Method for preparing porous carbon coated transition metal oxide material through CTAB regulation and control and application

A transition metal, coating material technology, applied in electrochemical generators, structural parts, electrical components, etc., can solve the problems of many processes, affecting the mass production of porous materials, complex reagents, etc., to improve transmission efficiency, excellent cycle stability The effect of convenience and convenience in the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

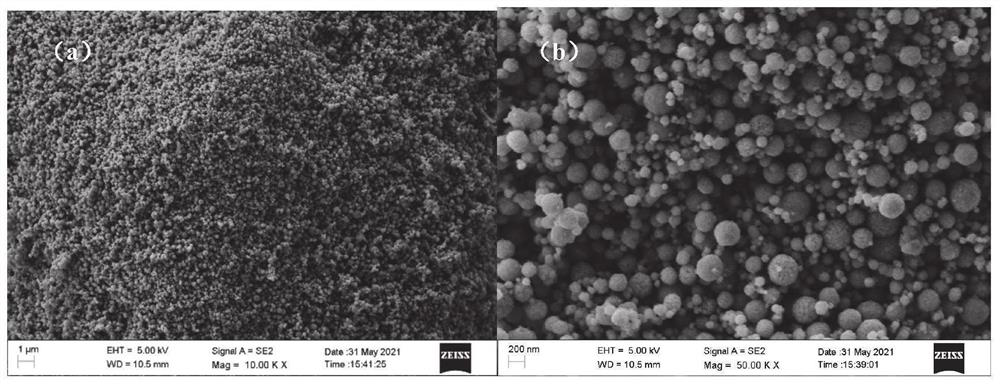

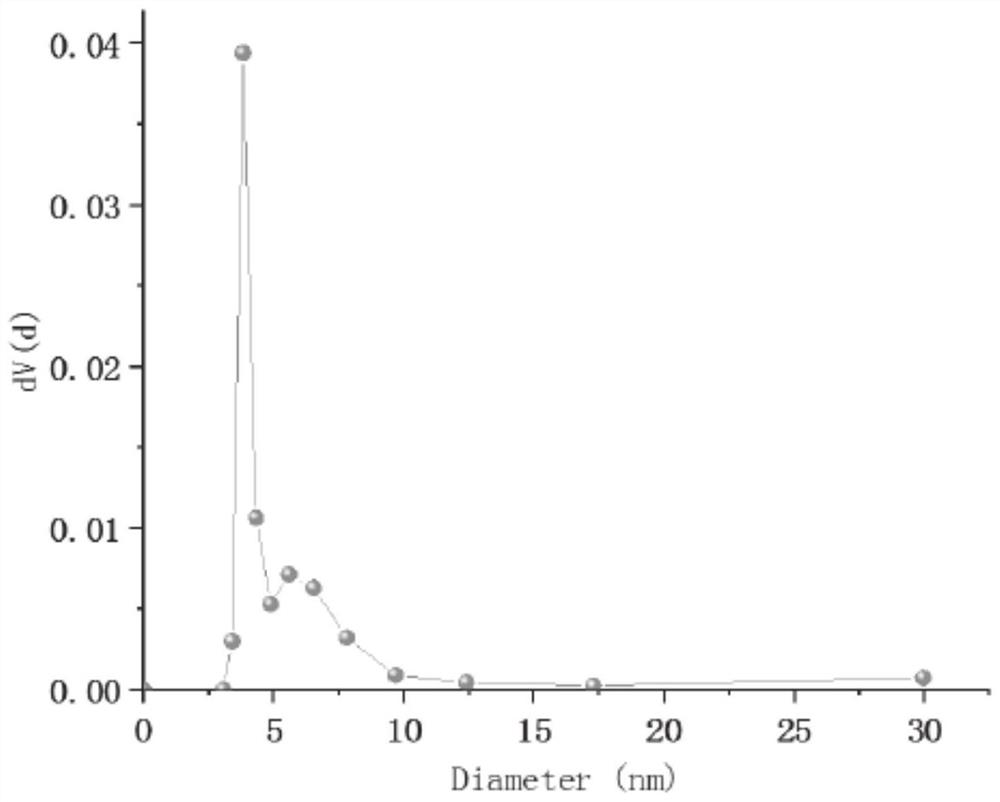

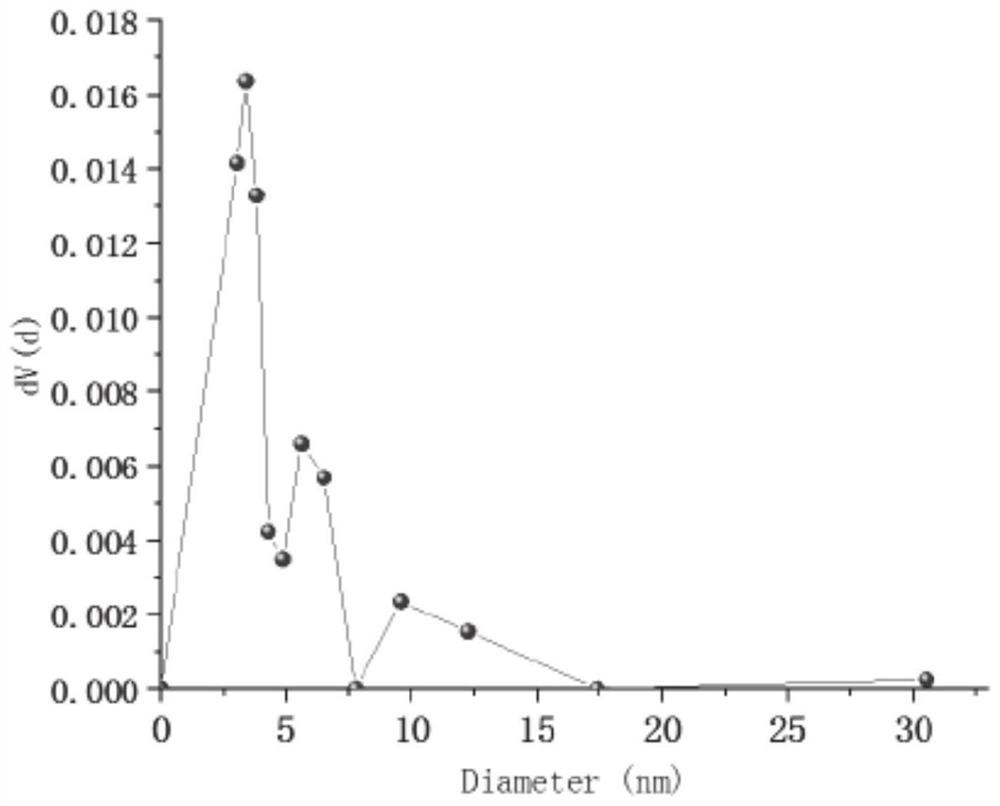

Image

Examples

Example Embodiment

[0050] Example 1

[0051] A process for preparing a porous carbon coating methods using CTAB regulatory transition metal oxide material, comprising the steps of:

[0052] (1) Take 1.2114g (10mmol) of Tris (C 4 Hide 11 NO 3 , Tris) in 1000mL of deionized water, which was magnetically stirred until complete dissolution, then adjusted to PH 8.5 with concentrated hydrochloric acid, i.e., Tris buffer solution was obtained.

[0053] (2) were taken 0.5g Fe 3 O 4 Dopamine hydrochloride and 0.5g and 0.2g of cetyl trimethyl ammonium bromide (C 19 Hide 42 BrN, CTAB) ultrasonic dispersion prepared in Tris buffer solution (1) in a 250mL, stirred at room temperature for 12h, allowed to stand and centrifuged to give a black precipitate from ethanol, deionized water, and dried in vacuo 12h 60 ℃, cooled to dopamine coated after the room temperature to obtain a modified CTAB Fe 3 O 4 (Fe 3 O 4 @ PDA-CTAB).

[0054] (3) Take 0.5g (2) Fe prepared in 3 O 4 @ PDA-CTAB, in an argon atmosphere, was heated

Example Embodiment

[0055] Example 2

[0056] A process for preparing a porous carbon coating methods using CTAB regulatory transition metal oxide material, comprising the steps of:

[0057] (1) Take 1.2114g (10mmol) of Tris (C 4 Hide 11 NO 3 , Tris) in 1000mL of deionized water, which was magnetically stirred until complete dissolution, then adjusted to PH 8.5 with concentrated hydrochloric acid, i.e., Tris buffer solution was obtained.

[0058] (2) were taken 0.5g Fe 3 O 4 And dopamine hydrochloride 0.5g and 0.25g cetyl trimethyl ammonium bromide (C 19 Hide 42 BrN, CTAB) ultrasonic dispersion prepared in Tris buffer solution (1) in a 250mL, stirred at room temperature for 12h, allowed to stand and centrifuged to give a black precipitate from ethanol, deionized water, and dried in vacuo 12h 60 ℃, cooled to dopamine coated after the room temperature to obtain a modified CTAB Fe 3 O 4 (Fe 3 O 4 @ PDA-CTAB).

[0059] (3) Take 0.5g (2) Fe prepared in 3 O 4 @ PDA-CTAB, in an argon atmosphere, was heated 550

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap