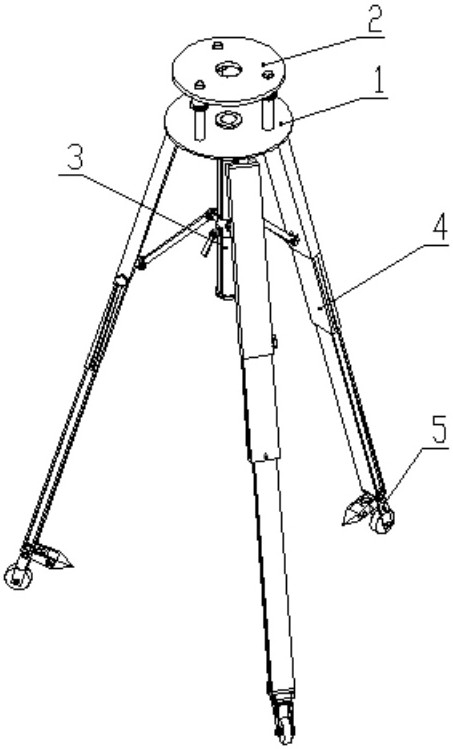

Portable engineering investigation equipment fixing support for road building construction

A technology for building construction and engineering survey, applied in the direction of mechanical equipment, machine table/support, supporting machine, etc., it can solve the problems of unsatisfactory leveling effect of the support foot mount and the inability to quickly adjust the opening angle of the fixed bracket.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

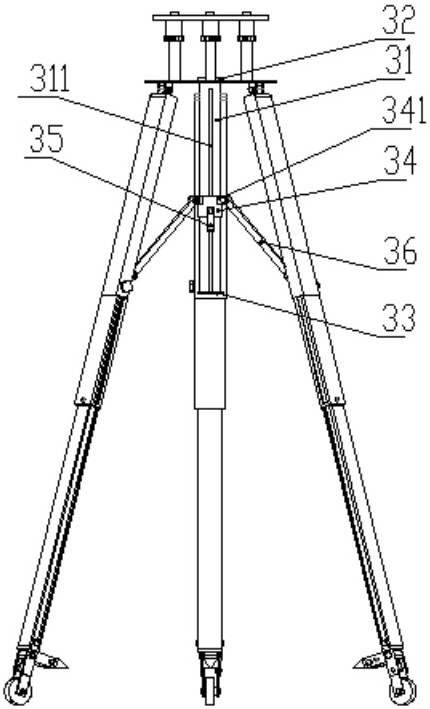

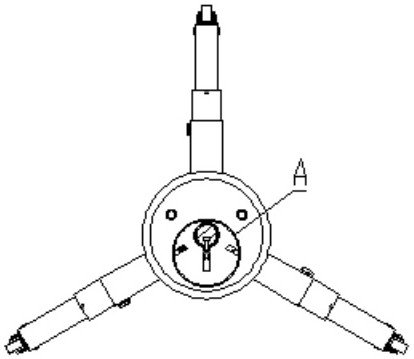

[0038]When the present invention is working, the support mechanism 5 is used to support the fixed bracket, the rotation of the conversion frame 53 is used to select the caster 54 or the toe 55, and the second buckle 56 is used to fix the caster 54 or the toe 55 to realize the support mechanism 5. In the conversion of supporting feet in different working environments, the height of the fixed bracket is adjusted through the telescopic rod 4, and the preliminary adjustment of the height is realized by stretching the third telescopic rod 43 to the position engaged with the second telescopic rod 42. 34 adjusts the position on the slide rod 31, drives the linkage rod 36 to move, and then drives the telescopic rod 4 to rotate around the first rotating seat 11, realizes the adjustment of the opening angle of the telescopic rod 4, and further realizes the opening angle of the fixed bracket and then adjust the height again by adjusting the tension of the second telescopic rod 42. After adju

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap