Production system for blending and filling bottled milk tea beverages on site through robot

A production system and robot technology, applied in beverage preparation devices, bottling machines, bottle filling, etc., can solve the problems of increased operating costs, manual preparation, and low filling efficiency of milk tea shops, and reduce operating costs and labor costs. , The effect of high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example:

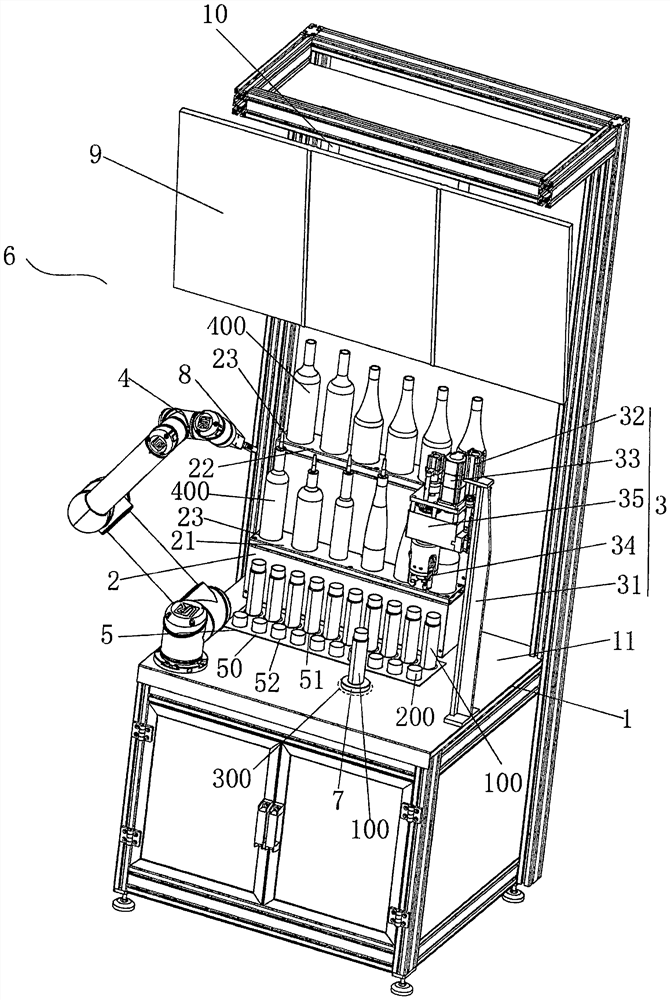

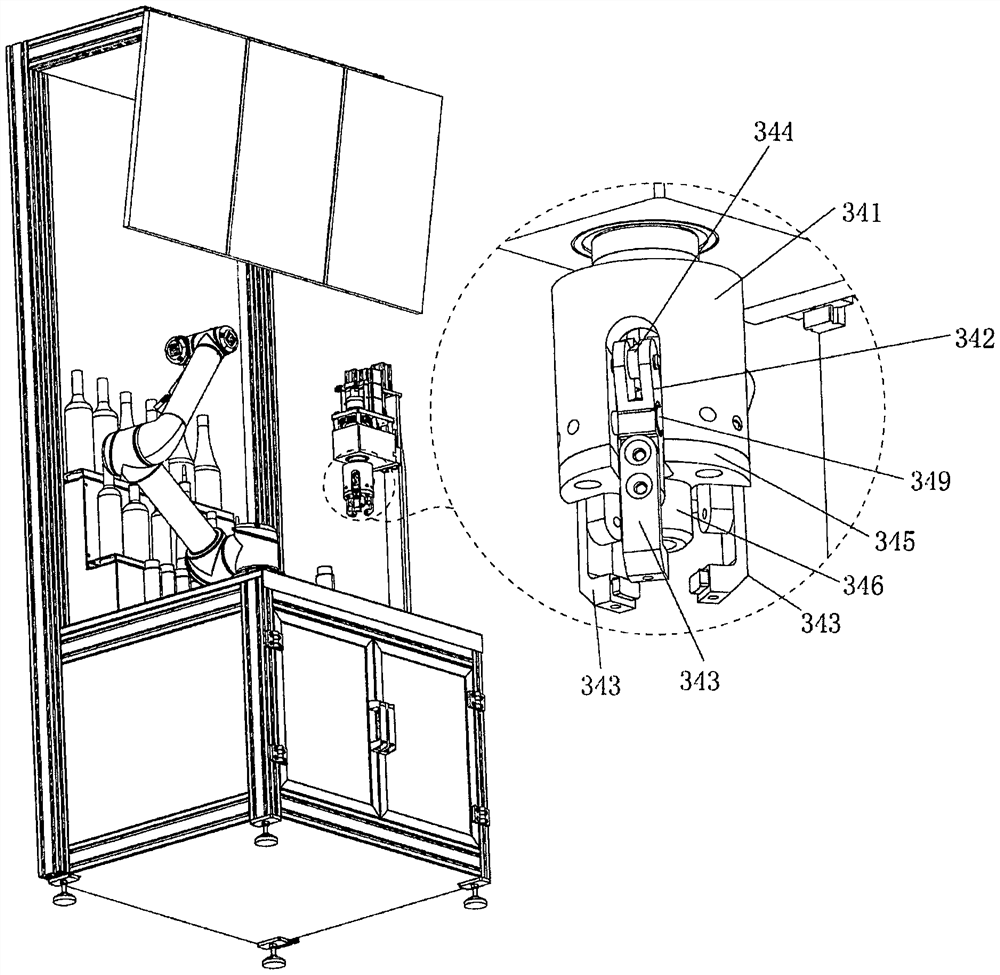

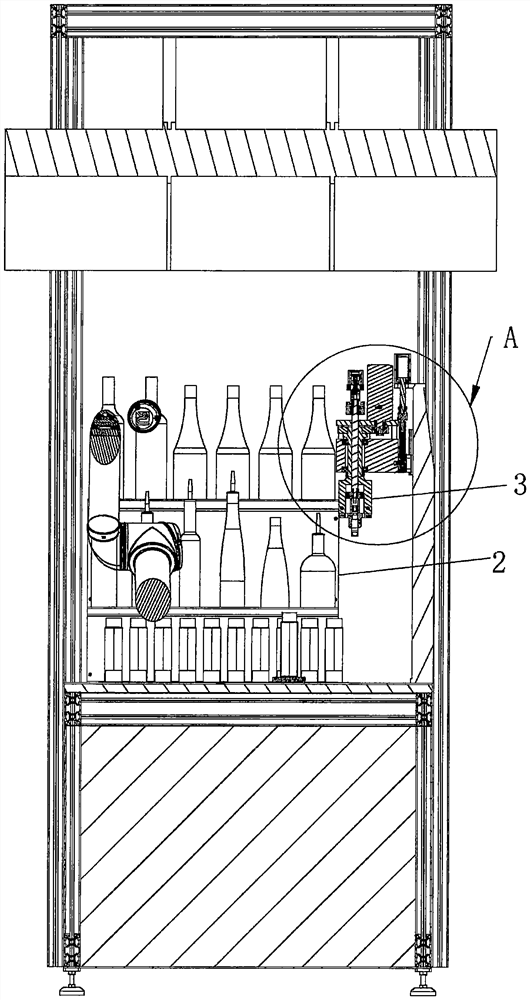

[0030] As shown in the accompanying drawings, the bottled milk tea beverage robot described in the present embodiment is exchanged and filled on the spot production system, including a beverage preparation device 6, a bottle cap tightening device 3 and a PLC controller, the beverage preparation device 6, a bottle cap screw The tightening devices 3 are respectively connected with the PLC controller and controlled by it.

[0031] The beverage preparation device 6 includes a frame 1, and the frame 1 includes a beverage preparation platform 11, a placement rack 2 for placing condiment bottles 400 of various tastes, and a positioning location for a plurality of bottle bodies 100 and a plurality of bottle caps 200 to be positioned. In structure 5, the beverage blending platform 11 is provided with a delivery area 300 and an industrial robot 4, and the industrial robot 4 is equipped with a pneumatic gripper 8; the industrial robot 4 is connected to and controlled by a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap