Cooling water circulation system of calcining coke cooler

A technology of circulation system and cold coke machine, applied in the direction of coke cooling, water shower cooler, coke oven, etc., can solve the problems of large water consumption, reduce the quality and output of needle coke, heat waste, etc. effect, reduce the content of water mist, and achieve a high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

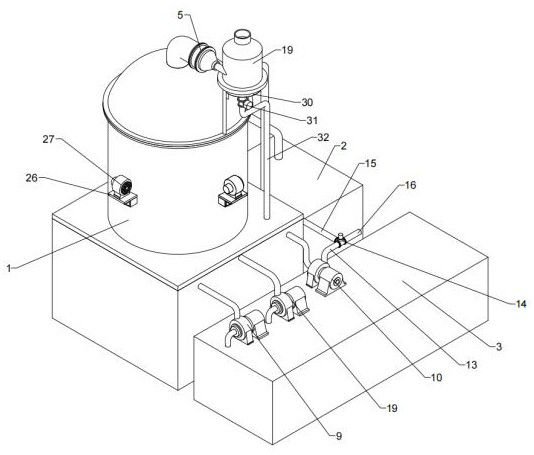

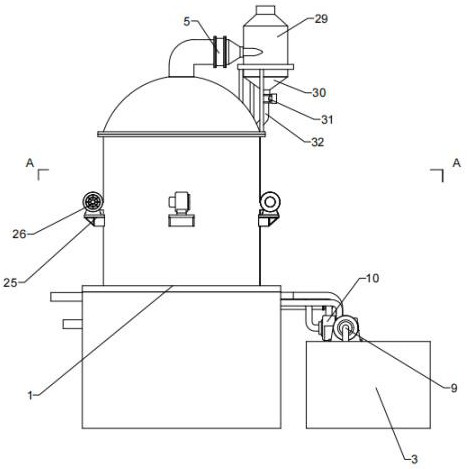

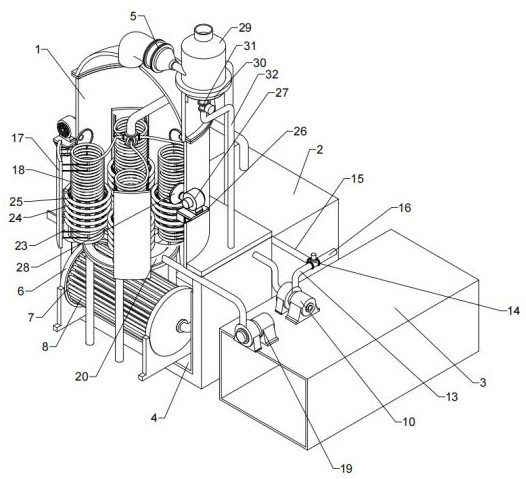

[0027] EXAMPLE: Attached Figure 1-8It can be seen that the present scheme includes a cold water column 1 and a circulating water tank 2, which is disposed on the cold water tank 1 on the cold water tower 1 and is in communication with the backwater of the cold water column 1, and an immersion heat exchange mechanism is provided at the lower portion of the cold water tower 1, immersion The refrigerating end of the heat exchange mechanism is in communication with the circulating water returning pipe, and the upper portion of the immersion heat exchange mechanism is connected to the spray cooling mechanism, and the upper portion of the spray cooling mechanism is connected to the air-cooling and cooling mechanism, the upper end vent position of the cold water column 1 The water mist separation mechanism is provided, and the high temperature circulating water after the heat transfer after the film-type cold circuit is introduced into the immersion heat exchange mechanism, and the high tem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap