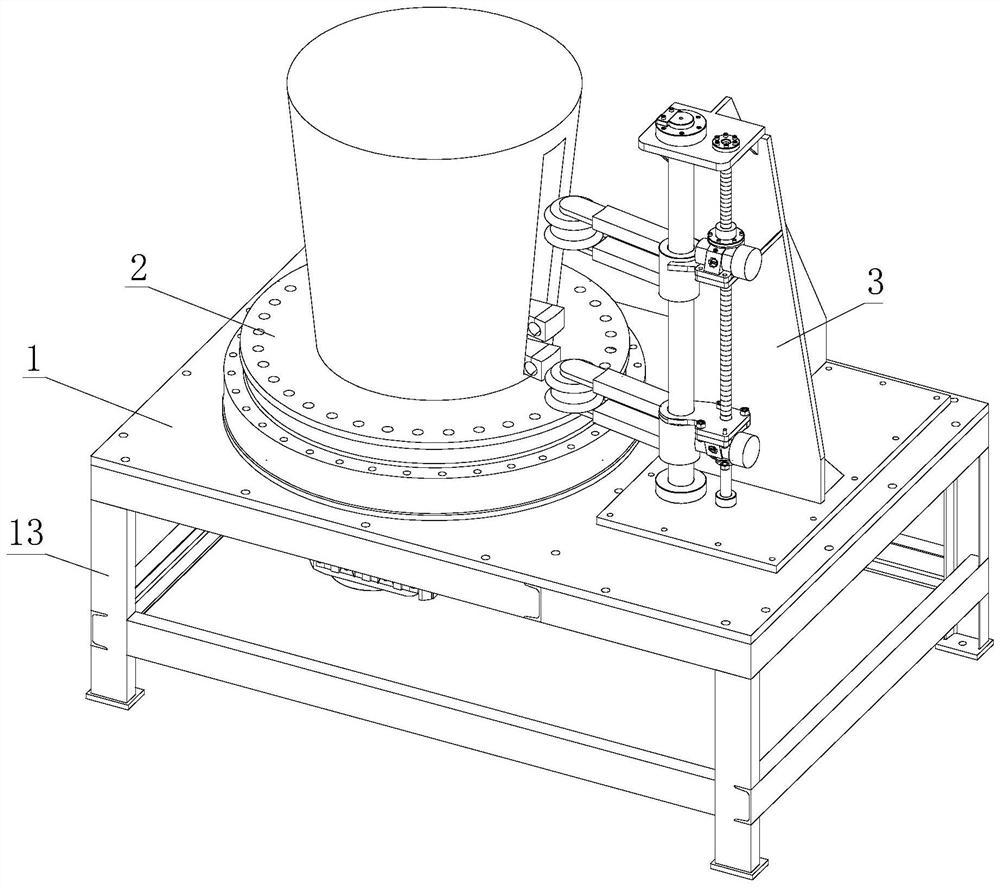

Large-sleeve pipe bending equipment and implementation method thereof

A technology of pipe bending equipment and large sets, which is applied in the field of large sets of pipe bending equipment, can solve the problems of bending equipment without adjusting the spiral spacing, and spiral bending of U-shaped pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] An implementation method of a large set of pipe bending equipment, comprising the following steps:

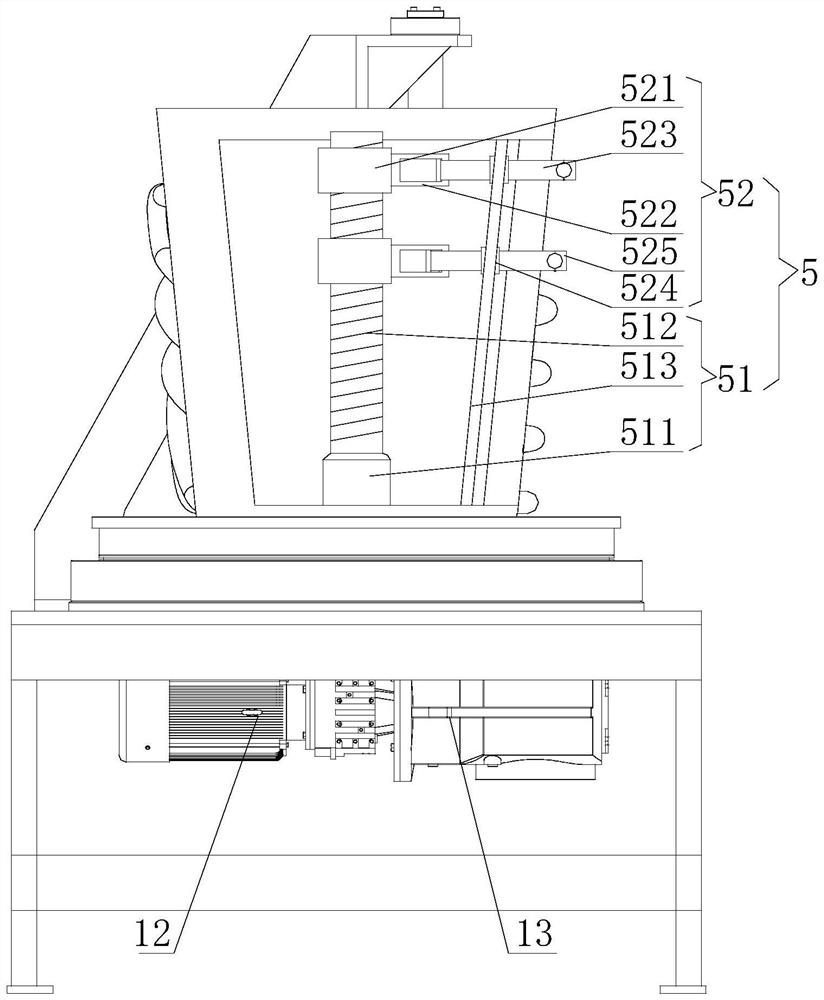

[0045] Step 1: The motor 511 drives the first screw rod 512 to rotate, the locking assembly 52 moves to the bottom end along the first screw rod 512, the air pump 71 pumps air into the cavity of the outer pillar 72, the inner pillar 73 and the guide wheel 74 shrink Back in the outer pillar 72;

[0046] Step 2: Open the locking cover 525, insert the two ends of the U-shaped tube into the arc groove of the port of the locking rod 523, turn over the locking cover 525 to lock the tube, and the tube is stuck in the guide wheel 74;

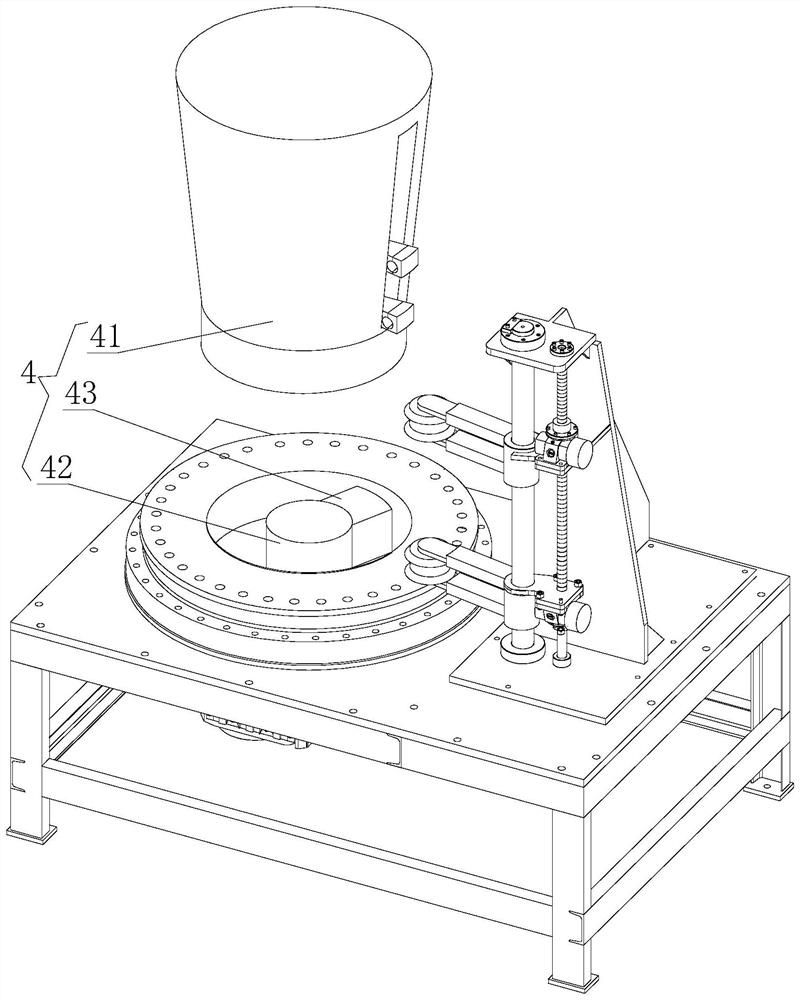

[0047] Step 3: The motor 11 drives the membrane 41 to rotate after the speed is reduced by the reducer 12, the motor 511 drives the first screw 512 to rotate, and the tube is bent around the membrane 41;

[0048] Step 4: When the tube body is bent 90° around the membrane 41, the pneumatic pump 71 injects air into the cavity of the outer pillar 72...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap