Buried anti-floating water tank with bottom plate

A buried, water tank technology, applied in water supply devices, water saving, configuration of water supply pools, etc., can solve the problems of poor anti-floating effect of water tanks, easily polluted water quality, long construction period, etc., and achieve good anti-floating ability. , Excellent anti-floating performance, simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

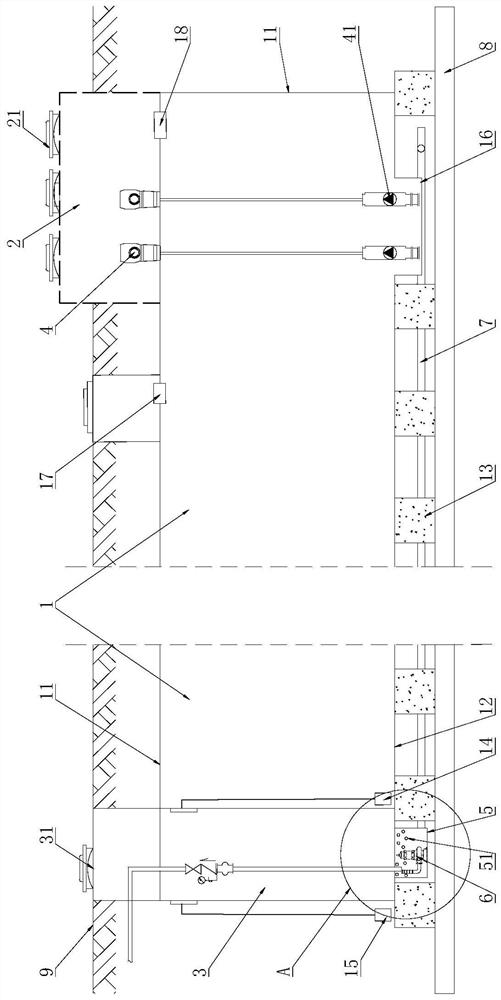

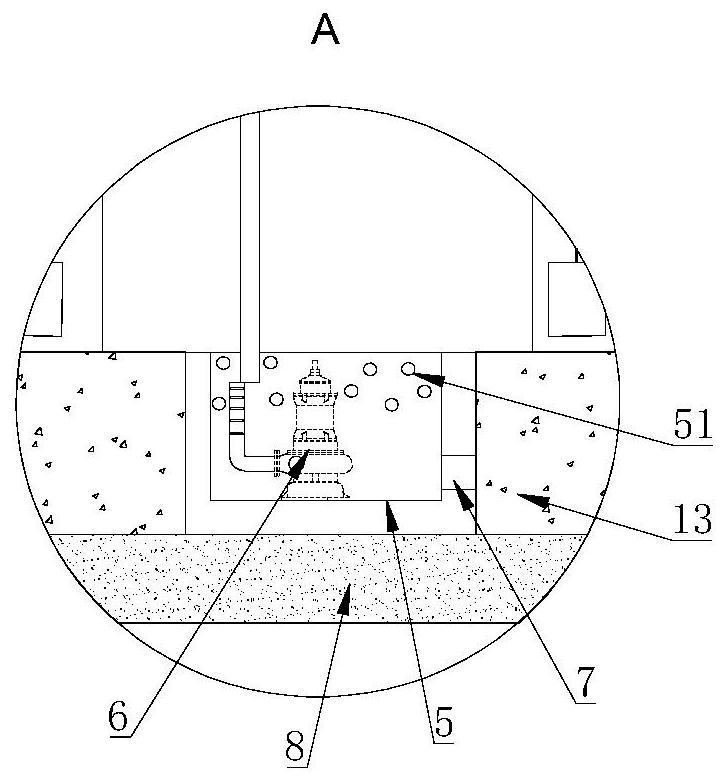

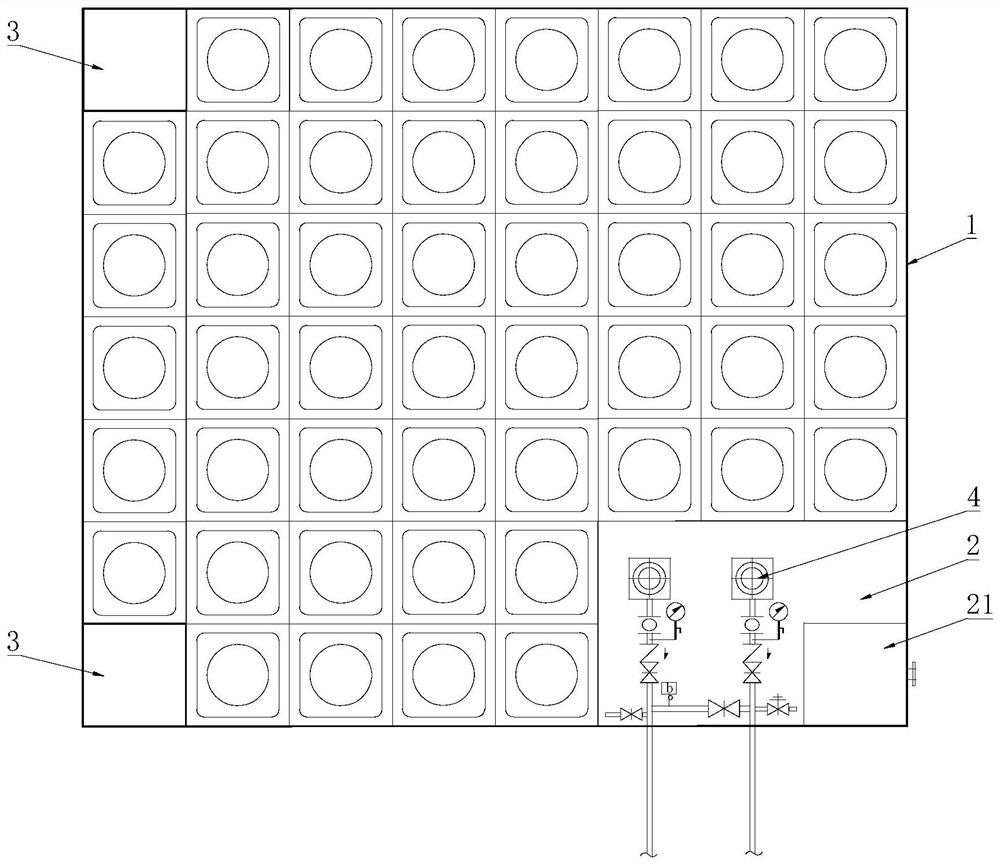

[0029] Such as figure 1 As shown, the buried anti-floating water tank with a floor provided by the present invention includes a water tank 1 , a pump room 2 and a drainage bin 3 . Wherein, the water tank 1 includes a square box body 11 spliced by a plurality of integrally stamped metal molded plates, and a bottom plate 12 connected with the box body 11 . The inside of the box body 11 is provided with multiple groups of criss-cross metal profiles to reinforce the box wall and improve the structural strength of the box body. The inside and the outside of the water tank 1 are respectively equipped with a liquid level monitor 14 in the tank and a liquid level monitor 15 outside the tank. Such as figure 1 As shown, the pump room 2 is arranged at the top of the tank 11, and the pump room 2 is provided with an in-tank pump 4 for pumping the water stored in the water tank 1. The bottom of the water tank 1 is provided with a sump 16 in the tank, the bottom of the sump 16 in the tank

Embodiment 2

[0036] The buried anti-floating water tank with bottom plate provided by this embodiment has the same basic structure as that of Embodiment 1, except that: Figure 5 As shown, the pump room 2 is arranged on the horizontal side of the box body 11, the pump 4 in the water tank is arranged on the bottom floor of the pump room 2, and the floor of the pump room 2 is on the same level as the bottom plate 12 of the water tank 1. The suction pipe of the pump 4 in the water tank runs through the side wall of the casing 11 and the pump head 41 is stretched into the bottom of the sump 16 in the casing, so as to draw the stored water inside the water tank 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap