Resource utilization method of dehydrated and desilted bottom mud

A resource utilization and bottom sludge technology, applied in chemical instruments and methods, dehydration/drying/thickened sludge treatment, solid waste removal, etc., can solve problems such as environmental pollution, large site occupation, and high land occupation pressure of dredging projects , to alleviate the shortage of river sand resources and clay resources, widely used in the market, and achieve high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

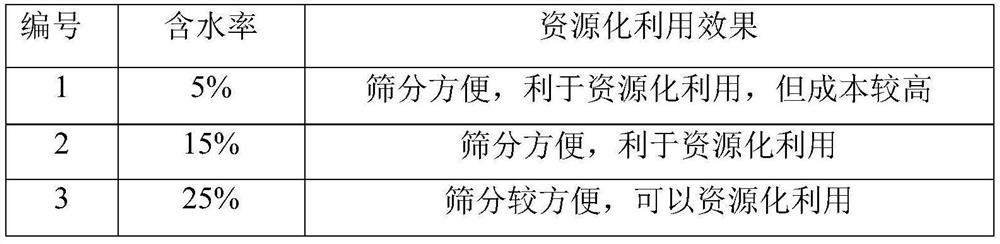

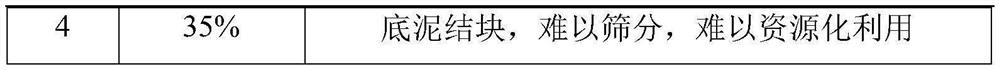

[0035]A method for resource utilization of dewatered dredged bottom sludge, comprising the following steps:

[0036] (1) Drying the dewatered dredged bottom sludge to obtain dried dredged bottom sludge with a water content of 19%.

[0037] (2) pulverize the dried dredging bottom mud obtained in step (1) until the particle size≤1.0mm, sieve, and screen out particles of different particle sizes;

[0038] (3) Carry out harmless treatment to the particles with a particle size <0.075mm screened out in step (2), and the resulting product is used as clay raw material for preparing clay bricks, pottery, cement or crystal soil; meanwhile, the step obtained ( 2) The particles with a particle size of 0.075 mm to 1.0 mm screened out are subjected to sand washing treatment, and the obtained products are used as sand and gravel raw materials for construction sand, and the resource utilization of dewatered dredging sediment is completed.

[0039] In the present invention, particles with a part

Embodiment 2

[0047] A method for resource utilization of dewatered dredged bottom sludge is basically the same as that of Example 1, the only difference being that in Example 2, in step (1), the dried dredged bottom sludge with a water content of 10% is used. Simultaneously, the drying method of the dried dredging bottom mud with a moisture content of 10% in Example 2 is also basically the same as Example 1, the only difference is that in Example 2, the ventilation wall is carried out under high temperature and dry climate conditions. Air dry, and the air drying time is 3 days.

[0048] In this example, after reducing the moisture content of the dewatered dredged sludge by 10%, the obtained dried dredged sludge can be crushed and sieved to make particles of different particle sizes, which can be used as clay raw materials for the preparation of Clay bricks, ceramics, cement or crystal soil, and as sand and gravel raw materials, used for construction sand, so as to realize the resource utiliza

Embodiment 3

[0050] A method for resource utilization of dewatered dredged bottom sludge is basically the same as that of Example 1, the only difference being that in Example 3, in step (1), the dried dredged bottom sludge with a water content of 19% is used. Simultaneously, the dried dredging bottom sludge with a moisture content of 19% in Example 3 was prepared by heating and drying.

[0051] In Example 3, the dried dredging bottom mud with a moisture content of 19% is obtained by heating and drying, that is, drying in a drying oven for 12 hours:

[0052] In this example, the water content of the dewatered dredged sludge is reduced by 10%, and the obtained dried dredged sludge can be crushed and sieved to make particles of different particle sizes, which can be used as clay raw materials for the preparation of clay Bricks, ceramics, cement or crystal soil, as well as sand and gravel raw materials, used for construction sand, so as to realize the resource utilization of dewatered dredging se

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap