Tensioning device for chemical fiber textured yarn

A technology of tensioning device and stretching wire, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems that the tensioning position cannot be adjusted, the tensioning force cannot be adjusted, etc., and it is beneficial to accurate Adjustment, precise rotation angle, smooth transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

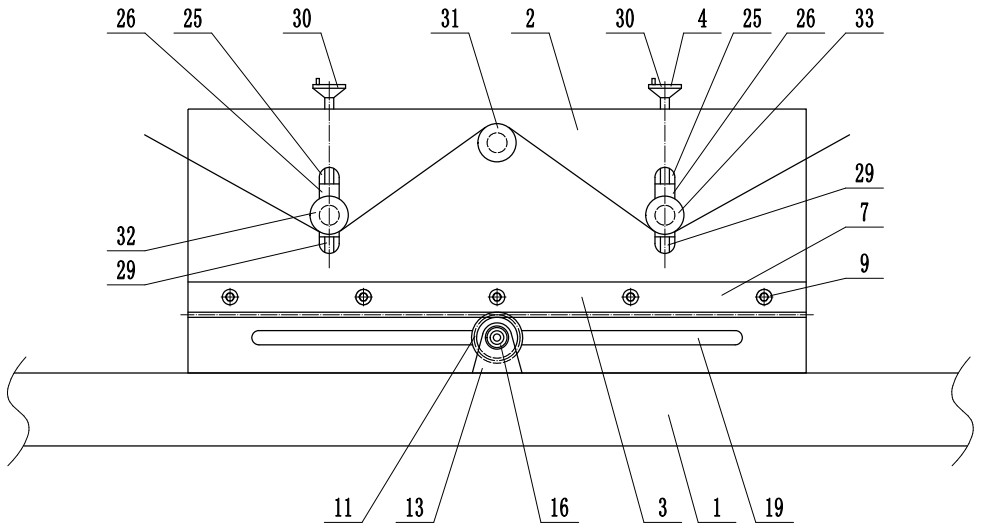

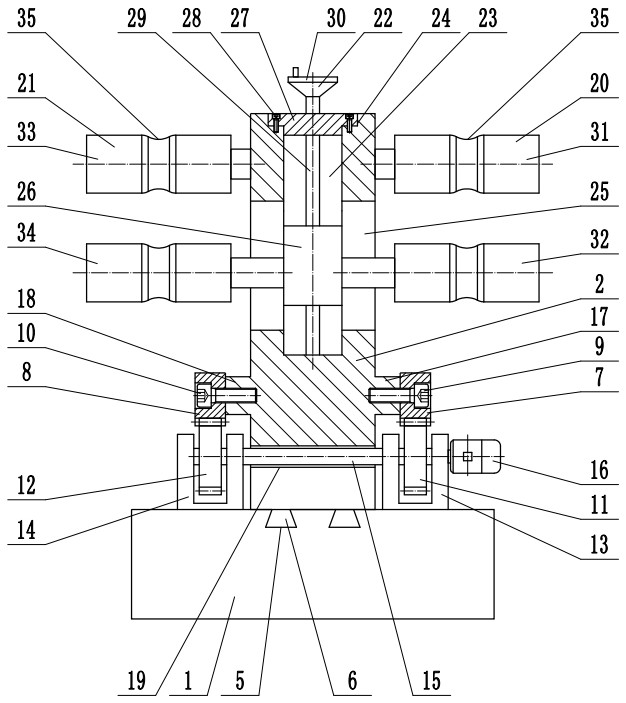

[0014] Such as figure 1 with figure 2As shown in the figure, a tensioning device for chemical fiber stretching yarn includes a frame 1, a tension support seat 2, a tension position adjustment mechanism 3, and a tension force adjustment mechanism 4. The frame 1 is provided with a chute 5 , the lower end of the tension support seat 2 is provided with a slider 6, and the tension support seat 2 can slide left and right through the cooperation of the slide block 6 and the chute 5 and is arranged on the frame 1. The chute 5 is a trapezoidal chute, and the slide block of the tension support seat 2 is an inverted trapezoidal slide block. The structure of the trapezoidal chute and the inverted trapezoidal slide block ensures

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap