Drying equipment for metal product machining

A technology for drying equipment and metal products, applied in lighting and heating equipment, drying solid materials, drying goods handling, etc. Achieve the effect of improving drying treatment effect, wide and uniform drying level, and increasing drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

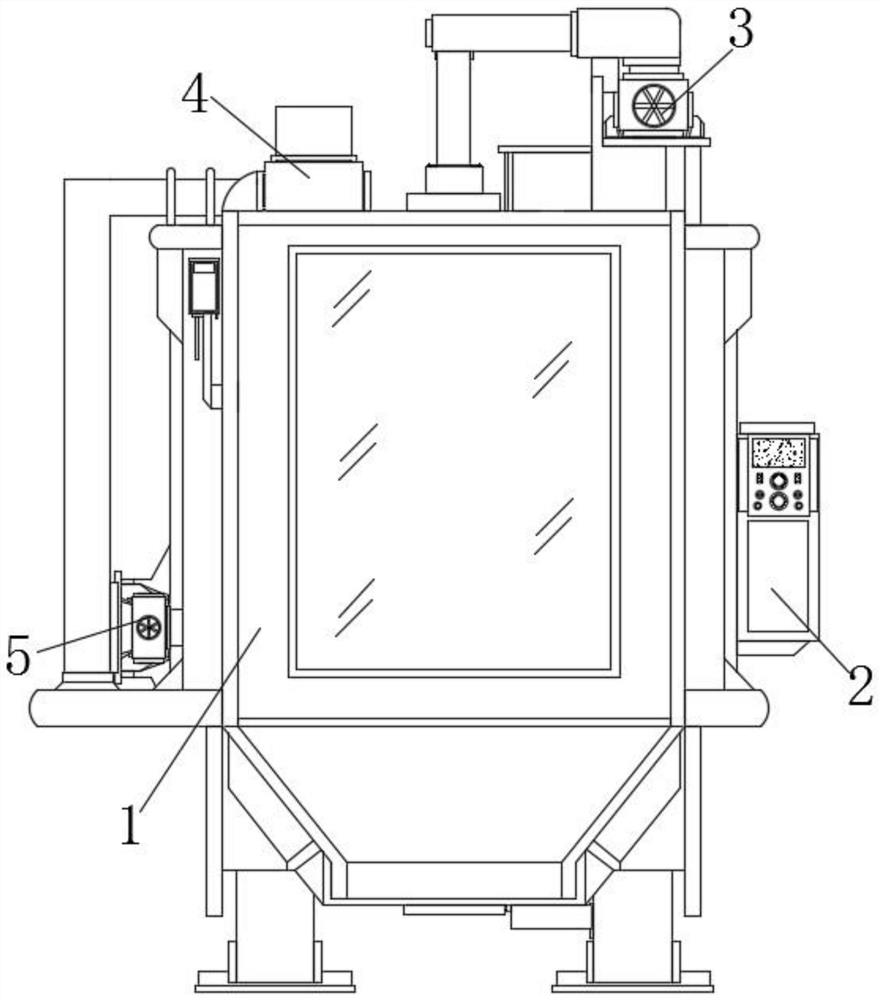

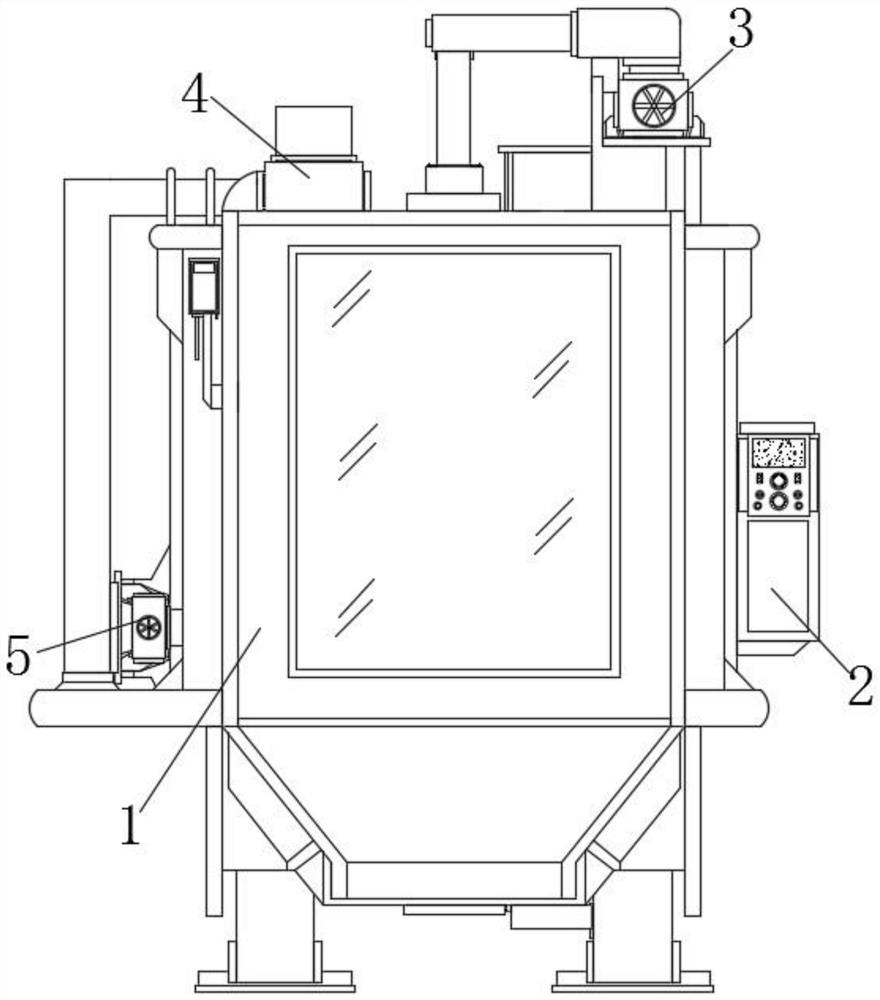

[0034] Example 1, such as Figure 1-2 As shown, when the temperature in the body 1 is perceived by the temperature monitoring system 52, when the specified index is perceived, the negative pressure fan 53 can be taken automatically in the communication of the conduit 54, and forced the negative pressure fan 53. The feed port 4 is introduced into the feed port 4 by the guide flow of the circulation conduit 51, so that the metal article falling into the feed port 4 is preheated, which not only improves the subsequent heating and drying efficiency of the metal article, but also in part of the gas reflow body 1, Another part of the gas is directly in contact with external air, increasing the flexibility and convenience of the temperature control.

Embodiment 2

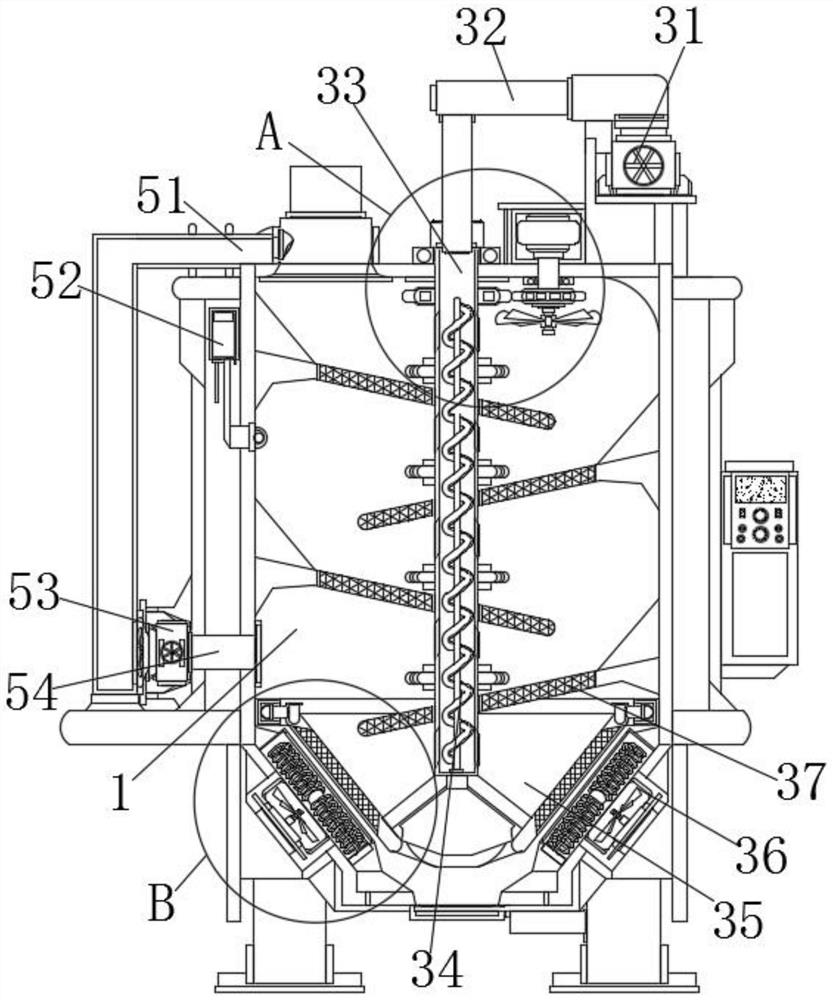

[0035] Example 2, such as Figure 2-4 As shown, when the metal article rolls into the inner side wall of the tapered groove 35, the inside and outside sidewalls of the tapered groove 35 can be heated in advance by the activation of the electric heating tube 363, and the electric heating tube 363 is promoted by the formation of the fan 362. The formed hot gas is more rapidly drawn upward. At this time, not only improve the water stains of the inner side wall of the tapered groove 35 contact the metal article, and the heat gland 31 and the heating gas of the electric heating tube 363 are mixed with each other, and flow in the device It is facilitated that the metal article has a wider contact surface under the flow of hot gas, and the drying efficiency is better.

[0036] Working Principle: When the device is used, first control the hot air set 31 and the electric heating tube 363 as the heating system by the controller 2, and then introduced from the feed port 4 from the feed port 4, d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap