Extrusion device for mechanical part machining

A technology of extrusion device and mechanical parts, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the quality of parts, single extrusion method, displacement of parts, etc., to achieve reasonable structure, simple structure, convenient clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

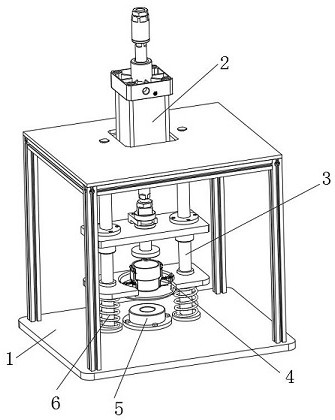

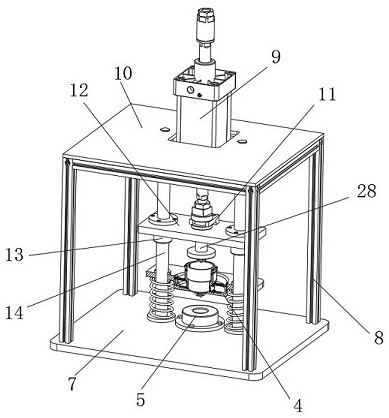

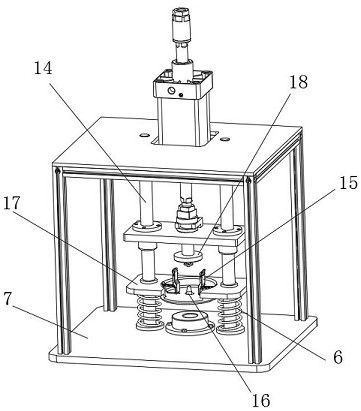

[0030] Example: Reference Figure 1-8 The shown extrusion device for processing mechanical parts includes a frame 1, and also includes a press-fit assembly 2, a guide assembly 3 and a clamping assembly 4, and the guide assembly 3 is used to guide the press-fit assembly 2, such as figure 1 with figure 2 As shown, the bushing sleeve is located at the position of the clamping assembly 4, the clamping assembly 4 is used to clamp and limit the inner and outer sleeves of the bushing, and the press-fit assembly 2 is used to clamp the upper inner and outer sleeves of the bushing on the clamping assembly 4 carry out pressing;

[0031] The upper positioning assembly is installed in the press-fit assembly 2, the lower positioning assembly is installed on the clamping assembly 4, and both the upper positioning assembly and the positioning assembly are used for positioning the multi-bushing inner casing;

[0032] The upper positioning assembly includes a placement groove 29 that is opened

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap