Tire vulcanization production line

A tire vulcanization and production line technology, applied in tires, household appliances, other household appliances, etc., can solve the problem of low material filling efficiency and achieve the effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0067] Attached to the following Figure 1-7 This application will be described in further detail.

[0068] The embodiment of the present application discloses a tire vulcanization production line, which is mainly used in the field of tire vulcanization production.

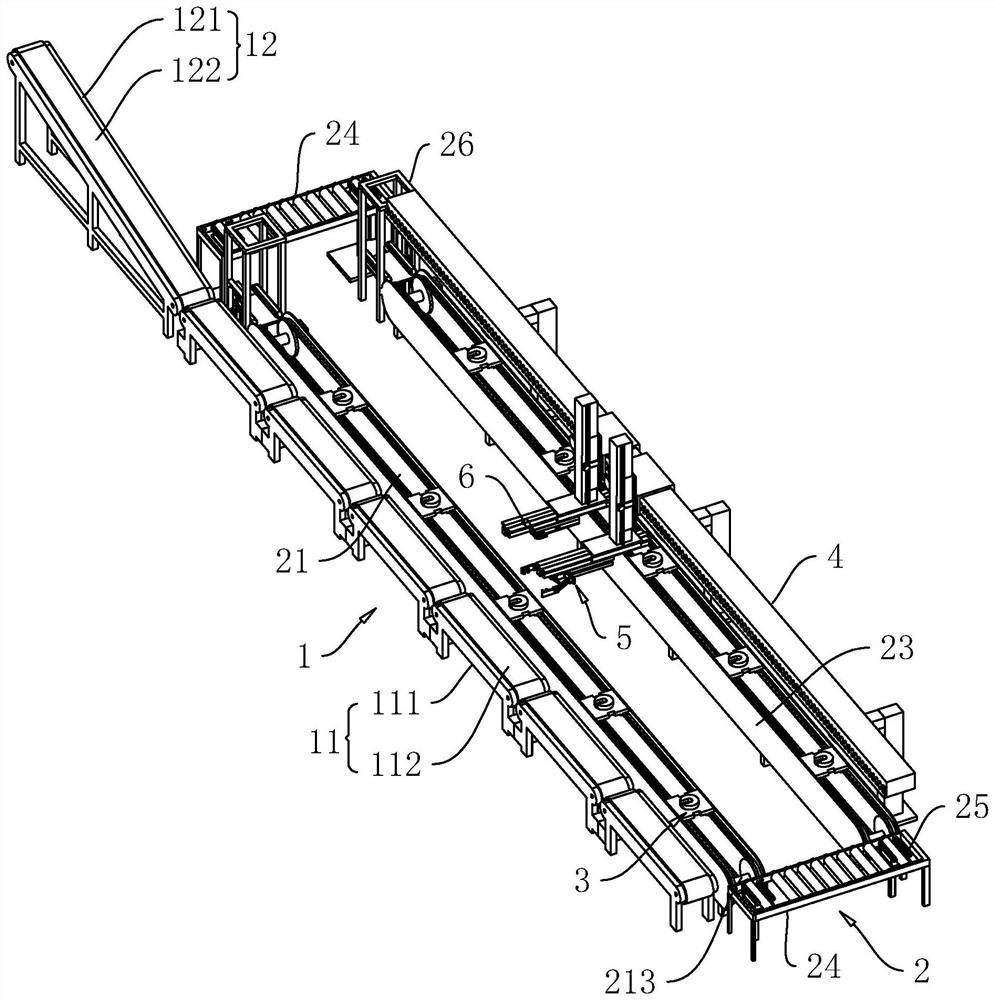

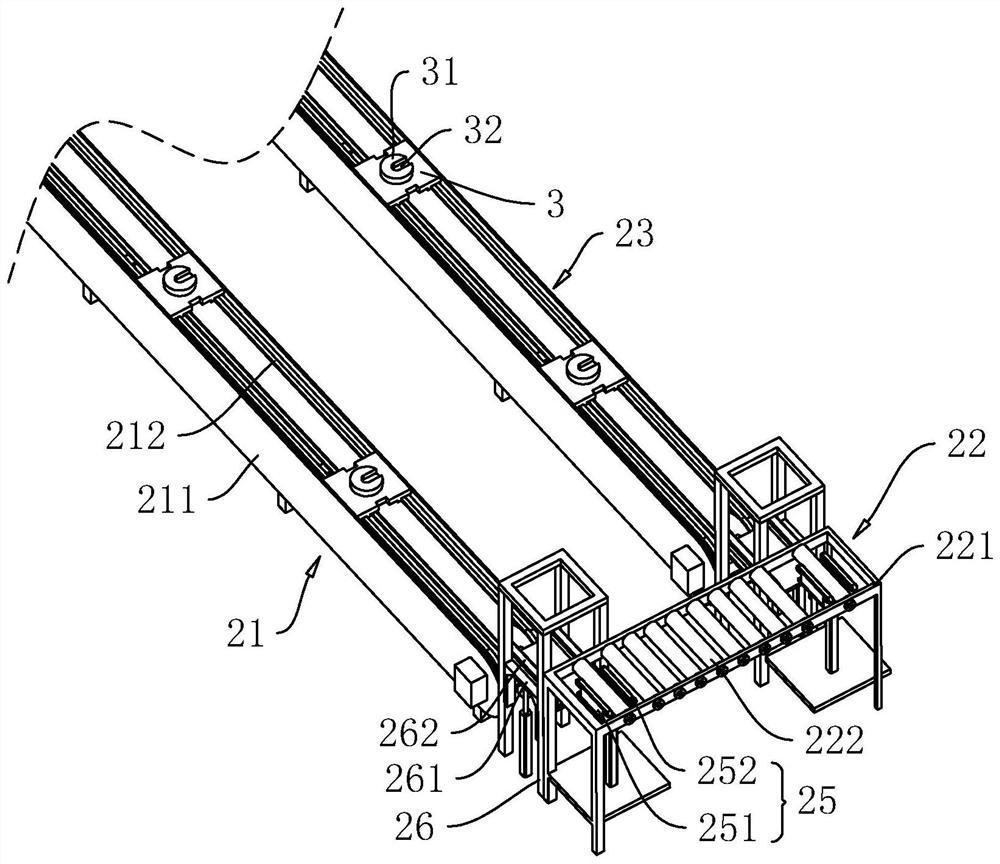

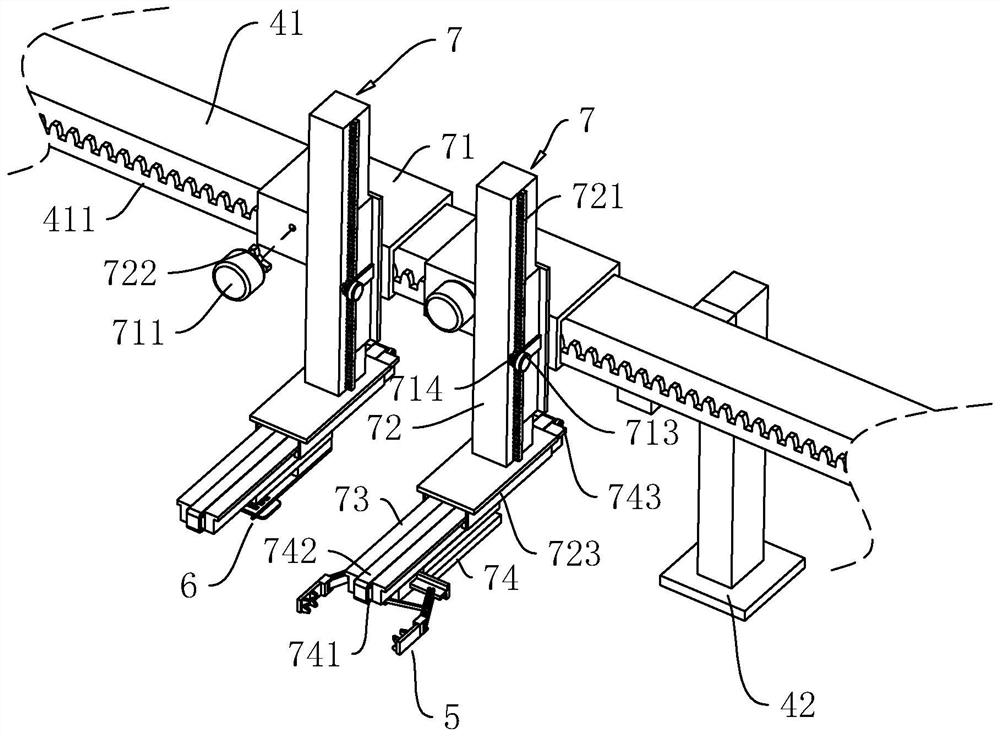

[0069] refer to figure 1 , a tire vulcanization production line, including a discharge conveying system 1, a rotary conveying system 2 and a mobile clamping unit.

[0070] When setting up the production line, firstly, multiple vertical vulcanizers are arranged along the same straight line, and the filler sides of the multiple vertical vulcanizers are all facing the same side. Then, the discharge conveying system 1 is arranged horizontally on the discharge side of the multiple vertical vulcanizers, and the conveying direction of the discharge conveying system 1 is the same as the placement direction of the multiple vertical vulcanizers. The machine-vulcanized tire can be directly placed in the discharge conveying s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap