Flame-retardant elastic rib fabric and flame-retardant fabric

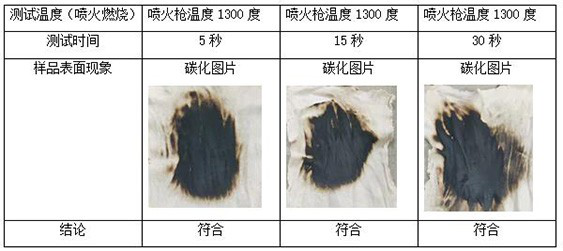

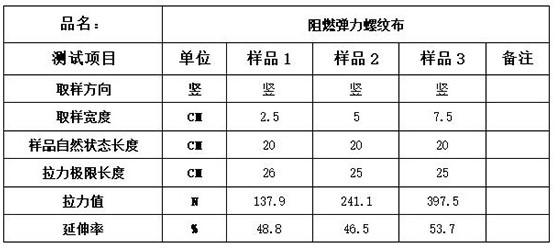

A rib fabric and fabric technology, applied in the direction of flame retardant fibers, knitting, plant fibers, etc., can solve the problems of poor flame retardant effect and non-environmental protection of the fabric, and achieve excellent flame retardant effect, long retention time and good elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] The present application will be described in further detail below in conjunction with specific embodiments.

[0041] A kind of flame retardant stretch ribblin, the ribbed fabric composition is: flame retardant viscose yarn, weight percentage content of 90% (of course, the value can be between 85% -95% of any value, such as 85% or 95%, etc.); elastic wire, weight percentage content of 10% (of course, the value can be 5% -15% between any value, such as 5% or 8% or 12% or 15%, etc.); the above content of flame retardant viscose yarn and elastic wire woven into ribbed cloth, using the following process process:

[0042] Flame retardant coating, the flame retardant and water according to 20:100 by weight (of course, the flame retardant and water by weight can be any value between 10-25:90-110, such as 10:90 or 25:110, etc.) after uniform mixing, and filled into the atomization chamber, the above ribbed cloth is unfolded into the atomization chamber, the ribbing cloth stays in the a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap