Normal-temperature liquid cheese and preparation method thereof

A cheese and liquid technology, applied in the field of room temperature liquid cheese and its preparation, can solve the problems of inability to store, inconvenient for children to suck, and achieve the effects of preventing cream separation, long-term shelf life stability, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

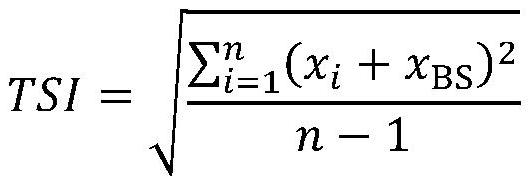

[0024] The preparation method of the room temperature liquid cheese provided according to the embodiment of the present invention comprises the following steps:

[0025] Raw material preparation, cleaning, cutting and subdividing the cream cheese to 3cm×3cm×3cm;

[0026] Hydrate raw and auxiliary materials, mix cream cheese, emulsified salt, sweetener and distilled water at 60-70°C in proportion to obtain a feed liquid; then perform high-speed shearing, the shearing speed is 800-1000rpm, and the shearing temperature is 40~50℃, add emulsifier, stabilizer and resistant dextrin, then stir and mix; add lactic acid, adjust the pH value to 5.4~5.8;

[0027] Melt emulsification, the melting temperature is 80°C, the shear speed is 800-1200rpm, and the shear time is 8min;

[0028] Homogenization treatment, the homogenization temperature is 60-65°C, the first-stage homogenization pressure is 150-180bar, and the second-stage homogenization pressure is 40-60bar.

[0029] Sterilized storage

Embodiment 1

[0037] This embodiment provides a kind of liquid cheese at room temperature, which includes the following raw materials in terms of mass content: cream cheese 51%, emulsifying salt 0.6%, emulsifier 0.6%, stabilizer 0.7%, sweetener 5.5%, resistant dextrin 0.2% %, the rest is water; wherein, the emulsifier is mono-diglyceride fatty acid glyceride, the stabilizer is pectin and hydroxypropyl distarch phosphate with a mass ratio of 1:2, and the sweetener is erythritol with a mass ratio of 1:1 Sugar alcohol and crystalline fructose, emulsifying salt are tricalcium phosphate, sodium hexametaphosphate and disodium hydrogen pyrophosphate in a mass ratio of 1:1:1. Such as figure 1 Shown is the normal temperature liquid cheese provided by the embodiment of the present invention.

[0038] The quality of the room temperature liquid cheese provided in this example reaches the best state, with fine texture, good fluidity, moderate sweet and sour taste, smooth taste and strong milk flavor. At

Embodiment 2

[0040] Using the same method as in Example 1, the difference is that the formula is: cream cheese 51%, emulsifying salt 0.2%, emulsifier 0.6%, stabilizer 0.9%, sweetener 5.5.0%, resistant dextrin 0.2%, The rest is water.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap