Preparation method of bionic carbon negative electrode material used as potassium ion battery negative electrode, and product

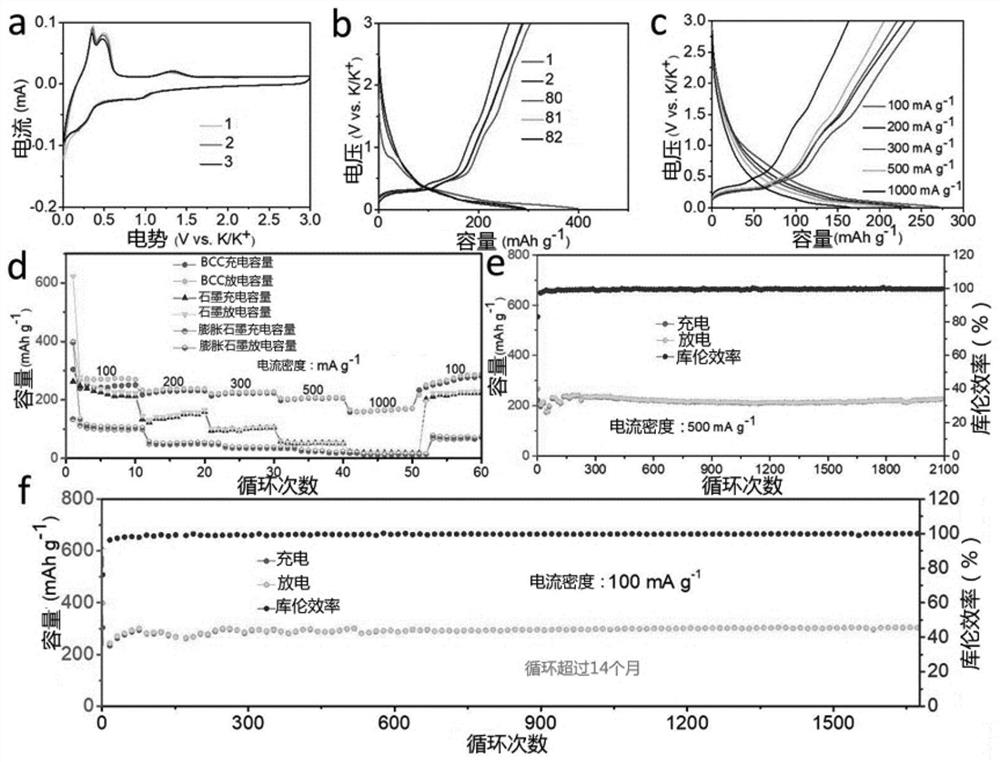

A negative electrode material and battery negative electrode technology, applied in the field of biomimetic carbon and its preparation, can solve the problems of insufficient rate performance and fast charge/discharge characteristics, and achieve excellent electrochemical performance, high reversible capacity, and excellent rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041]Example 1

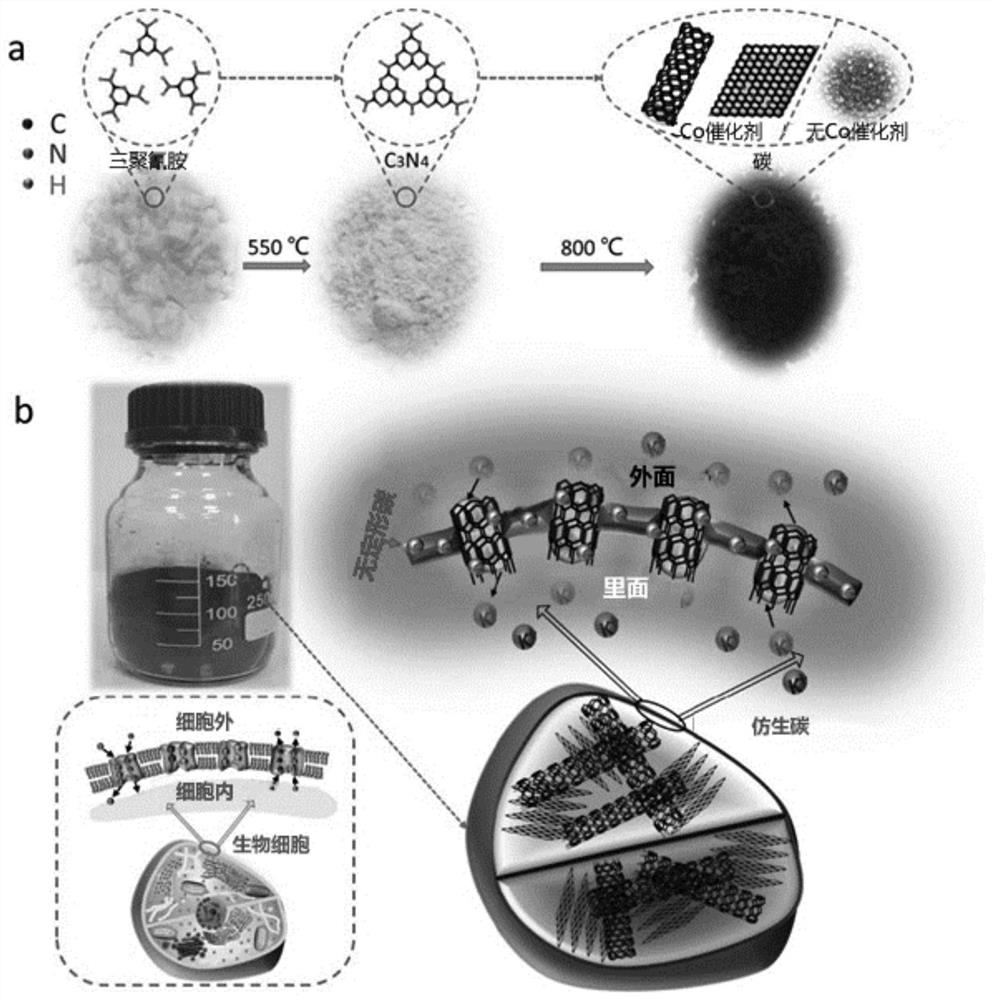

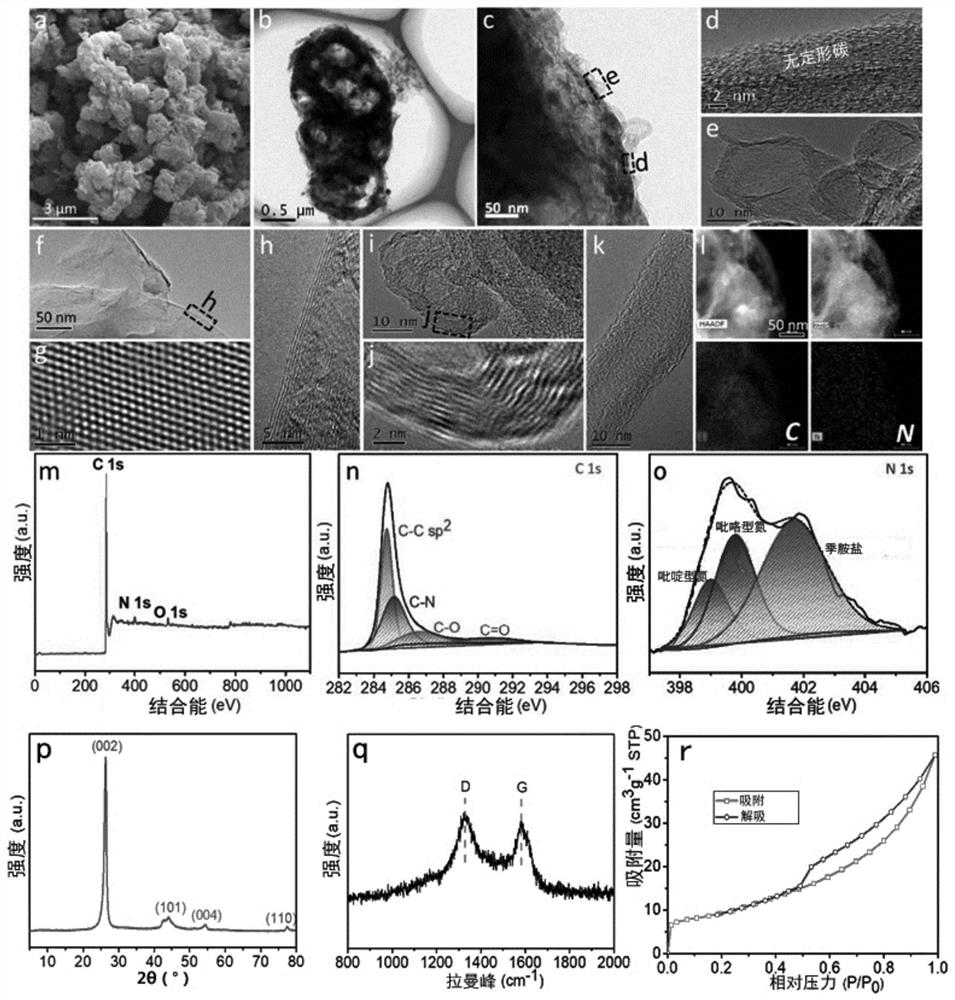

[0042]Such asfigure 1 As shown, first of all, a nitrogen-carbon compound (C3N4) Intermediate: Put 15mg of melamine precursor in a porcelain boat and put it in a muffle tube furnace at 2℃min-1The heating rate is heated to 550°C and kept at a constant temperature for 5 hours, and then naturally cooled to room temperature to obtain C3N4;

[0043]Secondly, cobalt (Co) catalyst catalyzes high-temperature carbonization treatment: Use an agate mortar to remove C3N4Grind into fine powder, then mix with metal Co at a mass ratio of 1:1, and then mix thoroughly in an agate mortar; put it in a porcelain boat after mixing evenly, and heat it at 2℃ in a tube furnace with an argon atmosphere min-1The rate of heating up to 800 ℃, and constant temperature heating treatment at this temperature for 2h, and then natural cooling to room temperature;

[0044]Finally, acid treatment to remove the metal catalyst; repeated washing with 2mol / L hydrochloric acid (HCl) solution to remove Co, and then r

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap