the following components in weight percentage: C 0.07%, Si0.20%, Mn 1.55%, P0.011%, S 0.004%, Ni 0.22%, Ti 0.015% V 0.048 %, Mo 0.11%, and the rest are Fe and unavoidable impurities.

[0047] The manufacturing method of the easy-to-weld low yield ratio quenched and tempered oil storage tank steel plate of this embodiment includes: smelting and continuous casting process, heating and rolling process, and heat treatment process;

[0048] (1) Smelting and continuous casting process: molten iron pretreatment, converter smelting, LF refining, RH refining and slab continuous casting. In the smelting process, the content of sulfur and phosphorus in the molten steel is strictly controlled, the desulfurization of molten iron is ≤0.003%, the P of the slab is ≤0.010%, the LF soft blowing time is ≥10 minutes, the target temperature of the continuous casting tundish is 1534-1548℃, and the casting speed

Embodiment 3

[0053] The steel plate of this embodiment has a thickness of 21 mm and is composed of the following components in weight percentage: C 0.08%, Si 0.19%, Mn 1.52%, P 0.009%, S 0.005%, Ni 0.21%, Ti 0.013% V 0.045 %, Mo 0.10%, the rest is Fe and unavoidable impurities.

[0054] The manufacturing method of the easy-to-weld low yield ratio quenched and tempered oil storage tank steel plate of this embodiment includes: smelting and continuous casting process, heating and rolling process, and heat treatment process;

[0055] (1) Smelting and continuous casting process: molten iron pretreatment, converter smelting, LF refining, RH refining and slab continuous casting. In the smelting process, the content of sulfur and phosphorus in the molten steel is strictly controlled, the desulfurization of molten iron is ≤0.003%, the P of the slab is ≤0.010%, the LF soft blowing time is ≥10 minutes, the target temperature of the continuous casting tundish is 1534-1548℃, and the casting speed is requi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap