Discharging device for spraying and drying device

A technology of unloading device and drying device, which is applied to the device, coating, transportation and packaging of surface coating liquid, can solve the problems of prone to accidents, affecting the quality of sprayed surface, troublesome operation, etc., to prevent workpieces. overturning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0024] The applicant believes that after the auto parts are sprayed and dried, because the environment is always in a high temperature, flammable and explosive state, accidents are prone to occur during the manual transfer of the finished products after drying, which is dangerous.

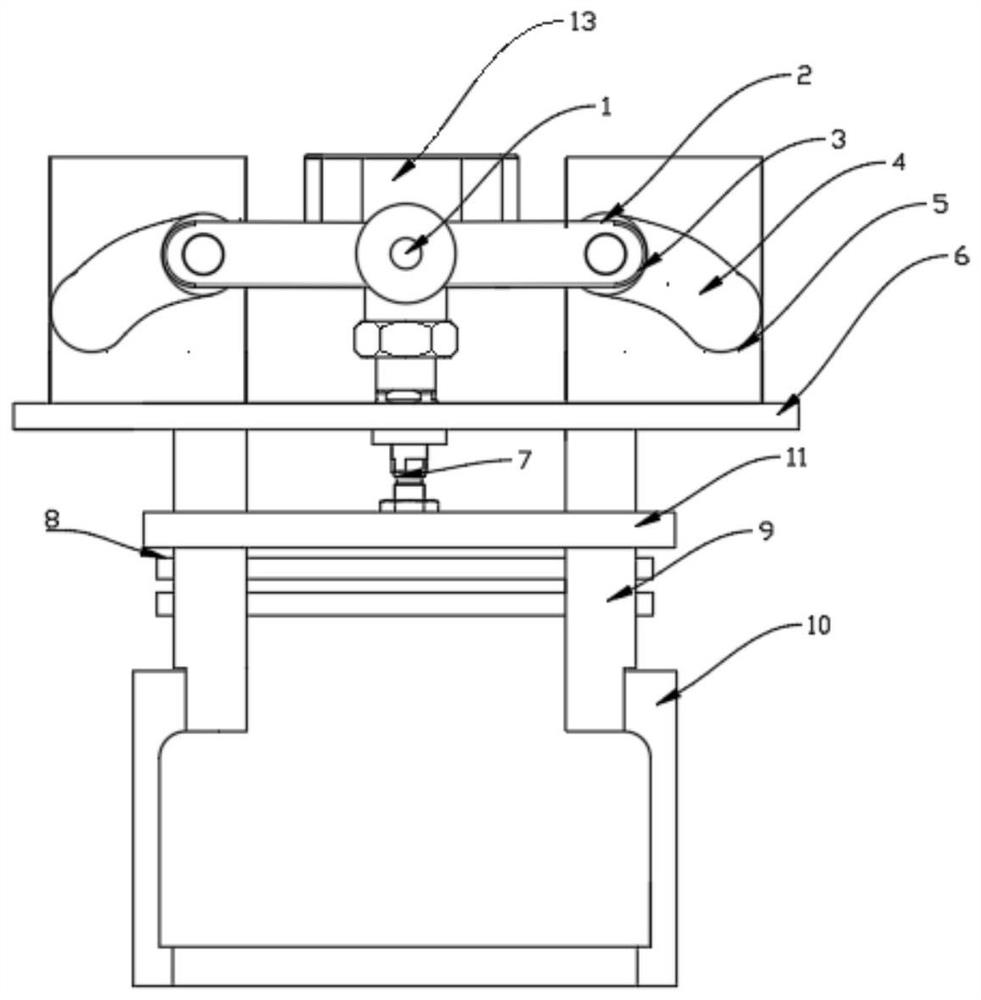

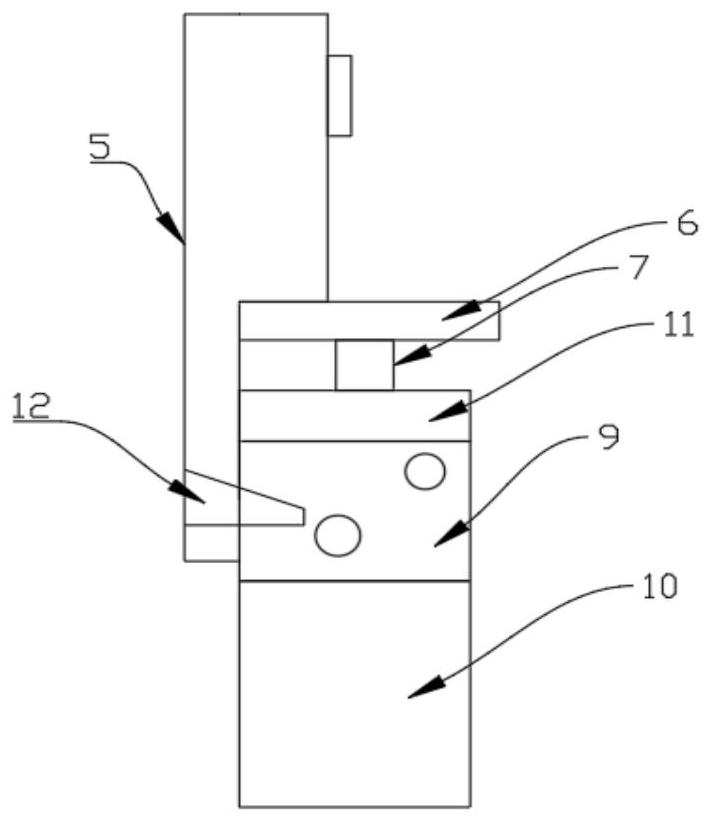

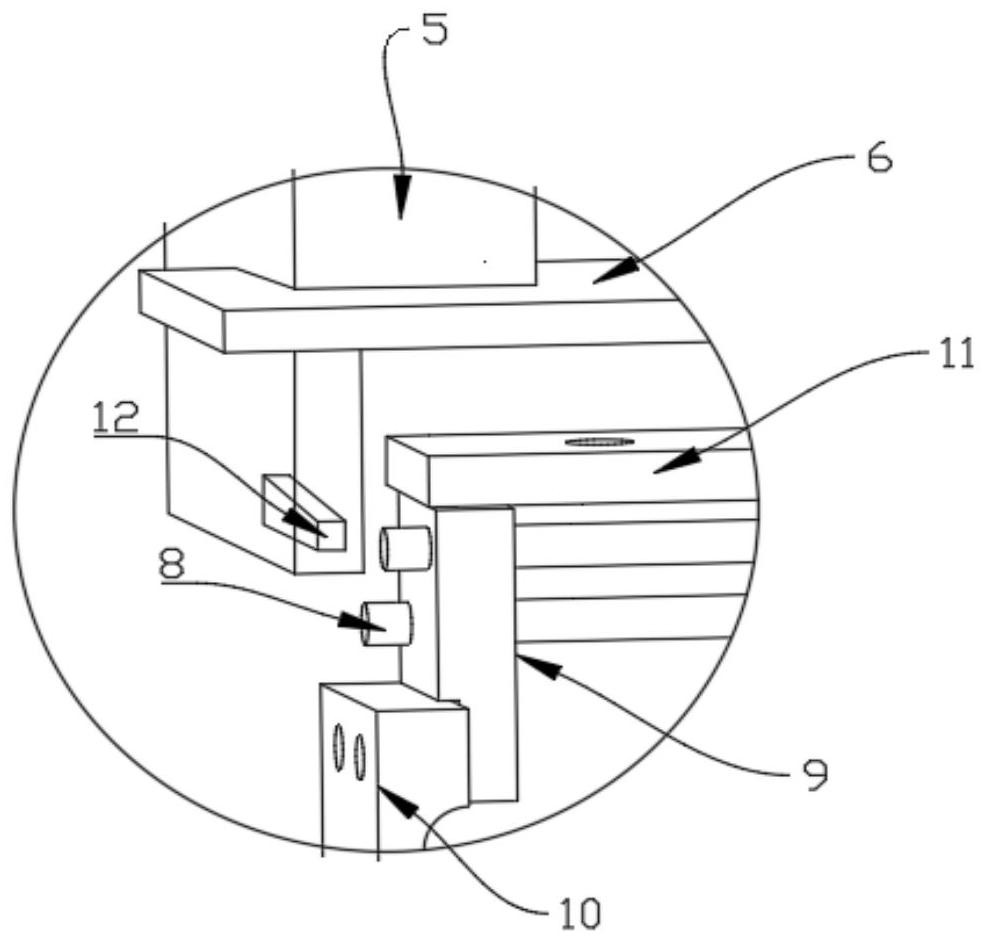

[0025] In order to solve the above-mentioned problems in the prior art, the present invention provides an unloading device for a spray drying device. The unloading device includes three parts: a drying part 13, a telescopic mechanism and a clamping assembly. The specific scheme is as fo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap