Preparation method of wormwood antibacterial coating

A kind of antibacterial coating, wormwood technology, applied in cement coating, antifouling/underwater coating, coating, etc., can solve the problems that affect the coating process and the difficulty of making powder from mugwort leaves, so as to reduce the post-processing cost, anti-virus and sterilization Remarkable effect, achieve long-term health care effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of wormwood antibacterial coating, which comprises the following parts by weight of 600 parts of ionized water, 50 parts of lime, 25 parts of gypsum, 18 parts of white Portland cement, 18 parts of diatom mud, 5 parts of mugwort leaves, and 3 parts of bentonite , 3.2 parts of cellulose.

[0038] Composition is prepared by compound stirring and filtration, and the preparation method comprises the following steps:

[0039] A. Grinding and sieving ingredients:

[0040] The lime is quicklime, ground and sieved, with calcium oxide content ≥ 95%, fineness ≥ 1250 mesh;

[0041] The gypsum is plaster of paris, ground and sieved, with calcium sulfate content ≥ 96%, fineness ≥ 2000 mesh;

[0042] The white cement is white Portland cement, ground and sieved, limestone ≤ 4.5%, fineness 1250 mesh;

[0043] The diatom mud is diatomite powder, ground and sieved, fineness ≥ 300 mesh, diatom ≥ 95%, silicon dioxide ≥ 12%, blue light whiteness 75-95, specific surface a

Embodiment 2

[0059] A preparation method of wormwood antibacterial paint, which further screens the ingredients, and keeps the design of the technical parameters of the processing technology unchanged.

[0060] The batching of described step A is batched according to the following components and weight ratio:

[0061] 520 parts of ionized water, 45 parts of lime, 21 parts of gypsum, 22 parts of white Portland cement, 20 parts of diatom mud, 5 parts of mugwort leaves, 4 parts of bentonite, and 3 parts of cellulose.

[0062] All the other preparation methods are unchanged.

Embodiment 3

[0064] The preparation method of a wormwood antibacterial paint further screens ingredients.

[0065] It is compounded according to the following components and proportions by weight:

[0066] 400 parts of ionized water, 20 parts of gypsum, 52 parts of lime, 30 parts of white Portland cement, 20 parts of diatom mud, 7 parts of mugwort leaves, 3.4 parts of bentonite, and 2.1 parts of cellulose.

[0067] All the other preparation methods are unchanged.

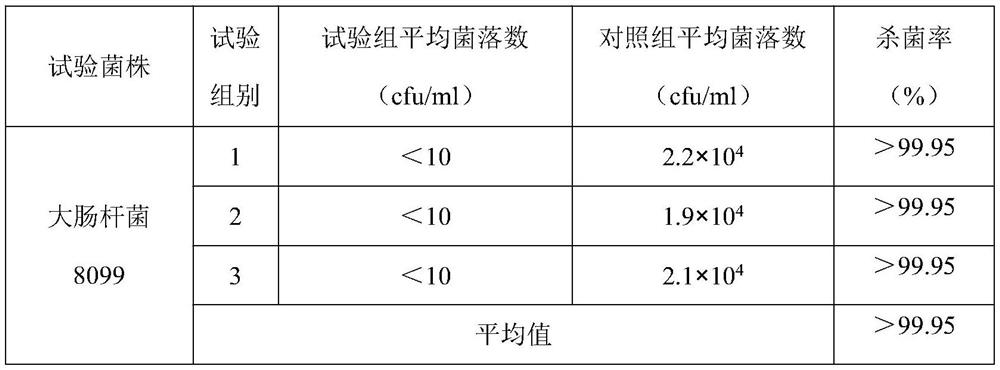

[0068] This patented product uses natural raw materials, no pollution, no radiation, simple preparation process, low cost, the product has been tested and the effective rate of disinfection and sterilization against Escherichia coli is as high as 99.95%. Trichophyton, Epidermophyton flocculus, Microsporum rust-colored, etc. have significant disinfection and sterilization effects.

[0069] The following table is the product efficiency test of the present invention:

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap