Electrode inhibitor and application thereof, and production method of battery pole piece

A battery pole piece and inhibitor technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as pole piece cracking, and achieve the effects of improving adhesion, smooth appearance, and inhibiting pole piece cracking problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] When the battery inhibitor of the present invention is used for the positive pole piece of the battery, the preparation method of the battery pole piece may further comprise the steps:

[0028] S1. Dissolve PVDF (polyvinylidene fluoride) in a solvent to form a first glue solution, then add electrode inhibitors to the first glue solution, and mix evenly to form a second glue solution.

[0029] According to the choice of PVDF, the solvent uses N-methylpyrrolidone (NMP).

[0030] S2. After adding a conductive agent and an active material to the second glue solution, disperse at a high speed to form a uniform and stable slurry.

[0031] The speed of high-speed dispersion can be selected from 1500r / min-4000r / min.

[0032] The corresponding pole piece is a positive pole piece, and the active material can be nickel-cobalt lithium manganese oxide, lithium manganese oxide, lithium cobalt oxide, lithium iron phosphate, etc., which can be realized by the existing technology.

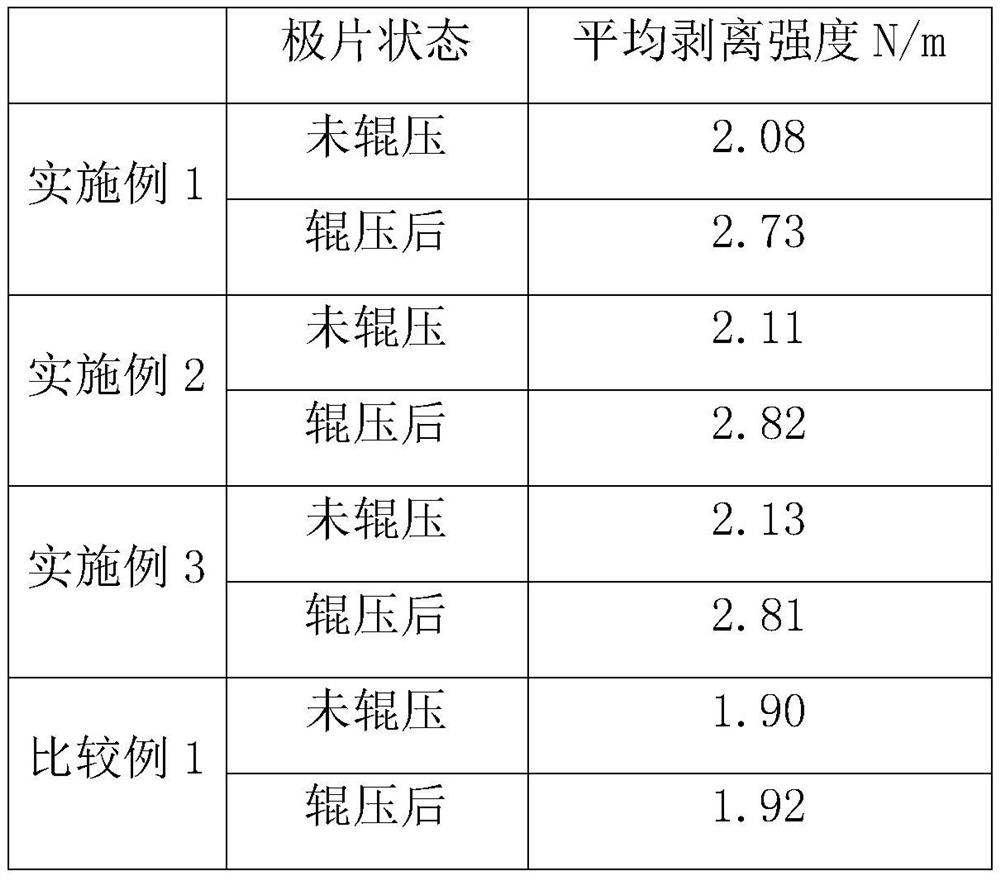

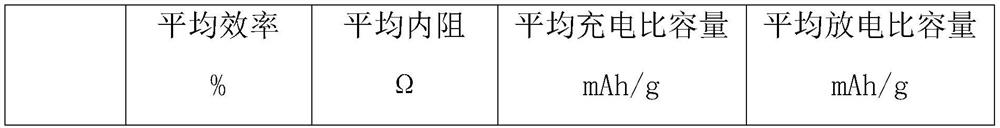

Embodiment 1

[0048] Take active material (LFP): SP (conductive carbon black): PVDF: electrode inhibitor = 92.52:4:3:0.48 as an example:

[0049] First use NMP to prepare 30g of PVDF glue with a solid content of 5%, add 0.82g of electrode inhibitor and stir to form a uniform glue; successively weigh 2.01g of SP and 46.5g of LFP, add 27.6g of NMP, and disperse at a high speed (2000r / min) 15 minutes to mix evenly to obtain a slurry with a solid content of 47.0%; use the coating equipment to coat the slurry on the surface of the aluminum foil, and dry the solvent at 105°C to obtain the pole piece; Get a lithium-ion battery.

Embodiment 2

[0051] Take LCO (lithium cobaltate):SP:PVDF:electrode inhibitor=97.46:1:1.3:0.24 as an example:

[0052] First prepare 13g of PVDF glue with a solid content of 5% with NMP, add 0.4g of electrode inhibitor and stir to form a uniform solution; weigh 0.5g of SP and 48.85g of LCO successively, add 11.0g of NMP, and disperse at a high speed (2000r / min) Mix evenly for 15 minutes to obtain a slurry with a solid content of 68.0%. The slurry is coated on the surface of aluminum foil with coating equipment, and the solvent is dried at 105°C to obtain a pole piece; a lithium-ion battery is obtained through sheet production, assembly, chemical formation, and capacity separation.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap