Flue gas purification equipment for rubber processing

A flue gas purification and rubber technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as the inability of the system to effectively collect dust, affecting the working conditions of workers, and ineffective treatment of smoke and dust, and improve convenience. , Improve the number of small spaces and facilitate interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

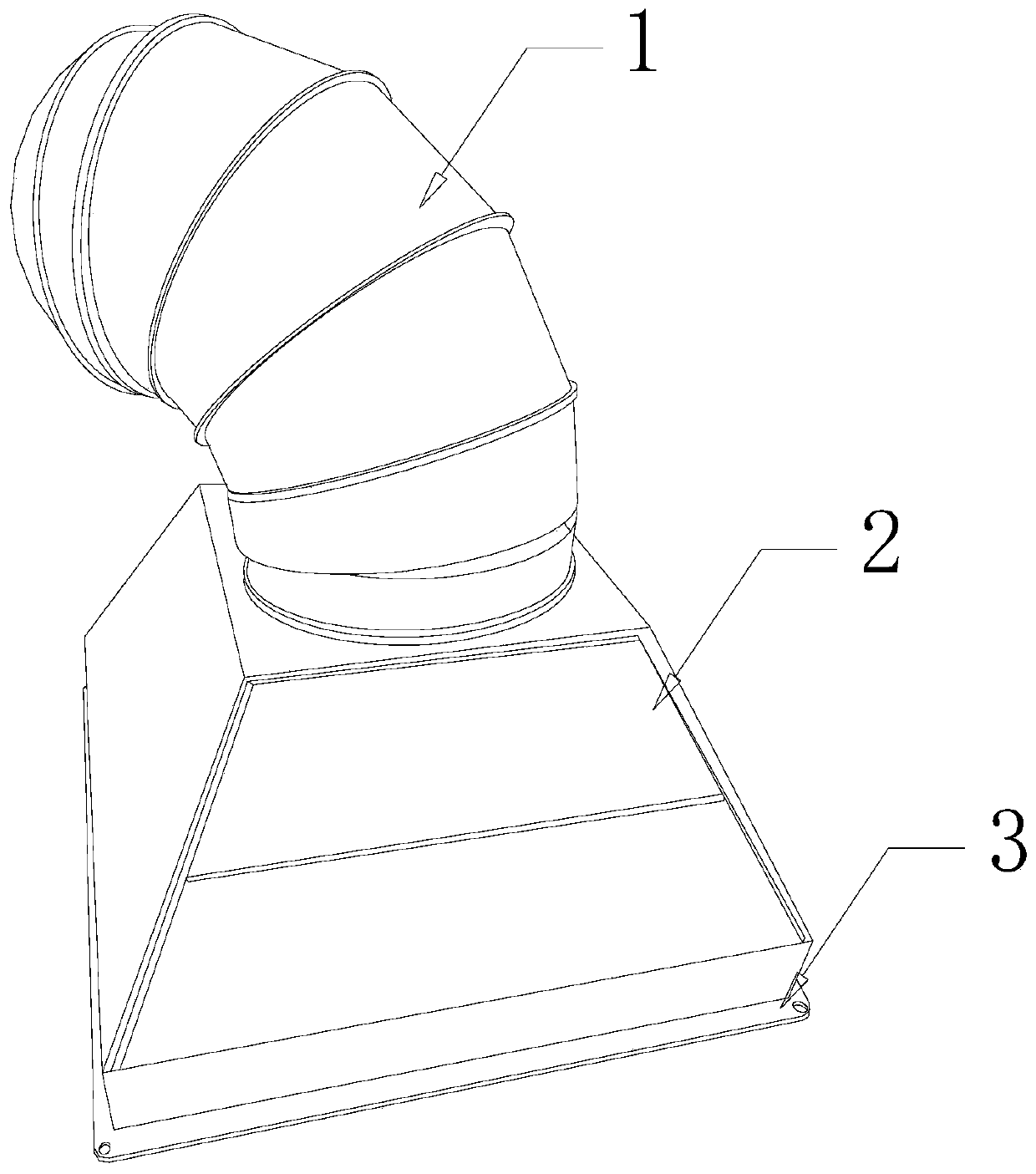

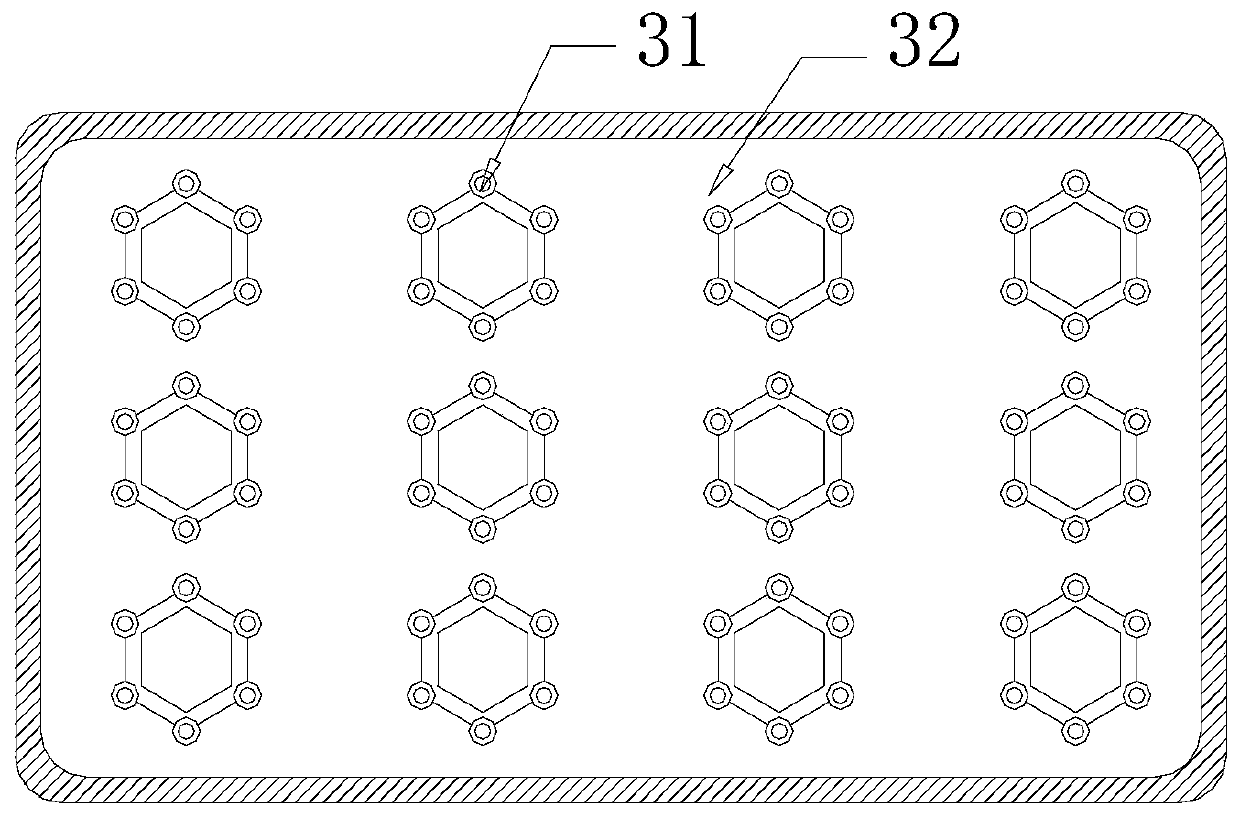

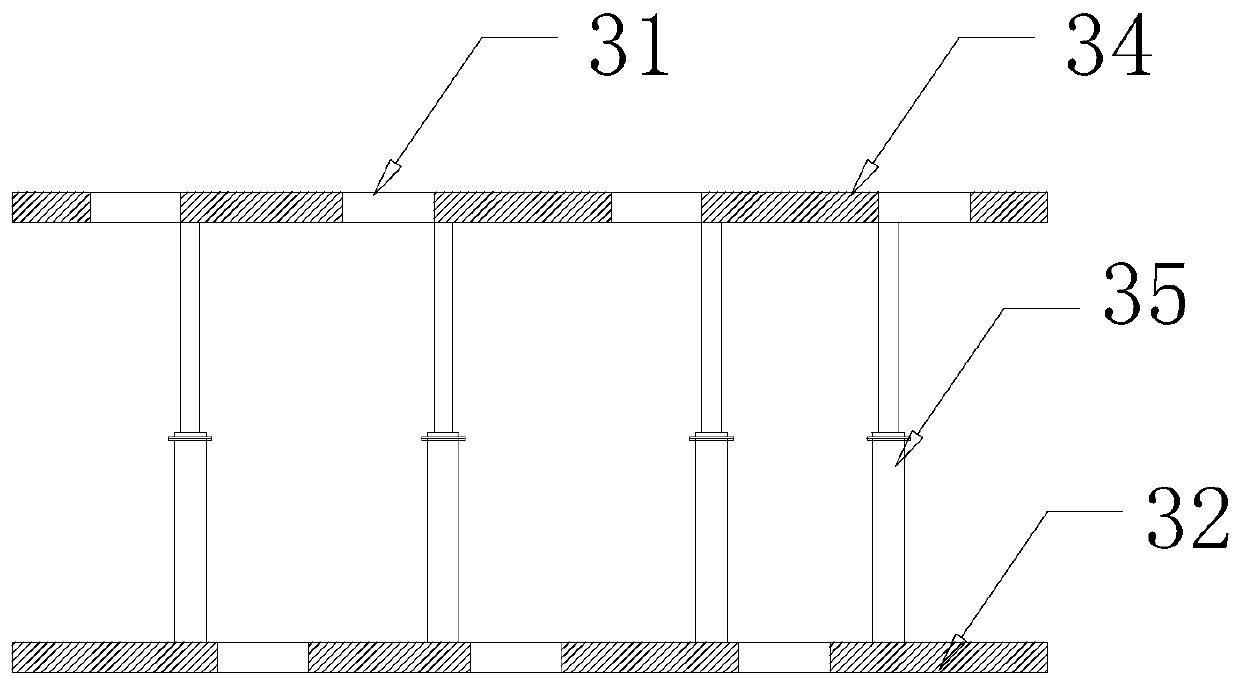

[0029] see Figure 1-Figure 8 , a flue gas purification device for rubber processing. The present invention provides a flue gas purification device for rubber processing. Its structure includes a flow pipe 1, a casing 2, and an adsorption plate 3. A flow pipe 1 is installed on the top of the casing 2 , the bottom of the case 2 is equipped with an adsorption plate 3, the flow pipe 1 and the case 2 communicate with each other, the adsorption plate 3 is provided with a honeycomb 31, a second panel 32, a first panel 34, and a telescopic rod 35, Both the second panel 32 and the first panel 34 are provided with a honeycomb 31 , and a telescopic rod 35 is provided between the second panel 32 and the first panel 34 .

[0030] The honeycombs 31 on the second panel 32 and the first panel 34 are arranged in a staggered manner, which increases the tortuosity of the vertical flow of the flue gas and makes it easier to intercept dust particles in the flue gas.

[0031] The honeycomb 31 is com

Embodiment 2

[0036] see Figure 1-Figure 8 , a flue gas purification device for rubber processing. The present invention provides a flue gas purification device for rubber processing. Its structure includes a flow pipe 1, a casing 2, and an adsorption plate 3. A flow pipe 1 is installed on the top of the casing 2 , the bottom of the case 2 is equipped with an adsorption plate 3, the flow pipe 1 and the case 2 communicate with each other, the adsorption plate 3 is provided with a honeycomb 31, a second panel 32, a first panel 34, and a telescopic rod 35, Both the second panel 32 and the first panel 34 are provided with a honeycomb 31 , and a telescopic rod 35 is provided between the second panel 32 and the first panel 34 .

[0037] The honeycombs 31 on the second panel 32 and the first panel 34 are arranged in a staggered manner, which increases the tortuosity of the vertical flow of the flue gas and makes it easier to intercept dust particles in the flue gas.

[0038] The honeycomb 31 is com

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap