Preparation method of flexible glass fiber honeycomb body

A technology for the preparation of a flexible glass fiber honeycomb body, which is applied in the direction of separation methods, chemical instruments and methods, and dispersed particle filtration, which can solve the problems of increased resistance and achieve the effect of improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

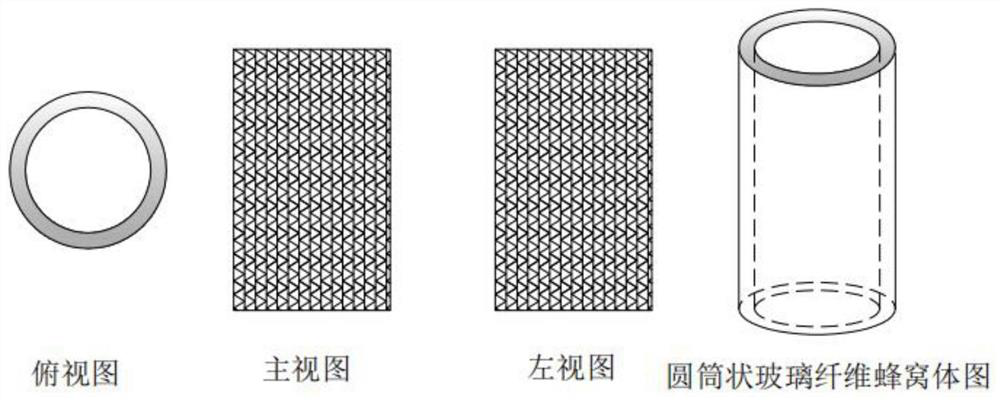

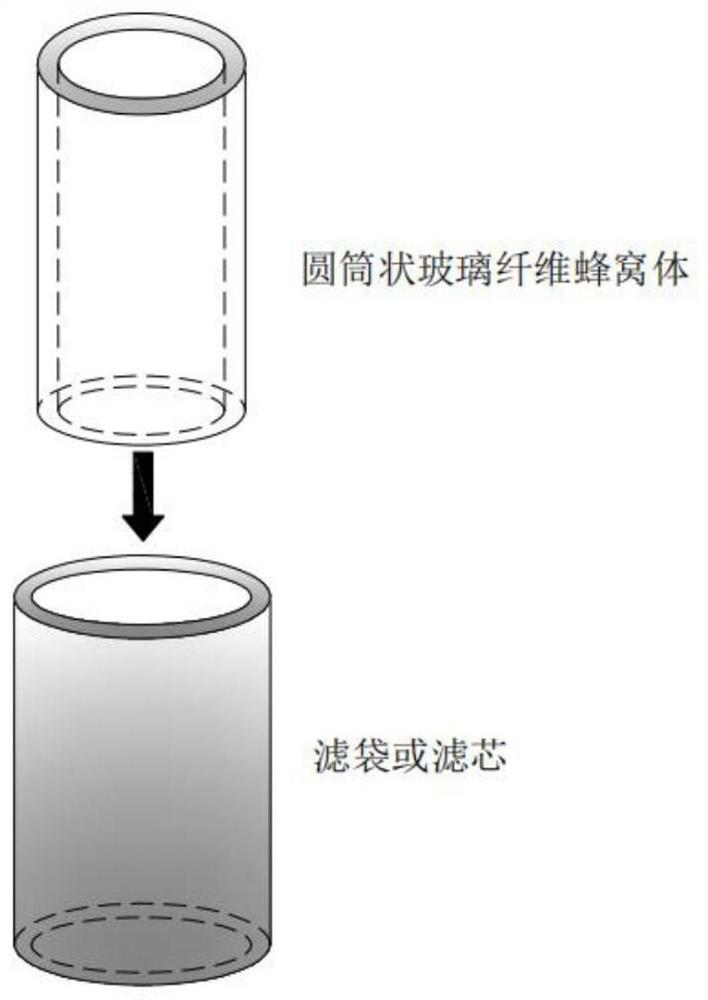

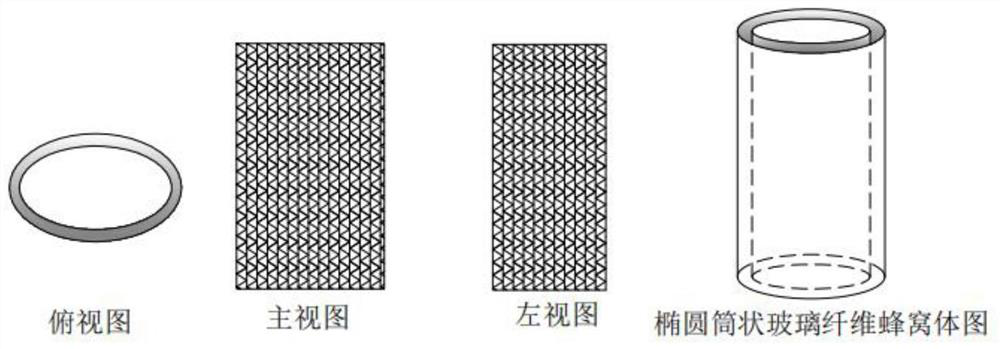

Image

Examples

Embodiment 1

[0042] The preparation method of flexible glass fiber honeycomb specifically comprises the following steps:

[0043] (1) Glass fiber mat corrugation forming

[0044] First immerse the glass fiber mat in the molding solution, then dry it at 100°C for 1 minute, and finally put it into a corrugating machine for molding to obtain a corrugated glass fiber mat;

[0045] Wherein, in terms of mass percentage, the molding solution includes 0.5% of a water-soluble polyester plasticizer, and the balance is water;

[0046] (2) Glass fiber honeycomb assembly molding

[0047] First stack the glass fiber mat and the corrugated glass fiber mat alternately, then immerse in the plastic binder, and finally dry at 50°C for 12 hours, and then at 100°C for 4 hours to obtain a glass fiber honeycomb body;

[0048] Wherein, in terms of mass percentage, the plastic binder includes 30% of water-soluble thermoplastic polyurethane binder (Dolphin-1371 water-based polyurethane resin of Guangzhou Dolphin New

Embodiment 2

[0053] The preparation method of flexible glass fiber honeycomb specifically comprises the following steps:

[0054](1) Glass fiber mat corrugation forming

[0055] First immerse the glass fiber mat in the molding solution, then dry it at 100°C for 4 minutes, and finally put it into a corrugating machine for molding to obtain a corrugated glass fiber mat;

[0056] Wherein, in terms of mass percentage, the molding solution includes 5% of water-soluble polyester plasticizer, and the balance is water;

[0057] (2) Glass fiber honeycomb assembly molding

[0058] Firstly stack the glass fiber mat and the corrugated glass fiber mat alternately, then immerse in the plastic binder, and finally dry at 50°C for 24 hours, and then at 100°C for 8 hours to obtain a glass fiber honeycomb body;

[0059] Wherein, in terms of mass percentage, the plastic binder includes 50% of water-soluble thermoplastic polyurethane binder (Dolphin-1371 water-based polyurethane resin of Guangzhou Dolphin New M

Embodiment 3

[0063] The preparation method of flexible glass fiber honeycomb specifically comprises the following steps:

[0064] (1) Glass fiber mat corrugation forming

[0065] First immerse the glass fiber mat in the molding solution, then dry it at 120°C for 2 minutes, and finally put it into a corrugating machine for molding to obtain a corrugated glass fiber mat;

[0066] Wherein, in terms of mass percentage, the molding liquid includes 2% of water-soluble polyester plasticizer, and the balance is water;

[0067] (2) Glass fiber honeycomb assembly molding

[0068] Firstly stack the glass fiber mat and the corrugated glass fiber mat alternately, then immerse in the plastic binder, and finally dry at 60°C for 18 hours, and then at 110°C for 6 hours to obtain a glass fiber honeycomb body;

[0069] Wherein, in terms of mass percentage, the plastic binder includes 40% of water-soluble thermoplastic polyurethane binder (Dolphin-1371 water-based polyurethane resin of Guangzhou Dolphin New Ma

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap