Water vapor generating system for maintenance of prefabricated box girder

A generation system, water vapor technology, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems affecting the quality of maintenance, inability to locate, poor spray uniformity, etc., to facilitate transfer or storage, and improve quality , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

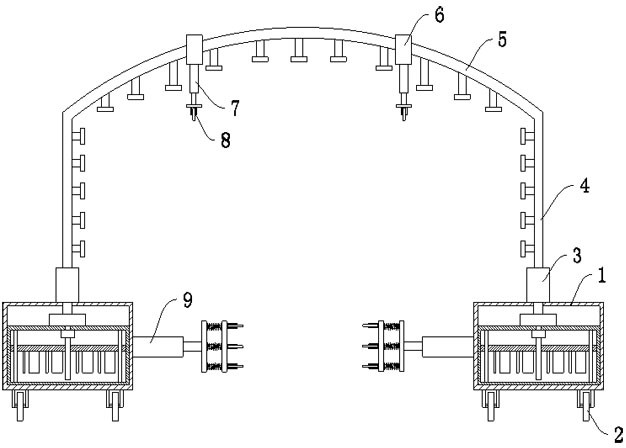

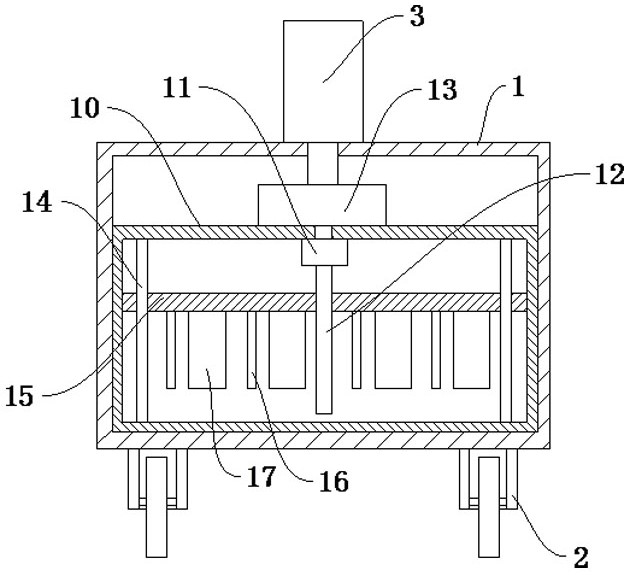

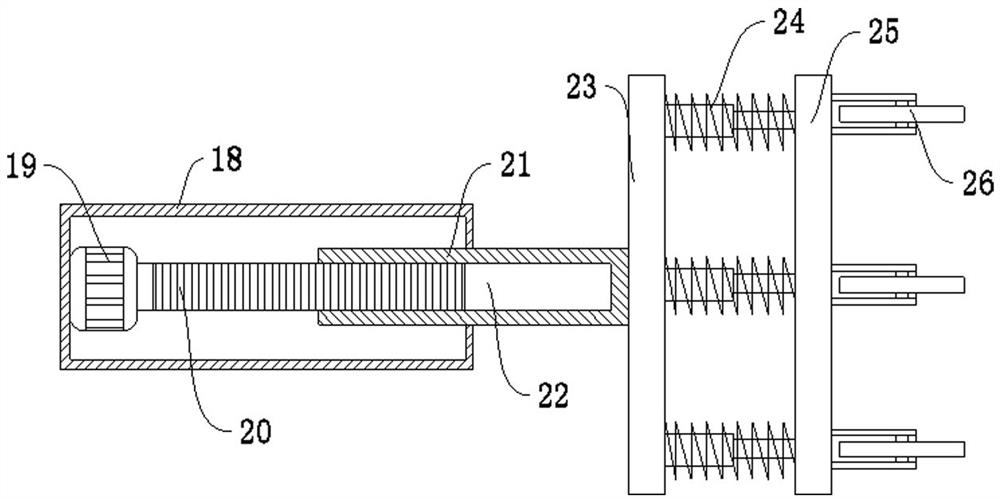

[0036] When working, make the two mobile trolleys 1 located on both sides of the prefabricated box girder, and then open the first telescopic assembly, so that the first guide wheel 26 contacts both sides of the prefabricated box girder, and ensure the expansion and contraction of the two first telescopic assemblies The distance is consistent, so that the first guide wheel 26 is used to clamp the prefabricated box girder to limit the position of the mobile trolley 1, and then use the mobile wheel 2 to move the two trolleys synchronously, and use the vertical spray pipe 4 and the horizontal spray Pipe 5 sprays and maintains the two sides and the upper side of the prefabricated box girder to ensure that the distance between the spraying mechanism and the prefabricated box girder does not change, thereby ensuring the uniformity of spraying and improving the quality of maintenance.

[0037] Two support sleeves 6 are arranged on the horizontal spray pipe 5 , a second telescopic mechani

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap