Automatic battery tail glue sticking and corner pressing machine

A technology of crimping machine and battery, applied in primary battery, battery assembly machine, equipment for manufacturing primary battery, etc., can solve the problems of low production efficiency, low degree of automation, poor machining accuracy, etc., and achieve high automation and improve machining accuracy. and production efficiency, the effect of reducing the material transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

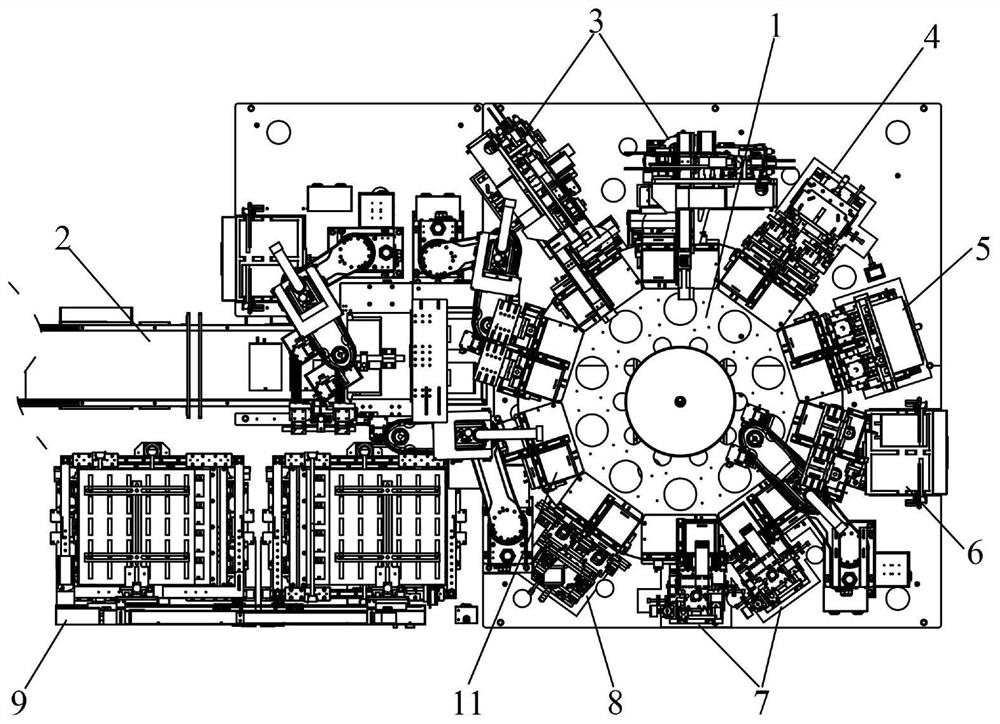

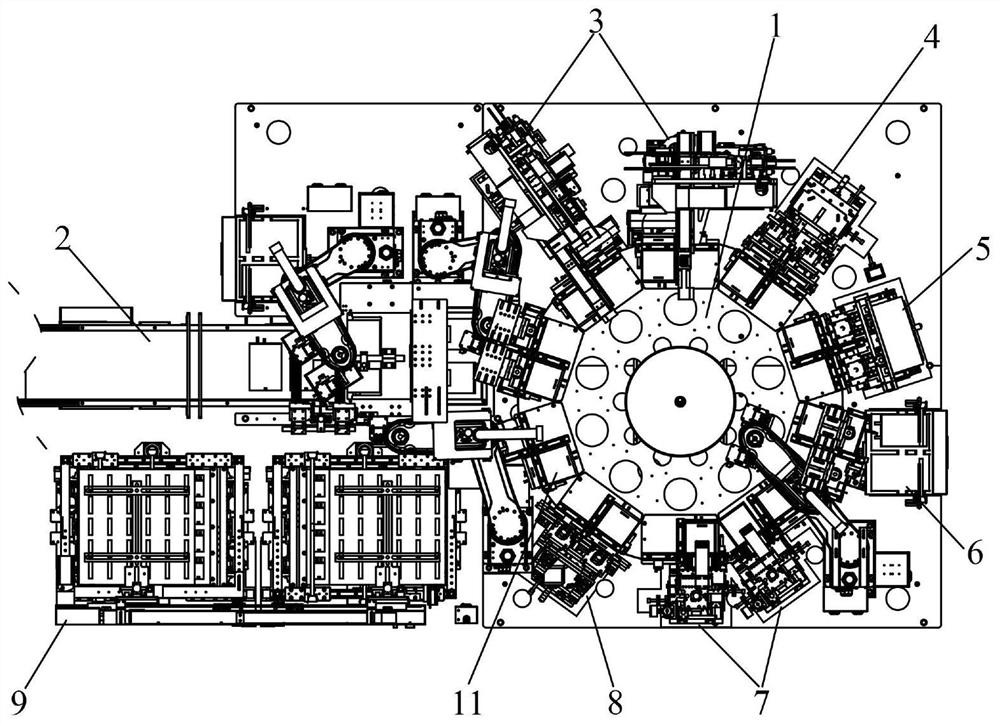

[0041] Such as figure 1 As shown, a battery automatic tail glue corner crimping machine includes a turntable mechanism 1, a feeding mechanism 2, a tail glue mechanism 3, a bottom glue mechanism 4, a glue paper mechanism 5, a horizontal rotation mechanism 6, and a corner folding mechanism 7 , pressing angle mechanism 8 and feeding mechanism 9, several fixed fixtures 11 are arranged on the periphery of turntable mechanism 1, feeding mechanism 2, tail glue sticking mechanism 3, bottom glue pressing mechanism 4, glued paper mechanism 5, horizontal rotation mechanism 6 , knuckle mechanism 7, crimping mechanism 8 and blanking mechanism 9 are sequentially arranged on the outer periphery of the turntable mechanism 1 and correspond to the fixing fixture 11. The feeding mechanism 2 places the battery on the fixing fixture 11 of the turntable mechanism 1, and the turntable mechanism 1 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap